2 min read

Hydraulic vs Pneumatic Lubrication Systems: What's the Difference?

LubeMinder Team

:

Oct 5, 2023 12:41:03 PM

Hydraulic and pneumatic lubrication systems are both useful additions when it comes to keeping equipment slick and running smoothly - but what's the difference between the two? We will dig into the specifics so it's easier to decide which LubeMinder oiling system is best for your application.

In this article we'll discuss:

- What Lubrication Systems Do

- How Our Lubrication Systems Work

- Hydraulic vs Pneumatic Lubrication Systems

- Why You Should Invest in a LubeMinder Automatic Oiler

What Lubrication Systems Do

Lubrication systems are designed to deliver the perfect amount of lubrication at the right time to your equipment. This keeps production running, and avoids downtime. Thanks to these systems, gears and sprockets are maintained so equipment performance and function remains optimal.

How Our Lubrication Systems Work

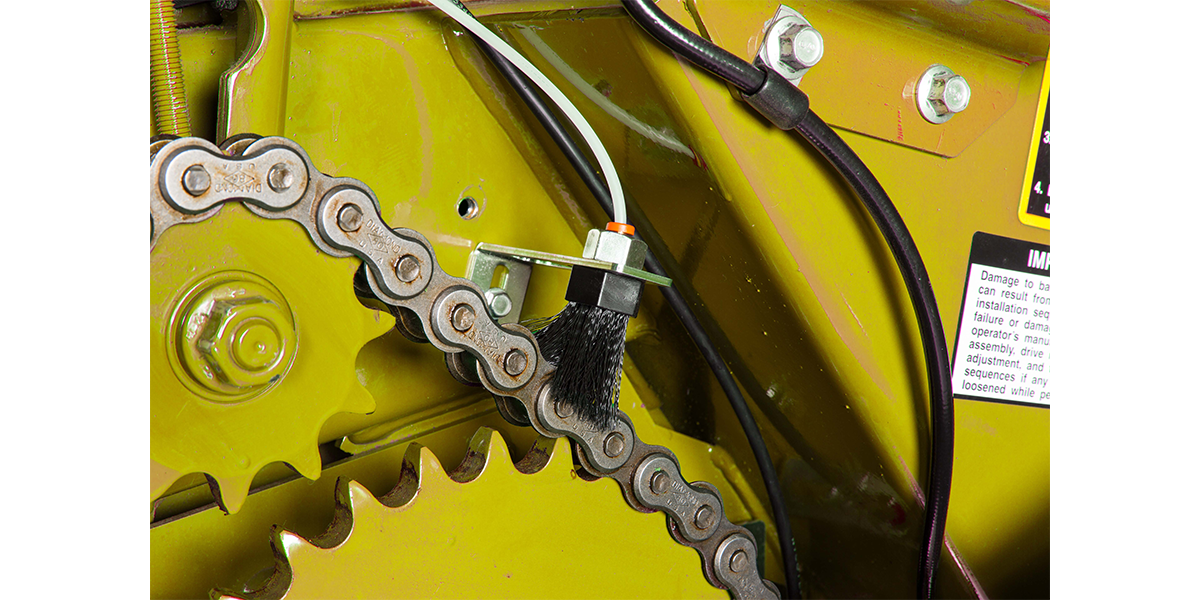

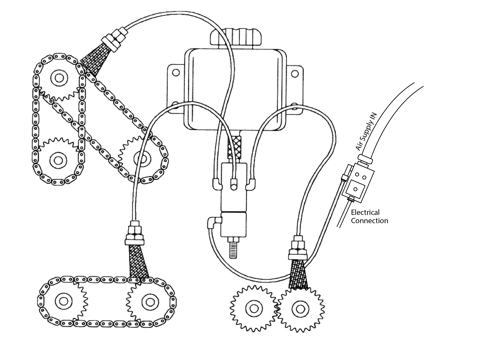

Lubrication systems all work similarly. A piston in the pump is actuated by a hydraulic pilot signal which pushes oil down line. The lubricant is then dispersed via brushes, which also clean the chains of dirt and debris. The brushes also evenly disperse the oil to the application. This ensures the systems apply oil consistently as the chain is warm and running, and works to minimize the possibility of metal-to-metal contact while cooling the equipment's joints as it's applied.

Applications for Automatic Oilers

From farming to forestry, there are many different applications for an automatic oiling system. These include:

- Harvesting & planting equipment

- Fertilizing machinery

- Concrete pumps and machinery

- Forestry equipment

- And more!

Hydraulic VS Pneumatic Lubrication Systems

Hydraulic and pneumatic lubrication systems share the same purpose: to reduce time spent maintaining industrial equipment, increase productivity, and the life of capital equipment. What differs is what powers them throughout the process.

Similarities and Differences

Both hydraulic and pneumatic LubeMinder oilers carry out the same function and achieve the same results as stated above. Other similarities:

- Increase chain life by 3 times: specifically engineered brushes clean chains and sprockets while applying oil to all moving parts.

- Climate control: fully adjustable pump allows modification of dispensing rate and ensures all chains and sprockets are properly oiled regardless of climate or condition.

- Eliminate downtime: lubricating while parts are warm and running allows oil to penetrate pin and brush joints.

- Increase resale value: machinery that is well maintained and fully equipped retains higher value for resale.

- Save you money on chain replacement: longer lasting chains means less downtime and lower costs associated with chain replacement.

The Difference:

- Hydraulic lubrication systems are actuated from a hydraulic pilot signal that does not trap pressure. Like a cylinder that opens the lift gate on a round baler.

- Pneumatically driven systems pump air into an air supply line with 60+ PSI.

Any air line on a piece of machinery that periodically sends an air signal could work. The pump is then actuated by an electronic timer controller.

why you should invest in a Lubeminder Automatic Oiler

Investing in a LubeMinder Automatic Oiler for your machinery is a smart decision that can greatly benefit your operations. These systems are designed to deliver the perfect amount of lubrication at the right time, ensuring optimal equipment performance and function.

By consistently applying oil to gears and sprockets, an automatic lubrication system helps to minimize the possibility of metal-to-metal contact, while also cooling the equipment's joints. This not only extends the life of your machinery, but also eliminates downtime, saving you money on chain replacement and increasing resale value.

Whether you're in the farming, forestry, or concrete industry, an automatic oiling system can greatly enhance the efficiency and productivity of your equipment. Don't miss out on the opportunity to improve your operations - invest in a LubeMinder Automatic Oiler today!