Lubricants play a crucial role in the longevity of heavy equipment, particularly those used in agriculture. Without proper lubrication, farm equipment can quickly become damaged and even break down, resulting in costly repairs and downtime for farmers.

The most important farm machine to properly lubricate is the baler. It compresses hay or straw into bales for easier storage and transport. Regularly lubricating your baler will help keep it running smoothly and prevent it from breaking down prematurely.

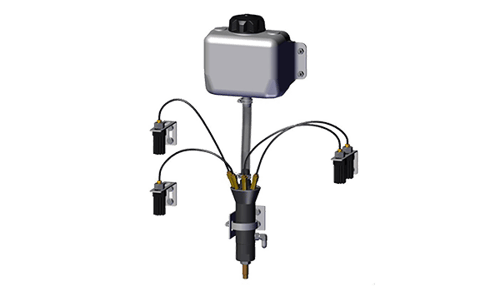

The best way to guarantee upkeep is to invest in an automatic lubrication system.

Baler Operation and Avoiding Breakdown

A baler typically operates by compressing or rolling hay or straw. For the baler to operate smoothly and reliably, proper lubrication is essential. Lubrication helps reduce friction between moving parts. Additionally, it helps keep dust and dirt out of the baler's components, preventing further wear and damage. Because balers typically work in dusty environments, regular chain lubrication can help ensure they remain running efficiently for a long time.

Above all else, an automatic lubricating device can save time, lubricate regularly, and provide reliability during a busy season.

Issues Can Impact a Farmer’s Efficiency

When an agricultural baler is not properly lubricated, a number of potential issues can arise. The lack of adequate lubrication can cause parts to wear down prematurely and create problems with the functionality of the baler. Without lubrication, friction between the moving parts increases drastically, which can cause them to heat up, leading to warped or cracked components.

Additionally, dirt and debris can accumulate around the baler’s components and cause further damage as it moves around without anything to protect it from external elements. Without proper lubrication, the baler may require more energy when operating, resulting in higher fuel costs over time.

Problems that could arise when an agricultural baler is not lubricated properly:

- Premature wear and tear of parts

- Friction causing excessive heat

- Accumulation of dirt and debris

- Higher fuel costs

- Lost time during harvest

- Machine breakdowns

How Baler Automatic Lubrication Saves Time & Money

Farmers have a long list of tasks each day to prep for harvesting and keep operations progressing smoothly. One way to reduce time spent daily is to rely on an automatic greaser that handles the application of farm lubricants without worker oversight.

The right automatic chain-lubricating device:

- Can be installed easily.

- Doesn’t require electricity, which means reliability without pulling additional energy from other systems.

- Doesn’t require a specific manufacturer or brand of oil eliminate worries about keeping the right supply on hand.

- Relies on auto lubrication to reduce daily maintenance to the time it takes to make sure the reservoir is full.

This can mean money and time saved while maximizing harvest time.

Baler Automatic Lubrication | Thinking Ahead to Save

Automatic lubrication is an essential part of the maintenance and operation of this heavy machinery. Without lubrication, the baler would stop working and create a hazardous environment for its operators. The need for lubrication extends to all heavy machinery on the farm.

This is especially important when considering the sensitivity of farm equipment to weather conditions and the large amount of wear and tear it can endure on a daily basis. Automatic oiler systems allow these machines to continue running optimally and help protect them from costly repairs.

Automatic Lubrication Systems Keep You in the Field

Relying on an automatic lubrication system means less room for human error and more time to harvest and resolve other problems. For additional resources to keep your heavy machinery running smoothly, check out the video library or FAQ section of the Lubeminder Learning Center.