Failure to lubricate chains and sprockets on industrial and agriculture equipment can wreak havoc on the machine and create unwanted downtime.

Poor lubrication remains the single most common cause of premature failure, and the most time consuming fix. It’s the difference between harvesting the section on time or spending half the day purchasing and installing a new chain.

So, what are the best practices for lubricating those chains and sprockets? Why do they need to be lubricated in the first place?

Here are a few tips to increase uptime and save money on machine parts.

Discussed in this article:

- Why is chain lubrication important?

- When is the best times to lubricate chains?

- What is the best way to oil chains when in operation?

Why is chain lubrication important?

It’s important to remember new chains are not properly lubricated fresh out of the box. The light grease coating chains come with is to prevent corrosion during transit and to assist with the initial install.

Once the chains are in operation, dry chains will become hot with friction and dirty with dust and debris. Ultimately, this leads to failure and breakage.

Frequent maintenance and lubrication of chains is required to reduce friction and keep the pins free of dirt and debris.

When is the best time to lubricate chains?

Motion needs lotion! The proper time to lubricate chains and sprockets is while they are running.

This way, the machine is running, hot, and the chains are warm. Applying a continuous light coating while the machine is in operation will ensure the oil properly penetrates the pins and plates.

What is the best way to oil chains while in operation?

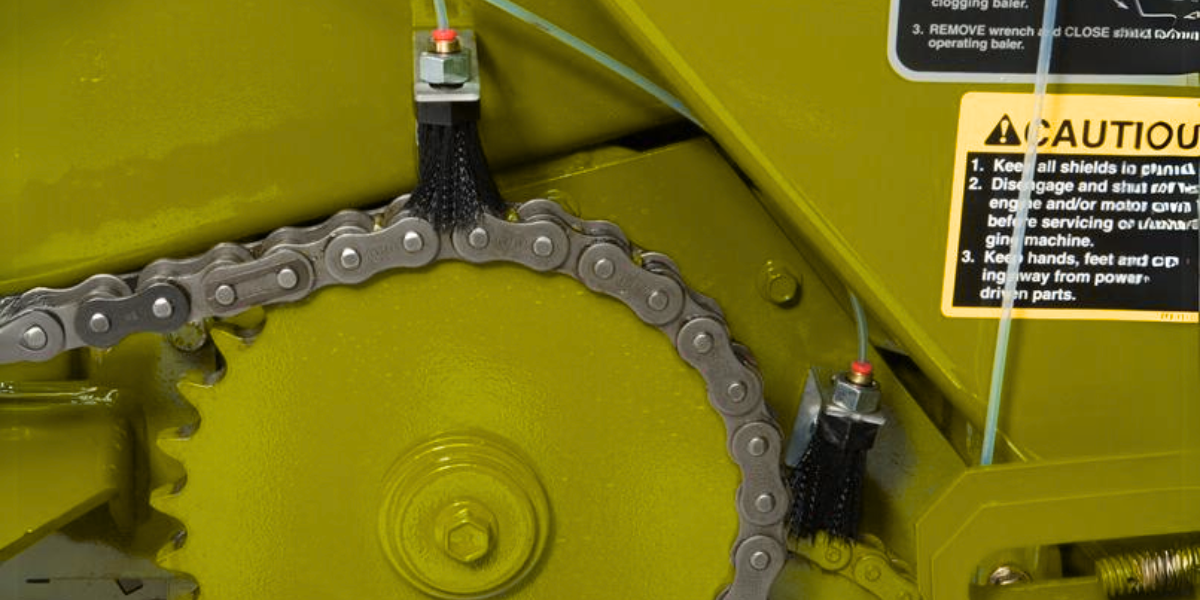

The best way to lubricate chains and sprockets while a machine is in use is with an automatic oiler.

The Automatic Oiler by LubeMinder® is the optimal chain lubrication system for any machine. It doesn't require any electricity because it taps into a hydraulic line and steals the signal to pump oil to multiple chains and sprockets during critical operation periods.

This eliminates the need to manually maintain equipment. It is fully adjustable, safe, and easy to install.

Learn more about the LubeMinder Automatic Chain Oiler at www.lubeminder.com or contact us to speak directly with an expert.

%20Lubeminder%20Contact%20Button.png?width=1200&height=300&name=(1)%20Lubeminder%20Contact%20Button.png)