DIAMONDBACK: The Hydraulic Hose Sleeve Protection Solution

Commercial-grade hydraulic hose performance has a direct impact on job success. A pinhole leak or other issues with a hydraulic hose can mean extensive downtime and even risk of injury or death for the workers on-site. Extending the life of your hydraulic hoses by investing in a Diamondback protective hose sleeve means less downtime and greater productivity.

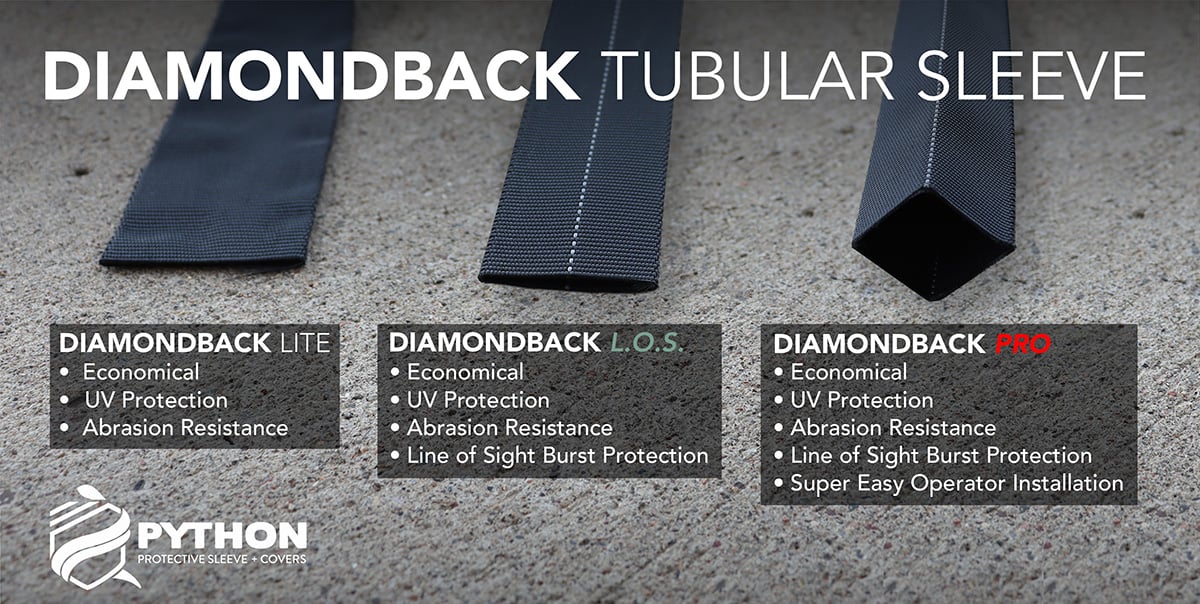

The Diamondback L.O.S. and Diamondback Pro tubular hose sleeves provide the perfect solution for extending the lifespan of hydraulic hoses by offering protection from wear and tear while also being easy to install. Both are essential for hydraulic hose safety. The Diamondback Lite tubular hose sleeve also offers protection from abrasion and UV degradation and is the economical version of the other two hose sleeve solutions.

CHOOSE YOUR DIAMONDBACK TUBULAR HOSE SLEEVE SOLUTIONS

DIAMONDBACK Line of Sight sleeve

PIN HOLE, BURST PROTECTION, & ABRASION PROTECTION

The Diamondback Tubular Sleeve offers dual uses by providing line-of-sight operator protection from hydraulic hose failure and abrasion resistance. Often used in construction applications, Diamondback is made from a proprietary engineered fiber woven tightly and heat-treated, which shrinks the sleeve to the finished dimension. The Diamondback Sleeve meets the EU Machinery Directive 2006/42/EC as well as the NSW "Guideline for Fluid Power System Safety at Mines."

- Tested over 1.7 million abrasion cycles (ISO 6945)

- Meets "Line of Sight" operator protection specification EN982, EN414, EN ISO Regulation 3457:2008

- Pinhole protection tested to 4,000 PSI. Burst protection Tested to 12,000 PSI

- Temperature tested to 200°F continuous, 350°F intermittent

- Cut to length, 50% less bulky than Cordura

- Tight, smooth surface contains oil spillage from pin hole leaks

- Mine Safety and Health Administration (MSHA) approved IC-289/01

- Meets conductivity standard ISO 8031

- Unmatched UV Protection

- Sleeve dispensers available

DIAMONDBACK PRO

PIN HOLE, BURST PROTECTION, ABRASION PROTECTION & EASE OF INSTALLATION

The Diamondback PRO Sleeve provides the easiest installation benefits in the market. Operators are saving up to 80% on installation costs when compared to standard nylon sleeves.

How? Its proprietary material and extra tight weave keeps the sleeve in a diamond shape during installation - allowing the hose to easily slide through.

- Reduces sleeve installation by up to 80%

- Tested over 1.7 million abrasion cycles (ISO 6945)

- Meets "Line of Sight" operator protection specification EN982, EN414, EN ISO Regulation 3457:2008

- Pinhole protection tested to 4,000 PSI. Burst protection Tested to 12,000 PSI

- Temperature tested to 200°F continuous, 350°F intermittent

- Cut to length, 50% less bulky than Cordura

- Tight, smooth surface contains oil spillage from pin hole leaks

- Mine Safety and Health Administration (MSHA) approved IC-289/01

- Meets conductivity standard ISO 8031

- Unmatched UV Protection

- Sleeve dispensers available

DIAMONDBACK Lite

UV Protection & ABRASION Resistance

The Diamondback Lite Tubular Sleeve offers protection from abrasion and UV degradation. Often used in agriculture, construction, and mobile equipment applications, Diamondback Lite is made from a proprietary engineered fiber woven tightly and heat-treated, which shrinks the sleeve to the finished dimension.

- Tested over 40,000 abrasion cycles (ISO 6945)

- Temperature tested to 200°F continuous, 350°F intermittent

- Easy install; Cut to length with a scissors

- Mine Safety and Health Administration (MSHA) approved

- Meets conductivity standard ISO 8031

- Unmatched UV Protection

- Sleeve dispensers available

WHAT'S THE DIFFERENCE?

product videos