AIR Contamination and Paint finishes

Do any of these problems in your paint seem familiar?

-

Low gloss

-

Hazing

-

Cratering

-

Dye back

-

Fisheye

Did you know?

Over half of all paint finish issues can be attributed to the quality of your compressed air.

Compressed air that contains dirt, water, and other contaminants is destructive to professional paint jobs and pro finishing. Using contaminated air in a particular application causes poor results instead of the high-quality finishes that painters, and the auto body industry, have come to expect. Taking the necessary steps to provide ultimate clean, dry air eliminates the risk of producing a poor paint job for high-paying customers.

COMPRESSED AIR FOR AUTOMOTIVE APPLICATIONS

When you upgrade to a Tsunami solution, you take the guesswork out of compressed air. Our compressed air dryers and air filters offer a variety of CFMs to compliment your system and increase efficiency. They also:

-

Remove humidity

-

Eliminate contaminants

-

Get rid of oils & oil vapor

-

Provide consistent results

Improve your company's operations with an air system to provide ultra-dry air for today's complex waterborne paints.

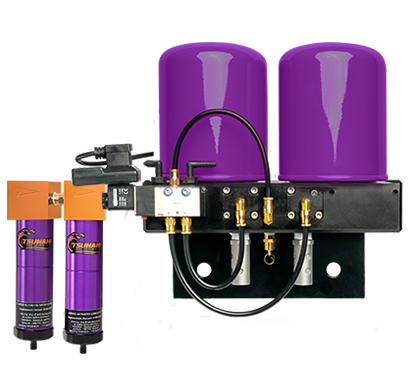

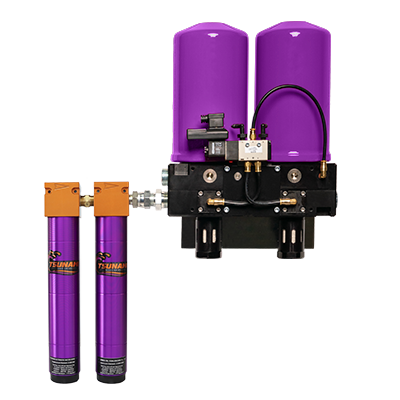

Desiccant Air Dryer for Automotive

The Tsunami CORE dryer is the ideal solution for intermittent, low pressure point-of-use applications. With a media life that lasts up to 25% longer than competing brands and super easy maintenance, this addition to your system will lower costs and increase operation efficiency while improving the quality of your auto body finishes.

Air Filters for Perfect Paint Applications

For flawless automotive finishes, air filtration is non-negotiable. By eliminating liquids, oils, and particulates from your compressed air, you'll prevent airline corrosion and ultimately ensure the best possible paint results while minimizing costly repairs and downtime.

Aftercooler for Auto Body

Ensure pristine paint finishes in your body shop with our versatile, wall-mount aftercooler. Cooling the compressed air significantly reduces moisture contamination, optimizing the performance of downstream air dryers and extending the life of your critical paint application equipment, minimizing costly downtime.

Respiratory Protection for Body Shops

When you need Grade D breathing air in your facilities and job sites, breathing air panels are the optimal solution. The complete system includes a 3-stage filtration system that effectively removes harmful particles, moisture, and other contaminants before entering your airways, a carbon monoxide alarm, and a CO monitor calibrator with Autocal®.

REGENERATIVE & Desiccant AIR DRYERS FOR PAINT, BODY, & EQUIPMENT NEEDS

Desiccant pots and refrigerant dryers offer notable moisture removal capabilities. However, their performance can be influenced by factors such as high air flow rates or extended operational periods. For instance, the desiccant material in a pot has a finite capacity for moisture absorption and will eventually require replacement once saturated. Similarly, the effectiveness of refrigerant dryers can be impacted by rapid air flow, which may limit the system's ability to adequately cool the air to its dew point for optimal moisture condensation.

Tsunami regenerative dryers use multiple canisters of desiccant that regenerate using sweep air. This means clean, dry air for any environment or application.

-1.png?width=2206&height=1200&name=new%20web%20photo%20(web)-1.png)

.png?width=500&height=500&name=23224_SMG_Tsunami_AirDryer_pure5-T%20(WEB).png)

-1.png?width=500&height=500&name=23224_SuburbanManufacturing_Tsunami_PURE-5T_with-stand%20NEW%20COLORS%20(web)-1.png)