3 min read

How to Pick Progressive Distributor Blocks for Your Lubrication System

LubeMinder Team

:

Sep 11, 2025 8:00:00 AM

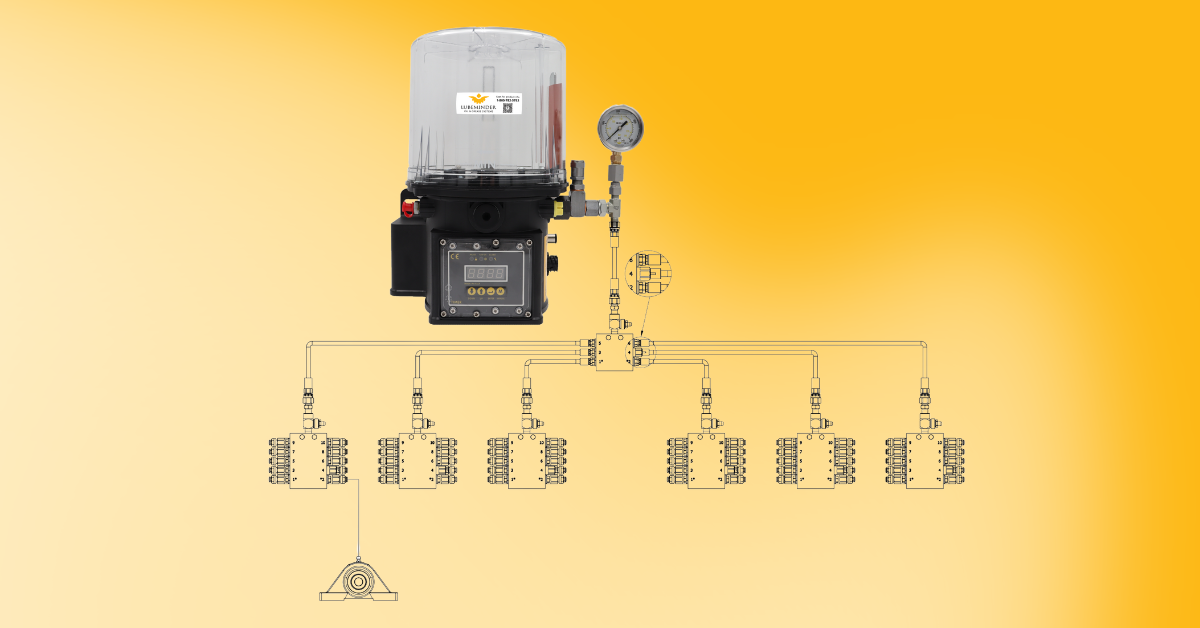

Industrial lubrication systems are automated or manual mechanisms that deliver lubricants, like oil or grease, to reduce friction, wear, and heat on moving parts. They ensure reliable operation, minimize downtime, and decrease maintenance costs in your production equipment.

A critical component of the lubrication system is the distributor block. A reliable distributor block optimizes the lubrication of your machinery. Without a good one, production could come to a screeching halt.

In this article, we’ll discuss lubrication systems and the critical role of progressive distributor blocks, as well as key factors to consider when choosing your grease and oil systems.

What is a Progressive Distributor Block?

