3 min read

Comparing Float, Pneumatic, and Electronic Drains

Tsunami Team

:

Apr 14, 2021 12:00:00 AM

Which type of drain is best for your compressed air system? Where is the drain being used: on your compressor tank, at the bottom of a drip leg in your air piping, or on your filter? Knowing the different types and how they work is a great start in designing the best air system for your application.

Read below to learn more about the types of drains and how they work:

- VIDEO: Automatic Drains for Air Compressors

- What is a Float Drain?

- What is a Pneumatic Drain?

- What is a Electronic Drain Valve (EDV)?

Although there are various ways to remove water from compressors, drip legs and air filters, the three main types are float drains, pneumatic drains and float drains. The two similarities of these drains are:

- Each is designed to remove liquids (duh)

- All are automatic. No mandatory draining necessary!

The video below highlights the three drain categories available for Tsunami Air Filters, keep reading to understand more details and how they work.

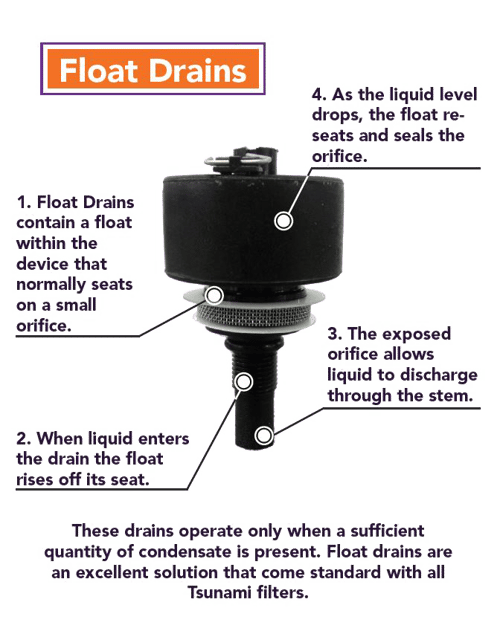

What is a Float Drain?

Float drains contain a float within the device that normally seats on a small orifice. When liquid enters the drain the float rises off its seat, exposing the orifice and allowing liquid to discharge through the stem. As the liquid level drops, the float re-seats and seals the orifice. These drains operate only when a sufficient quantity of condensate is present.

As shown in the image above, here's how a float drain works:

- There is a plastic "float" that sits atop an orifice

- As liquid enters the drain, the float rises off it's seat

- When the float reaches is max height, the exposed orifice allows liquid to discharge through the stem

- As the liquid level drops, the float re-seats and seals the orifice

- The process repeats itself automatically, for eternity!

When being used as your primary drain on your compressor, the drains usually have a manual override which allows for drainage of the system on demand or during cleaning.

Most float-operated drain valves leave a small amount of condensate in the reservoir when discharging; this prevents the loss of valuable compressed air. However, this small amount of moisture can still degrade your tank.

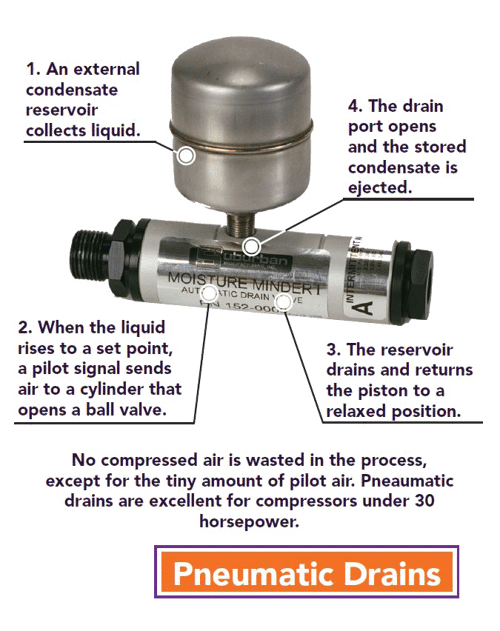

What is a Pneumatic Drain?

Pneumatic drains are simple and robust.They rely on a pneumatic pilot signal to operate and use a ball valve to eject the moisture from the air system.

As mentioned in the video, the pneumatic drain has a simple operation:

- An external (or internal) condensate reservoir collects the liquid.

- When the liquid rises to a set point, a mechanical pilot signal sends air to a cylinder that opens a ball valve.

- The drain port opens and the stored condensate is ejected (drained).

- The reservoir drains and returns the piston to a relaxed position.

The ball check closes preventing zero pressure loss in the system. The drain port opens and the stored condensate is ejected. No compressed air is wasted in the process, except for the tiny amount of pilot air.

The drain pictured above is for compressors, dryers and drip legs. The drain pictured below is for our Tsunami Filter line. The threaded design allows for quick install and replacement.

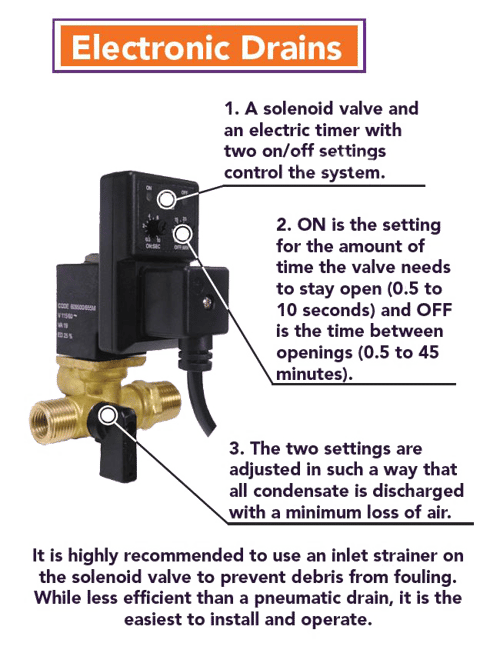

What is an Electronic Drain Valve (EDV)?

Electronic drains require electricity and, unlike the other drain models, can be adjusted for frequency and duration of the discharge time.

Electronic drains incorporate a solenoid valve and an electric timer with two on/off settings. ON is the setting for the amount of time the valve needs to stay open (0.5 to 10 seconds) and OFF is the time between openings (0.5 to 45 minutes).

The two settings need to be adjusted to the size of the compressed air system in such a way that all condensate is discharged with a minimum loss of air.

The optimum ON time is between .5 to 1 second; when ON for a longer period, air begins to push the water aside to escape; making the efficiency of the drain pulse less effective. Setting the OFF time is critical to assure your drain cycle rate actuates often enough to remove the water. This can be fine tuned based on the system and the time of year.

As atmospheric conditions change, so does the impact on moisture levels getting into your air system. It is also highly recommended to use an inlet strainer on the solenoid valve to prevent debris from fouling.

Which drain is right for you? Contact Tsunami Compressed Air Solutions and ask to speak with one of our experts!

(Editor’s note: This blog was originally published in April 2021 and was updated in November 2023.)