Custom & OEM Commercial Sewing

Fabricating | Converting | Custom Parts

Our Quality

As a division of Suburban Manufacturing Group, Python Protective Sleeve + Covers is industry certified and follows LEAN manufacturing to ensure best practices for quality, reliability and delivery.

.jpg?width=183&height=143&name=Qualty_and_Testing_ISO_Certified_Python_Covers%20(1).jpg)

ISO Certified

Our ISO 9001:2015 certification ensures trust and integrity in everything we touch, see and do. In a competitive market that becomes cheaper, Python offers quality and reliability.

Quality Checks

Our sewing technicians perform first article and final quality checks. During production, job travelers are used to check stitching, seams, edges, etc. as the product moves down the line.

Premium Materials

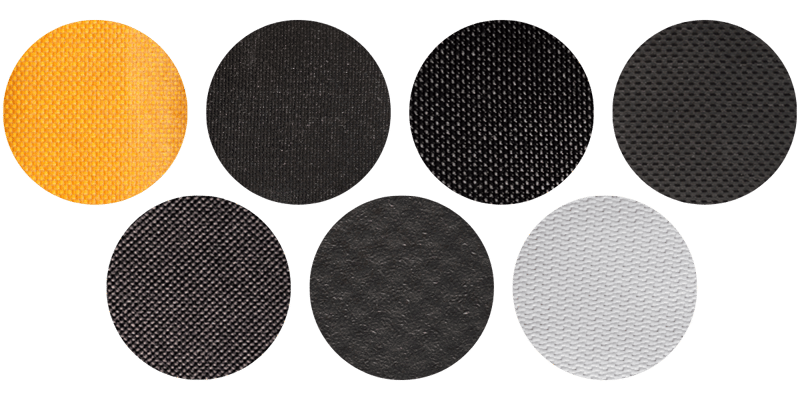

Every new material to enter our building is abrasion tested. Allowing our engineers to recommend the right solutions for our clients projects.

Turnkey Solutions

![]() High Temp Covers

High Temp Covers

![]() Electrical Sleeving

Electrical Sleeving

![]() Energy Chain Covers

Energy Chain Covers

![]() Industrial Straps & Hose Guides

Industrial Straps & Hose Guides

![]() DEF Tank Covers & more!

DEF Tank Covers & more!

