4 min read

The Importance of Lubricants in Food Processing Machines

LubeMinder Team

:

Oct 16, 2025 6:00:00 AM

It’s hard to repair your reputation after a food recall – headlines about contaminated food are hard to forget. That’s why it’s vital to get the food production right the first time.

When working in food processing facilities, one surefire way to ensure safe and hygienic food production is to protect your equipment. While there are many elements to proper maintenance, one of the most important factors to start with is the lubricants in these food processing machines. Proper lubrication can help facilities avoid costly shutdowns and product recalls.

Below, we’ll explain why lubrication matters in food processing machines, discuss regulatory compliance, and describe types of lubricants and conveyors used in the food industry. Then, we’ll talk about the benefits of an automatic lubrication system for food processing facilities.

Why Lubrication Matters in Food Processing Machines

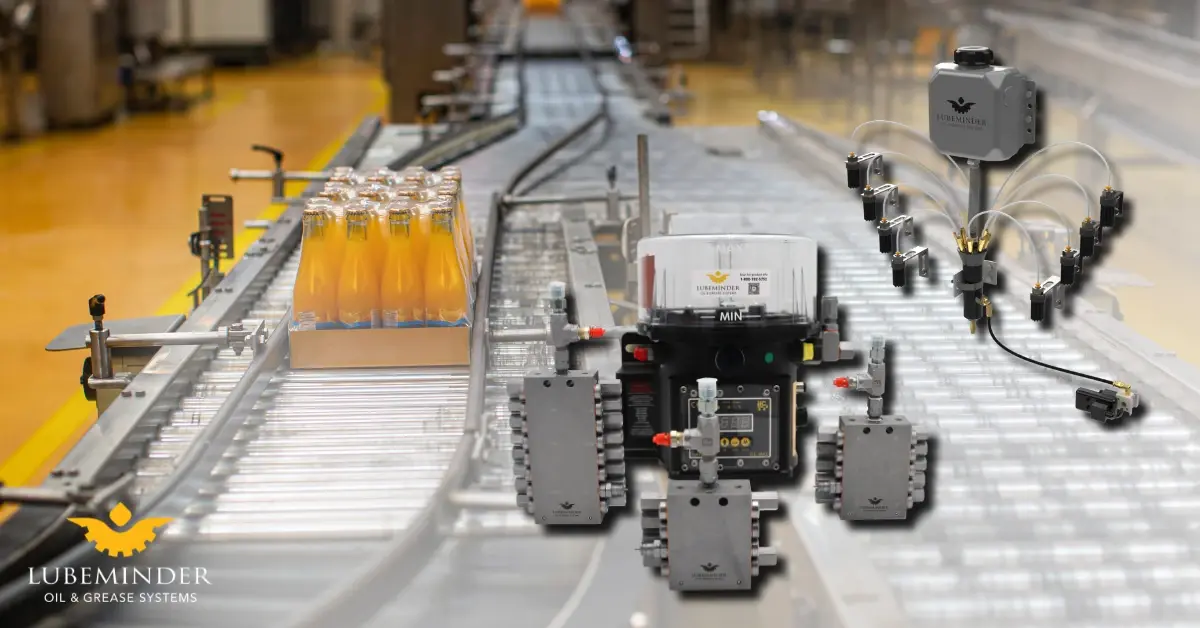

Food conveying systems ensure efficient and hygienic transport of products from start to finish. As with any other conveyor belt system, constant lubrication is a must. Challenges can arise when under-lubricated bushings, bearings, and chains experience excessive wear and tear. Improper lubrication can lead to equipment failures and halts in production. Conveyor belt lubrication systems deliver precise lubrication to avoid these issues.

Regulatory Compliance and Safety in Food Conveying Systems

The Food and Drug Administration (FDA) and the National Sanitation Foundation (NSF) collaborate to regulate food safety, protecting the public’s health through various regulations and certifications, including the industry standards around food processing and packaging. These regulations ensure proper food-grade lubricants and hygienic conveyor designs are used in food processing facilities that reduce human contact and avoid contamination.

By following these practices, manufacturers ensure product quality, uphold FDA compliance, use NSF-approved lubricants, protect their brand’s reputation, and – most importantly – public safety.