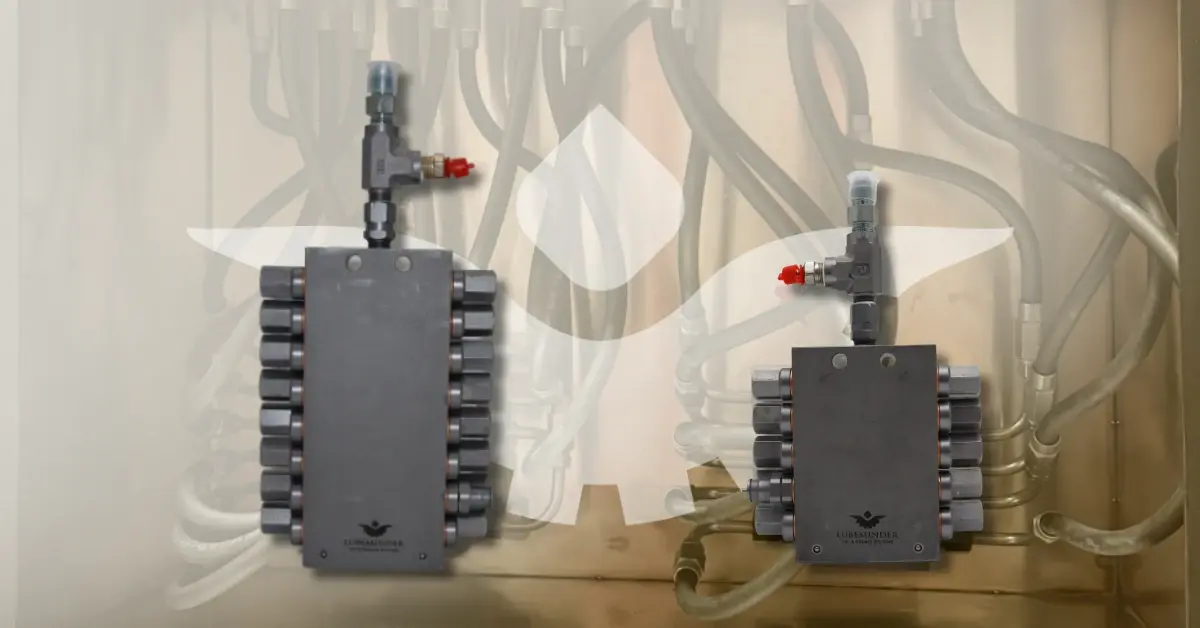

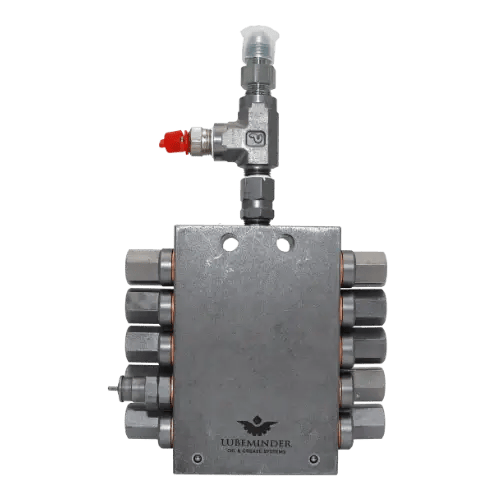

The distributor block operates as part of the overall progressive lubrication system. These blocks have multiple ports designed to efficiently and accurately distribute lubricant. The lubrication is supplied directly from the pump to the progressive block, which distributes lubricant evenly to many different grease points.

An oil and grease distribution block is key to the performance of the progressive grease system.

These blocks help keep equipment running at its best by monitoring which points need maintenance. Monitoring what your equipment needs extends its life, minimizes downtime, and improves production efficiency. Plus, it enhances workforce safety by enforcing proper upkeep of machinery.

Key Factors in Choosing a Distributor Block

Progressive distributor blocks are not a one-size-fits-all part for your machinery. These blocks are custom-fitted to provide the precision required for delivering grease or oil throughout the system. Therefore, there are key factors to consider when choosing a distributor block for your lubrication system:

- Number of lubrication points

- Environmental and operating conditions

- Discharge volume

- Lubricant type

- Bushing and bearing size

Number of Lubrication Points

When choosing your progressive block, it's critical to match the block to the existing system layout. First, determine the number of lubrication points in your system. This will dictate the size of your block, as well as the number of lubrication ports needed on the block.

Consider your needs further down the road, too. Choosing progressive lubrication systems that allow for expansion makes it easier for you to adapt if more points of friction are added to the system later on.

Environmental and Operating Conditions

What type of environment does your machine operate in? Each type of environment requires different specifications. Take into consideration:

- Temperature

- Moisture

- Contaminants in the air

This will affect the type of material best suited for your distributor block. For example, in rock crusher equipment, the progressive block must withstand increased force while maintaining accurate lubricant delivery.

Additionally, factor in any special requirements. Is the equipment found in a food prep area? The distributor block will need to be made out of food-grade materials for sanitary environments.

Discharge Volume

Define the required discharge volume as you decide on your progressive block. Base this on your equipment’s specifications. Does your system need a fixed or an adjustable amount of lubricant? Other factors to consider include the viscosity of the lubricant, as well as the required precision for each lubrication point.

Lubricant Type

Consider whether your machine uses grease or oil as a lubricant to ensure compatibility with the distributor block. The work environment and the materials of your machinery also play a part in determining the ideal type of lubricant. For example, restaurants require food-grade lubricants, while other environments must account for potential chemical interactions.

Bushing and Bearing Size

The size of your bushings and bearings directly affects the lubricant volume and pressure requirements. Larger bushings and bearings require more lubricant to protect against friction and wear, while smaller ones need less lubrication to avoid waste and overheating. The proper distributor block ensures each part of the system receives the correct amount of grease or oil.

Additional Factors to Consider When Choosing Your Progressive Distributor Block

In addition to the must-haves, there are a few other considerations when selecting your distributor block for your oil and grease system. These include:

- Maintenance and monitoring capabilities: Do you want a progressive block that allows for easy inspection, maintenance, and performance tracking? These can help improve production efficiency and extend the lifespan of your equipment.

- Cost and life cycle considerations: What is your budget? Will you be able to keep up with maintenance checks? This helps with the durability and longevity of your distributor block.

- Type of lubrication system: As you research distributor progressive blocks, consider how your current lubrication system functions. Is your system manual or automated? This will influence which blocks will work with your current system.

Common Mistakes in Choosing a Progressive Distributor Block

Common Mistakes in Choosing a Progressive Distributor Block

Choosing the wrong progressive distributor block can lead to costly breakdowns and stops in production. Watch out for these common mistakes when choosing a progressive distributor block for your lubrication system:

- Underestimating lubricant requirements for your system: Using a progressive block that isn’t compatible with the type of lubricant can lead to improper lubrication and increased wear and tear on equipment.

- Overlooking system compatibility: If the progressive block doesn’t fit with the existing system, it won’t perform effectively, which could cause major problems in your production.

- Basing your decision on price versus system fit: Don’t choose a progressive block simply because it's the cheapest, unless you want to risk poor performance, higher maintenance costs, and decreased durability.

Your Machinery Depends on the Right Progressive Distributor Block

Choosing your next progressive distributor block is more than just a simple swap of off-the-shelf parts. It directly impacts your entire lubrication system. Its reliability, efficiency, and longevity could be compromised if you don’t consider the key factors of your system – from the number of lubrication points and discharge volume requirements.

Your machinery depends on a steady flow of lubricant to keep production going. Find the perfect fit for your lubrication system in our full catalog of products, which includes progressive distributor blocks and other lubrication parts that will help keep your business running at peak performance.