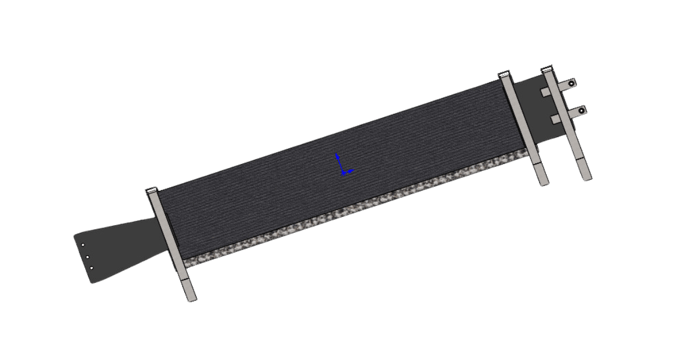

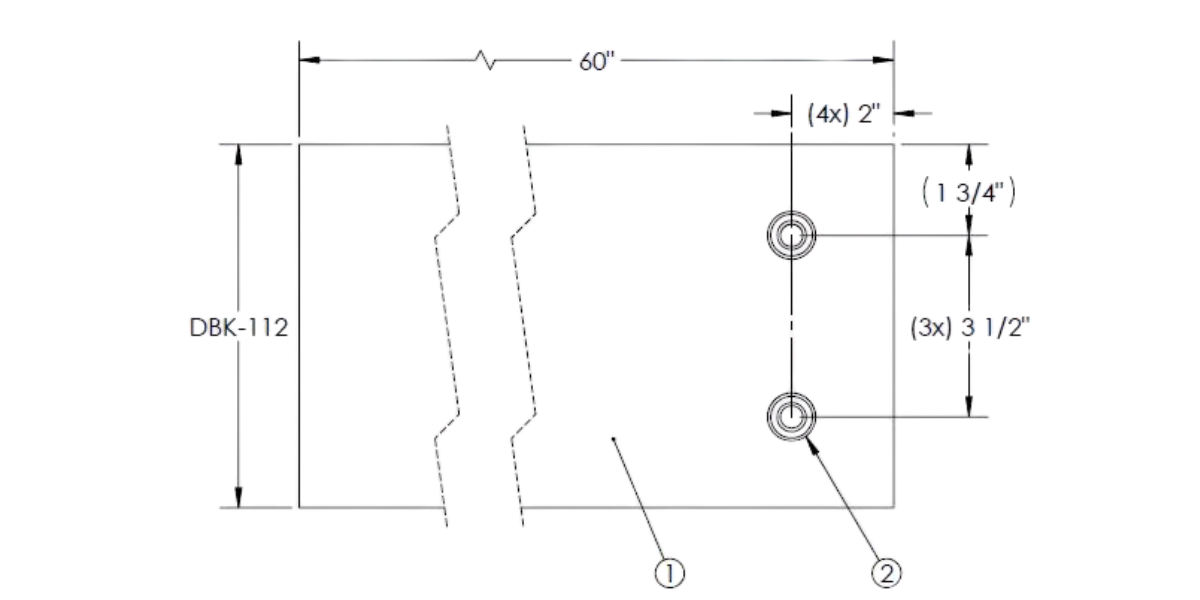

CUSTOM CAPABILITIES

Build the perfect part for your real-world application and receive design support from our in-house team of experts. We offer a variety of materials and an array of colors so we can tailor textiles to your needs, and bring your solution to life. Our team of experienced engineers ensure your custom solution is made with exceptional quality, exactly how you like it.

Custom Manufacturing & Engineering

Ideation to production

![]() Ideation and design with our experienced in-house engineering team.

Ideation and design with our experienced in-house engineering team.

![]() Engineered prototypes are streamlined and sent to the customer for approval.

Engineered prototypes are streamlined and sent to the customer for approval.

![]() LEAN manufacturing process guides our production team to produce parts quickly.

LEAN manufacturing process guides our production team to produce parts quickly.

![]() Quality inspections on first and last articles using our ISO 9001:20115 standards.

Quality inspections on first and last articles using our ISO 9001:20115 standards.

Fabricating & Sewing

Python Covers is a vertically integrated, custom textile manufacturer of materials used in industrial and mobile hydraulic applications. In addition to our extensive material, we also offer fabricating and converting services.

-

What is custom fabricating and converting?

Custom materials fabricating and converting is a process where the original material is modified into a specific format to satisfy the need of the manufacturing process.

-

Common converting techniques

- Hot & Cold Knife Straight Cutting

- Rotary Die Cutting

- Webbing

- Packaging and Kit Assembly

- Grommet Setting

- Custom Straps

-

State-of-the-art

In order to provide the highest quality and flexibility, we invested in modern state-of-the-art machinery and engineering processes to offer you exactly what you need for your application.

Development & Testing

Product development and testing is an important part of the custom manufacturing process - and here at Python our goal is to have everything we create stand the test of time. In each step of development, our expert engineers test the products to ensure the cover is snug, the loop is hooked in, and it is ready to go. Our textile services are vast, just as the industries we design products for.

-

OEM Industrial Services

- Concept Design

- CAD Modeling

- Prototyping

- Sample Market

- Product Testing

- Mass Production

- Graphic Art Printing

- Private Label Packaging

- Concept Design

-

Product Development OEM Industries

- Agriculture

- Construction

- Spray Foam

- Military Defense

- Power Sports

- Manufacturing

- & more!

-

New Product Prototyping and Testing

- Ultraviolet Exposure

- Abrasion Testing

- Hot/Cold Temperature Exposure

- Chemical Testing

- Application-Fitting

- Burst Testing

- Tensile Strength Testing

- Ultraviolet Exposure

Industrial sewing

Our engineers create configurable solutions for a variety of industries.

Custom textile solutions at Python

-

Why Python Covers?

We never shy away from a custom textile challenge. We have decades of experience working with a variety of materials and applications to solve any inquiry that comes our way. Our network of vendors allows us to source new materials specific to our customers needs to give you the perfect solution time and time again.

-

ISO Certified

Our ISO 9001:2015 certification ensures trust and integrity in everything we touch, see and do. In a competitive market that becomes cheaper, Python offers quality and reliability.