3 min read

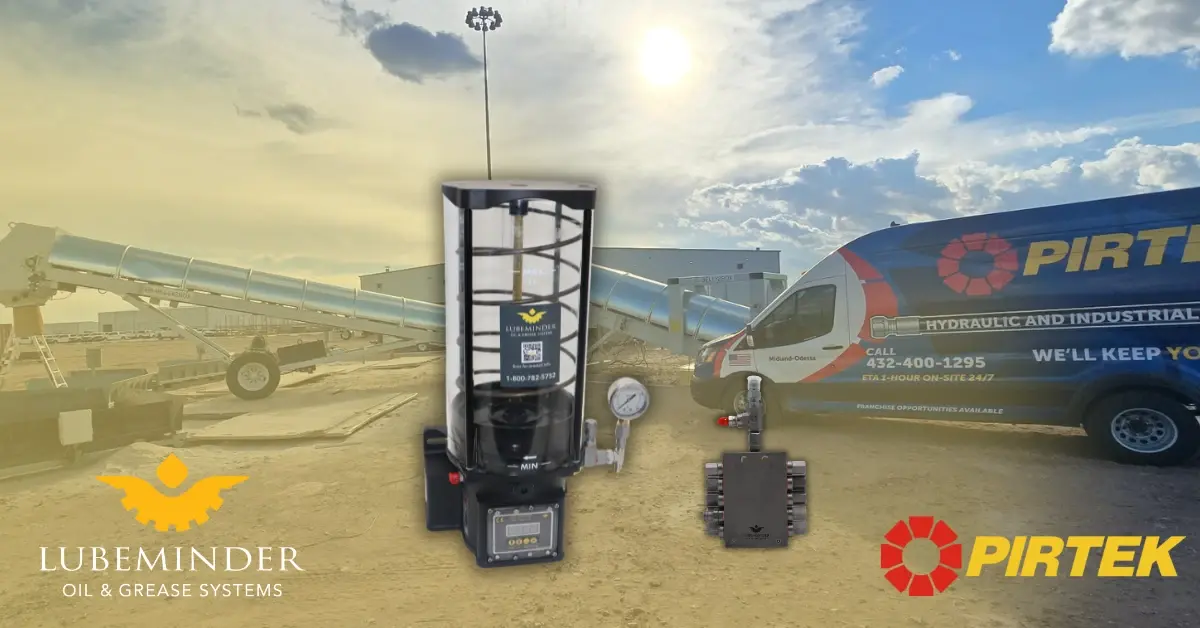

Case Study | Pirtek Installs Electric Grease System on a Gravel Conveyor

LubeMinder Team

:

Dec 9, 2025 5:04:47 PM

Industry: Aggregates

Industry: Aggregates

Application: Gravel Conveyor

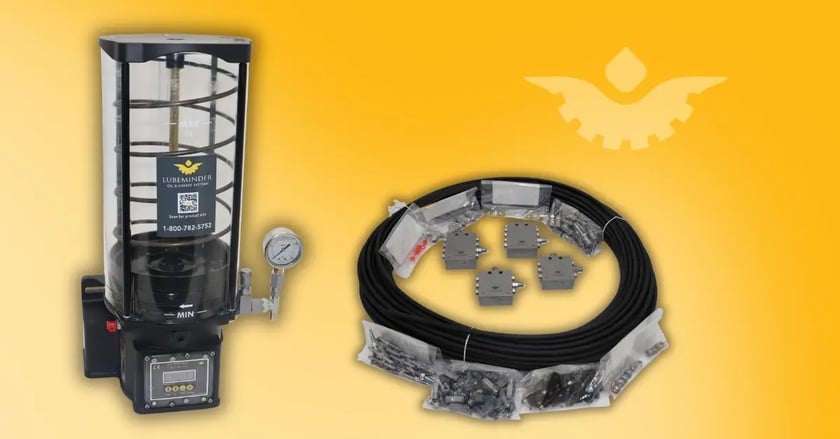

System Installed: LubeMinder® Electric Grease Pump + Progressive Blocks

From an Emergency Repair to a High-Value Customer

This project began late on a Friday night, when Pirtek Midland–Odessa received an emergency call about a gravel conveyor that urgently needed service. Derrick left dinner to respond and began troubleshooting what initially seemed like a hydraulic or grease line issue.

