Contract Manufacturing

Design | Manufacture | Assemble

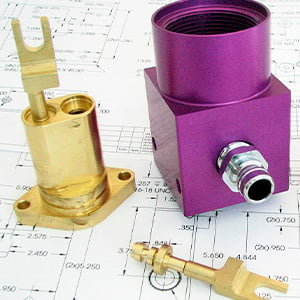

At Suburban Manufacturing, we provide ISO 9001:2015 certified manufacturing services and have built a reputation by completing the most challenging and complex precision projects. Our experienced and knowledgeable engineering and manufacturing teams apply new and innovative technologies as well as lean practices to achieve overall efficiency and reduced production costs.

We provide turnkey solutions; providing full service designing and machining from idea to final product. Our engineers can assist you with the design of your system using SolidWorks technology. Plus our manufacturing and assembly personnel make sure that you get what you need, when you need it.

Our new 50,000 sq-ft facility is home to an impressive inventory of advanced technology machining centers, turning lathes, as well as horizontal and vertical mills. With multi-axis capabilities and productivity-enhancing features such as robotic loaders, automated bar feeds, live tooling, and high-speed pallet changers, we are able to achieve rapid cycle times while emphasizing quality.

Our facility in Monticello, Minnesota offers supply chain agreements for OEMs and large blanket orders. This means taking full responsibility to allocate shelf space for your custom stock parts and planning for future demand spikes. Our priority members can better plan the elimination of stock-outs and raw material shortages.

Product Development

Manufacturing

Vendor Managed Inventory

How can we help you?

We have a plethora of options to help design and create your ideal product.

Services

At Suburban Manufacturing we have a variety of services to best suit your businesses needs. From ideation to creation and for a variety of industries, we have the solution for you.

-

General

- Designing

- Redesign

- Engineering

- Assembly

- Prototype

- Testing

- Reverse Engineering

-

Production Volume

- Specialty Production Shop

- Prototype

- Long Runs

- Medium Runs

- High Volume

- Specialty Production Shop

-

Fixturing

- Pallet Changers

- In-House Fixturing & Tooling

- Pallet Changers

-

Testing

- Pressure Testing

- Life Cycle Testing

- Flow Testing

- Pressure Testing

-

Engineering

- CAD Design Services

- SolidWorks

- Esprit

- Mastercan

- CAD Design Services

-

Value Add

- Deburring

- Anondizing

- Light Assembly

- Managed Inventory

-

Other Services

- Assembly

- Sub Assembly

- Pneumatic Assemblies

- Plating

- Painting

- Heat Treatment

- Ultrasonic Welding

- Thermal Deburring

- Most Surface Coating/Protective Finishes

- Material Processing

Capabilities

Capabilities

There are many capabilities available to complete the production of a new product accurately and timely.

-

Manufacturing Process

- CNC Milling: 3 & 4 axis

- CNC Turning: multi-tasking

- Robotic Loading

- High Speed Machining Centers

-

Machining Processes

- Milling

- Drilling

- Boring

- Turning:

- Contour

- Form Turning

- Taper Turning

- Straight Turning

- Threading

- Tapping

- Thread Milling

- Internal Forming

- Knurling

- Counterboring

- Countersinking

- Pocketing

- Profiling

- Reaming

- Spline

- Parting/Cutting

- Facing

- Burnishing

-

Equipment Capabilities

- Bar Feed

- Milling – Vertical & Horizontal with pallet changer

-

Machining Axis

- 2, 3, & 4 axis

- Lathe Sub-Spindle

- Live Tooling

-

Tolerances

- ±.0005”

-

Size Capacity

- Milling Max 19" x 30"

Machines

Machines

The machinery required to build the product you're looking for efficiently.

-

CNC Lathes

- Daewoo Puma 240L

- Doosan Puma 240MB

- Doosan Lynx 220LC

- Doosan Lynx 220C-NT

- Doosan Lynx 300M

-

Turning Centers

- Nakamura-Tome NTY3 100 CNC Turning Center - 2019

- Doosan Puma 2100SY CNC Turning Center

-

Machining Centers

- Makino a51nx Horizontal Machining Center - 2019 & 2021

- Kitamura MyCenter HX400G Horizontal Machining Center - 2015

- Fanuc RoboDrill Vertical Machining Center

-

Mills

- Haas VF-4SS Vertical Mill - 2020

Materials

Materials

Material options for products.

-

Metals

- Aluminum

- Brass

- Bronze Alloys

- Carbon Steel

- Iron

- Stainless Steels

-

Plastic Polymers

- ABS

- Acetal

- Acrylic

- Nylon

- Polycarbonate

- Polyethylene

- PVC

- PTFE

.png?width=210&height=116&name=Suburban%20LOGO%20-%20Pantone-01%20(1).png)

.png?width=210&height=113&name=Suburban-Manufacturing-Group-Logo%20(2).png)