Let’s discuss the two main elements of the food safety compliance standards set by the FDA and NSF – food-grade lubricants and hygienic conveyor designs.

Food-Grade Lubricants

Anytime a machine is used for food production, food-grade lubricants must be used. Using the wrong type of lubricant in food production may not only be harmful to the machine, but also to the consumer. In some cases, incorrect lubrication can lead to contamination or even product recalls.

There are three tiers of food-grade lubricants regulated by the NSF:

- H1 lubricants: These are used in food processing machines where there is a chance of contact with food products.

- H2 lubricants: These are used on closed parts of the machine when there is no chance the food will come in contact with the lubricant.

- H3 lubricants: H3 lubricants are used for preventing rust and cleaning equipment. These are allowed to have direct contact with food. However, the equipment must be cleaned after use with H3 lubricants after resuming production.

Hygienic Conveyor Designs

Conveyors are a vital part of the food processing production, moving food from point A to point B, with as little human contact as possible. There are various types of food handling conveyors available, depending on the application and type of food. The most common types of conveyors include:

- Belt conveyors: These are the most widely used type of conveyor system in the food processing industry. Belt conveyors use a continuous belt, made from fabric or rubber, that moves over rollers to transport the food.

- Screw conveyors: These conveyors can operate at various angles, utilizing a rotating helical screw that moves food through a long tube.

- Bucket elevators: These vertical conveyors use buckets attached to a belt or chain to transport materials, often granular products such as grains or sugar.

- Pneumatic conveyors: These utilize air pressure to transport food materials, such as powders, through pipes or tubes.

- Roller conveyors: As the name suggests, these use rollers fixed to a frame to carry food products along the food processing line. Roller conveyors are ideal for heavy products and are commonly used in food packaging facilities.

Additional Factors to Consider When Choosing Your Progressive Distributor Block

In addition to the must-haves, there are a few other considerations when selecting your distributor block for your oil and grease system. These include:

- Maintenance and monitoring capabilities: Do you want a progressive block that allows for easy inspection, maintenance, and performance tracking? These can help improve production efficiency and extend the lifespan of your equipment.

- Cost and life cycle considerations: What is your budget? Will you be able to keep up with maintenance checks? This helps with the durability and longevity of your distributor block.

- Type of lubrication system: As you research distributor progressive blocks, consider how your current lubrication system functions. Is your system manual or automated? This will influence which blocks will work with your current system.

Benefits of Automated Conveyor Lubrication Systems in Food Production

Lubrication is vital for keeping machinery running at its best. Automated conveyor lubrication systems take out the guesswork. When an oil system is installed directly into your equipment, the costs of maintenance decrease. These automated systems offer many other advantages, including:

- Consistent lubrication: Automated systems deliver precise amounts of lubrication at regular intervals, ensuring bearings, chains, and sprockets are properly maintained.

- Limited contamination: By utilizing equipment that automates lubrication maintenance, the need for human interaction in the food manufacturing process is minimized, which helps reduce the risk of foreign material contaminating the products.

- Extended service intervals: With automated lubrication systems, you can lower your maintenance requirements and expenses.

- Minimized production disruption: By avoiding lubrication-related breakdowns, unexpected downtime occurs less frequently with fewer halts in production.

Benefits of Building a Customized Food Conveying System

Adding an automated lubrication system to your existing conveyor can certainly improve production efficiency and hygiene. However, designing your food production conveyor with a custom lubrication system at the start takes the benefits even further. By building these lubrication systems into the foundation of your equipment, you establish a system designed for long-term efficiency, hygiene, and reliability.

Custom lubrication systems can be tailored to the unique needs of your production environment. These systems support a more hygienic conveyor design while ensuring precise placement of food-grade lubricants on a set schedule to critical components such as bearings, chains, and sprockets. This reduces the need for manual intervention, lowering the risk of contamination, resulting in a cleaner, safer, and more reliable food conveyor production line.

Lubrication Safeguards More Than Just Food-Processing Machines

The importance of lubricants in food processing machines goes beyond maintaining equipment. It also plays a vital role in keeping consumers safe, preventing contamination, and following industry regulations during production.

Make lubrication systems a priority in your food processing equipment. It’s an investment in safety, compliance, and efficiency for your operation. Discover how our collection of automatic lubrication systems can keep your machines running at their best.