“The desiccant pots you never have to change.” -a very wise person

Regenerative Air Dryers combine the latest in simplicity and innovation. Two towers attached to an anodized housing use a pilot signal to cycle the air between towers during operation. It’s like replacing the desiccant every two minutes. Get the dry air you want, without the hassles you hate, by investing in a compressed air regenerative dryer.

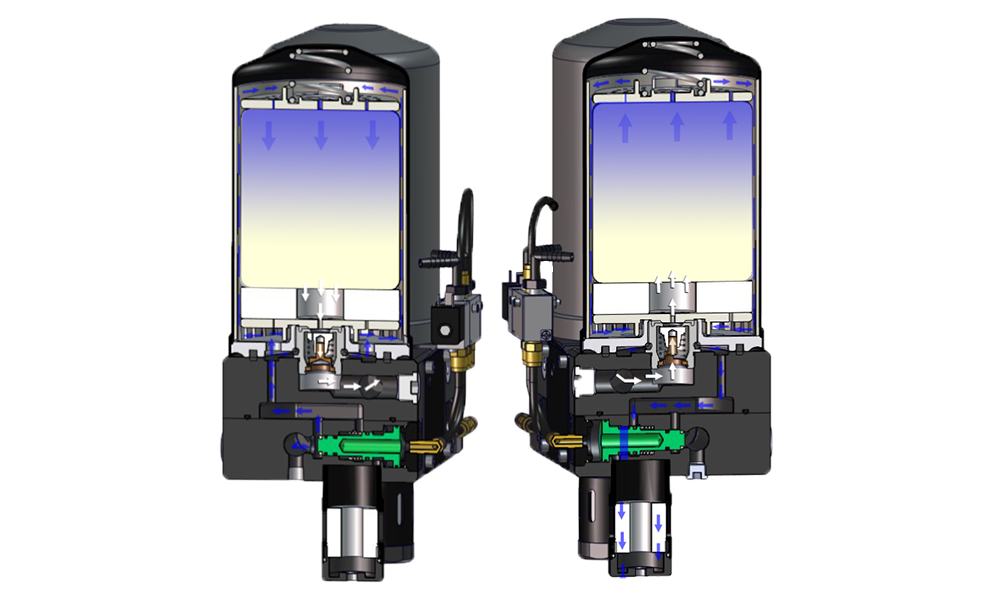

How a Heatless Desiccant Regenerative Dryer Works:

Regenerative air dryers operate in two cycles: the drying process and the regeneration process. Both occurring simultaneously, the twin-desiccant towers work together with each tower undergoing one of the processes. While one tower is drying the air, the other tower is borrowing “sweep” air to dry or regenerate the desiccant material.

The Drying Process

- Pre-filtered air enters the dryer and is channeled through the desiccant tower(s).

- Wet air passes through the tower(s) where desiccant draws water vapor in while under pressure.

- After flowing through the desiccant, the now dry air is sent downstream.

- After two minutes, the control timer sends out a pilot signal shifting the internal piston. When the piston shifts, air is redirected from this tower(s) to the opposite.

The Regeneration Process

- A small amount of air from the dry outlet on the opposite tower(s) percolates up through the regeneration orifice and back through the desiccant filled tower(s).

- The desiccant is dried as the sweep air passes back through the media.

- With the use of this air, the tower(s) discharge water vapor through the mufflers located below the dryer manifolds.

- After 2 minutes, the control timer sends out a pilot signal shifting the internal piston. When the piston shifts flow is reversed and this tower(s) begins drying the air.

Benefits of Compressed Air Regenerative Dryers:

Regenerative desiccant dryers are both economical and effective commercial drying solutions. OEMs that require drying stations will be able to take advantage of the benefits of desiccant dryers including:

- Easy, low cost maintenance

- Dew points down to -40°F

- Low relative humidity down to .01% RH

- Perform well with high demand surge flows

- No Aftercooler required

- Tsunami Dryers include pre-filtration (water separator + oil coalescing filter)

- Economical models available

Regenerative Air Drying Systems from Tsunami Compressed Air Solutions are the ideal solution for users interested in the benefits listed above. To view Tsunami Dryers, click here!

%20WEB.png?width=400&height=400&name=23224_SMG_Tsunami_AirDryer_Pure10_21999-1010%20(new%20colors)%20WEB.png)