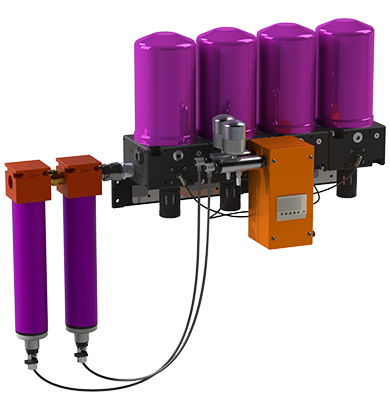

INSTRUMENT AIR DRYERS FOR OIL & GAS

INVEST IN RELIABILITY WITH OUR PREMIUM ENERGY-EFFICIENT COMPRESSED AIR SYSTEMS.

As compressed air demand increases in oil and gas operations, producers need to rely on clean, dry air to ensure smooth operations without costly downtime due to freeze-ups and repairs. With a compressed air drying system from Tsunami, businesses can focus on what matters most without the worries of a clean air supply.

We'll explore the benefits of having a reliable pneumatic control system for compressor stations to improve the efficiency, quality, and safety of your oil and gas facilities.

COMPRESSED AIR: THE 4TH UTILITY IN OIL & GAS OPERATIONS

In the oil and gas industry, compressed air is regarded as the "fourth utility" behind water, electricity, and gas itself. Compressed air is valuable in production from start to finish and everything in-between. It plays an instrumental role in:

Petroleum refining is a process where petroleum is compressed with an air compressor before it's transported into a pipeline. This process requires an air dryer because it needs quick, strong air flow to compress the petroleum for transportation.

In the manufacturing of ammonia, methanol, urea, and other petrol chemicals, petrochemical synthesis is when compressed air pressurizes gas before the chemicals get sent to the next step of the process. In the manufacturing of gas, this is a required step to deem chemicals usable.

Gas re-injection is a process used in the oil fields for maintaining reservoir pressures for safe operations. A series of air compressors can be used to preserve the optimal pressure of reservoirs.

The pressure of the reservoir gradually decreases overtime while oils and gases are pushed throughout the pipeline. Due to the natural decrease in reservoir pressure, compressors are needed to maintain or boost gas flow into the pipeline system to maintain consistent momentum.

Clean, dry air is critical in this industry, especially for the preservation of equipment used throughout the day to complete vital oil and gas processes. By having a reliable air dryer system, each droplet of moisture and water will be pulled away so only the driest air will be applied to each stage it's required for, and increase the quality in stages where clean air would vastly improve the finished product.

By having clean, dry, instrument air you can:

FOCUS ON UPTIME

Having consistent, dry air allows you to focus on other ways you can improve or further streamline the oil and gas process, get ahead on other parts you may have fallen behind on, and get a head-start on other stages. With such an intensive process, having a reliable air system will be one less thing to worry about day-to-day and focus on the next big project.

DECREASE DOWNTIME

The cost of downtime is extremely high; especially in the oil and gas industry. Each minute is precious with the amount of deadlines and quotas that need to be met to ensure the product gets to where it needs to.

For example, when pneumatic valves freeze up due to a lack of dry air, everything gets stalled until the valves are replaced. This affects deadlines, volume, and adds on an additional expense. With an effective air dryer, these kinds of detrimental downtime can be completely avoided to increase profit.

REDUCE MAINTENANCE COSTS WITH ENERGY EFFICIENCY

Having clean air aids in working against the conditions of the surrounding environment known to harm machinery. Dry, clean instrument air ensures pneumatic valves actuate when they need to in order to keep the process on schedule. Instrument air also helps maintain pneumatic control systems so they'll require less maintenance, less often. The oil and gas industry operates in heavily contaminated areas, so by having instrument air to keep equipment clear, you can rest assured knowing your equipment is operating as efficiently and effectively as possible.

QUAD O: THE FUTURE OF CLEAN AIR

Methane gas is known as the most harmful pollutant, often dubbed as a "super pollutant" due to the volume of carbon dioxide it releases. Approximately one third of methane gas is responsible for negative environmental impacts. Oil and gas operations are the cause of a vast amount of methane gases known to harm the environment, harm the o-zone layer, and lower breathing air quality.

On December 2, 2023 the EPA issued a final ruling for oil and gas operations in an effort to reduce methane emissions and other harmful pollution. This ruling means new and currently running oil and gas operations are required to make the necessary changes to ensure they are following the new guidelines. By reducing the amount of methane in the air, the environment will have a better chance at recovering.

Compressors located at well sites remain unaffected, however compressors located at the newly defined “centralized production facility” are affected. In addition, new dry seal centrifugal compressors—a previously unaddressed source—are expected to meet the new Quad O-B requirements.

Reciprocating compressors are required to maintain emissions at or below two standard cubic feet per minute (scfm) per cylinder. Dry seal centrifugal compressors are required to maintain flow rates equal to or less than 10 scfm per seal and wet seal centrifugal compressors must maintain flow rates equal to or less than three scfm per seal. Alternatively, emissions may be controlled to achieve a 95% reduction.

Instrument Air for Oil and Gas Regulations

As regulations are passed in an effort to protect workers and the environment, the need for clean instrument air is only increasing. Due to the variety of locations oil and gas operations take place, having clean air aids in working against the conditions of the surrounding environment known to harm machinery, but that's not all. The benefits of implementing instrument air in the oil and gas industry are:

- Increased Safety: As mentioned, by having clean air flowing through equipment and instruments decreases the possibilities of broken equipment; this reduces the chances of dangerous conditions.

- Better Reputation: By following Quad Zero regulations, your oil and gas refinery will pale better in comparison to those not following the guidelines and reap the benefits with ethical collaborators and possible environmental accolades.

- Reduce Environmental Impact: By reducing the environmental impact, you are improving life for field operators, yourself, and the future of the planet.

Tsunami Compressed Air Solutions has been setting the industry standard for over 40 years with top-of-the-line air dryers and pneumatic systems. Not to mention, our customer support is second to none; with our domestically located headquarters , we have local experts standing by ready to answer the phone. Download our free resource guide below to learn how our systems can deliver the high-quality air your operations need while maintaining optimal efficiency and minimal servicing.

Download the guide below to learn how our systems will:

Prevent freeze-ups and downtime

require minimal servicing

Maintain optimal efficiency