2 min read

Why NLGI #1 Grease Outperforms NLGI #2 in Cold Weather Conditions

LubeMinder Team

:

Oct 28, 2025 5:00:00 AM

When it comes to equipment reliability in cold weather, one often overlooked factor is the type of grease used for lubrication. Many maintenance professionals default to NLGI #2 grease, which is commonly used in a wide range of applications. However, as temperatures drop, using NLGI #1 grease can offer significant advantages, particularly due to its lower viscosity and better flow characteristics in cold environments.

Understanding NLGI Grades and Viscosity

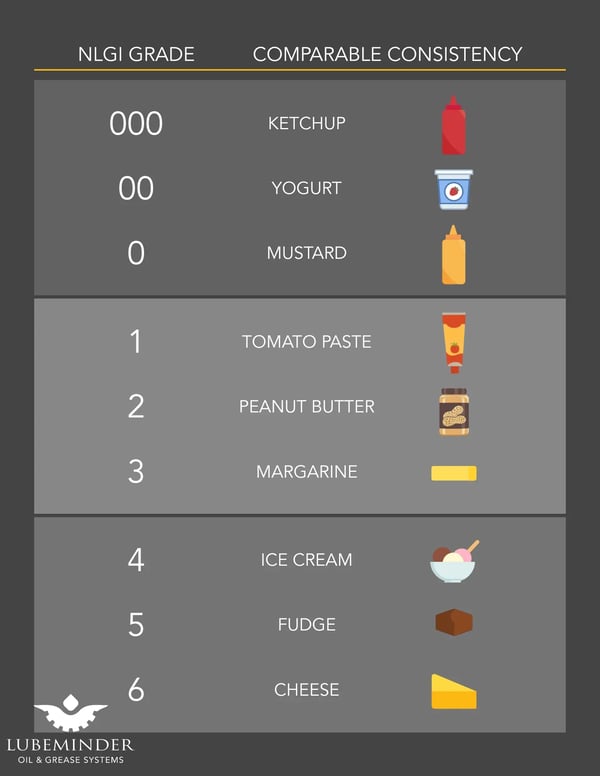

The National Lubricating Grease Institute (NLGI) classifies grease consistency on a scale from 000 (fluid-like) to 6 (block-like). The most common grade, NLGI #2, has a peanut butter-like consistency, while NLGI #1 is softer, more like a tomato paste.

While the NLGI grade doesn't measure actual viscosity, it correlates to how easily grease can flow, especially at varying temperatures. In cold environments, the ability to flow becomes critical.

The Problem with NLGI #2 Grease in Cold Environments

In lower temperatures, NLGI #2 grease thickens and becomes more resistant to movement. This increased stiffness can lead to:

- Poor pumpability in centralized lubrication systems

- Insufficient lubrication at start-up

- Increased energy consumption due to resistance and bearings or other moving parts

- Premature wear or failure of components that aren't receiving proper lubrication

These issues not only compromise equipment performance but can also lead to unexpected downtime and higher maintenance costs.

Why NLGI #1 Grease is a Better Fit for Cold Weather

NLGI #1 grease, with its lower consistency and better flow characteristics, performs much more reliably in cold weather. Here's how:

Improved Pumpability

Colder temperatures reduce the efficiency of grease delivery systems. NLGI #1 grease flows more easily through lines, valves, and fittings, making it ideal for automatic or centralized lubrication systems in cold environments.

Faster Lubrication on Start-up

Machines and vehicles operating in sub-freezing temperatures need instant protection. NLGI #1 grease reaches friction surfaces faster, reducing wear during cold starts.

Reduced Mechanical Drag

Grease that's too thick can cause resistance, leading to increased torque and energy use. NLGI #1 reduces drag on moving parts, allowing systems to run more efficiently when temperatures drop.

Better Bearing Protection

Cold-thickened grease may not reach the entire bearing surface, leaving spots vulnerable to wear or corrosion. NLGI #1's lower viscosity helps ensure more complete coverage.

Maximize Cold Weather Lubrication with LubeMinder® Automatic Grease Systems

To take advantage of NLGI #1 grease in cold weather, it's important to pair it with a reliable delivery system; that's where LubeMinder Automatic Grease Systems come in. Designed to keep equipment properly lubricated without manual intervention, LubeMinder systems are built to handle lower viscosity greases like NLGI #1 making them ideal for cold weather applications.

Whether you’re running ag equipment, industrial machinery, or heavy-duty vehicles, LubeMinder ensures your components are lubricated consistently, efficiently, and automatically, even when temperatures drop well below freezing.

- Reduce downtime

- Extend equipment life

- Eliminate missed grease points

- Improve performance in cold weather

LubeMinder + NLGI #1 grease = the perfect winter-proof lubrication solution.

While NLGI #2 grease remains the go-to for many standard applications, it may not be the best choice in colder temperatures. Switching to NLGI #1 grease, especially when used with a LubeMinder Automatic Grease System, can dramatically improve lubrication reliability, equipment protection, and operational efficiency.