Once onsite, he discovered the customer had been experiencing recurring lubrication failures with a competitor’s system: bearing failures, unreliable grease output, and difficult-to-source parts.

During the repair, Derrick let the customer know he was in the process of becoming a LubeMinder installer. Their response was immediate and positive, they were ready to move on from their previous lubrication setup and wanted a more reliable and serviceable system.

“LubeMinder turned an emergency repair job into a major customer.”

- Derrick

Conveyor in Need of an Updated Lubrication System

A smooth, supported ordering & setup process

After Derrick inspected the machine and gathered bearing details and photos, he sent the information to Suburban Manufacturing.

Within just a few days, Jason with Suburban provided a complete quote and system layout, giving Derrick everything he needed to present a solution.

When the customer decided to move forward, Suburban quickly built the system and shipped it out with expedited delivery so the conveyor could be deployed on schedule.

LubeMinder Kit Built for Pirtek

Installation: faster every time

The first installation took about five days as Derrick learned the machine layout and determined how much grease line was required. The conveyor spans 35–40 feet per section with 16 lubrication points, and the team ended up being about 250 feet short on line, something that could only be learned by seeing the equipment in person.

“There wasn’t anything Suburban could have done differently on that first install, we just had to see it ourselves.”

- Derrick

Once familiar with the setup, installation time dropped dramatically.

Their second install, on a similar conveyor in North Dakota, was completed in under 48 hours.

Their third install was also quick, delayed only slightly due to weather.

Derrick noted several aspects that made the installs smoother:

- Jason’s install guide/map: “This made the process easy and understandable.”

- Modular layout: Allowed them to complete the install in phases.

- Flexibility to install with or without a welder: “We welded on threaded bolts, but most of the system can be mounted without one.”

Gravel Conveyor with Progressive Blocks and Grease Lines Installed

Reliable Performance & Positive Customer Feedback

The system has been operating since mid-September and has had zero reported issues.

Feedback from the customer has been consistently positive:

- Operators have been easily trained on the system.

- The pump is simple to maintain.

- The customer appreciates having a more dependable, streamlined solution than their previous lubrication setup.

Derrick noted they are using a pneumatic barrel setup to fill the grease reservoir and prefer not to use quick-fill fittings.

With additional conveyors scheduled, the customer is confident in continuing with LubeMinder systems across their equipment.

Gravel Conveyor

Impact on pirtek midland-odessa's business

Offering LubeMinder lubrication systems has already expanded their business opportunities.

After Derrick posted their first installation on LinkedIn, he immediately received an inquiry from a local heavy equipment dealer. Derrick noted there is very limited local competition for automatic grease systems, which positions them strongly for growth.

These installs bring ongoing value to the business:

- A growing customer base

- Opportunities for lubricant sales

- More recurring service touch points

It also opens new industry segments:

“Aggregates is new for us. We’ve done a lot of LubeMinder product with them already.”

Derrick also shared another key insight:

“The LubeMinder system is a high-value item we can offer with zero special tooling or shop requirements.”

LubeMinder Grease Pump with Gauge

Closing thoughts from derrick

- Advice for new installers: “Ask questions, expect the first install to be rocky but very easy to learn from.”

- How he describes the system: “Complex but understandable and trainable.”

- Final thoughts: “Take your time learning the system. Under-promise results and over-deliver.”

He also provided written feedback to his franchise consultant:

“The support from LubeMinder has allowed us to compete and be experts on their product offerings. We’ve found very little competition in this side of the industry, and customers who need lubrication solutions are a great fit for our Pirtek products.”

Explore our Grease Systems or connect with LubeMinder to start building your custom solution today.