Air dryers use desiccant beads or cartridges to remove water vapor from an air stream; providing extremely dry air for critical applications and machinery. Understanding the different types of desiccant is crucial in selecting the right air dryer for your system.

What is Desiccant?

Desiccant is a type of beaded material that has the ability to attract and hold liquids and other gases. You’ve most likely seen desiccant being put to work in your shoe box, medication package, or any electronic (hint: it’s the mesh bag that says “DO NOT EAT”).

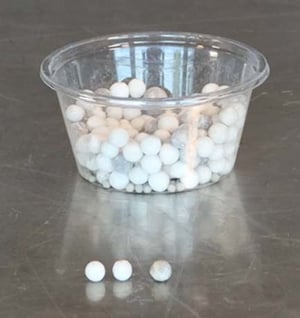

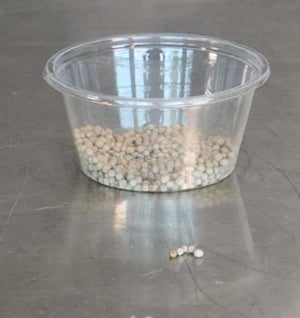

In an air dryer, desiccant beads are used to adsorb water vapor to provide dry air downstream. There are various types of desiccants that are used across many brands.

Desiccant Beads 101

The top three most common are:

- Silica Gel

- Activated Alumina

- Molecular Sieve

Not everyone is a desiccant dryer pro, so we’ve compiled what you need to know about all three types.

Silica Gel Desiccant Beads

Silica gel is most commonly used in packaging because of its ability to adsorb moisture quickly with little or no pressure. In an air system, it can offer excellent adsorption providing dew points down to -40°.

However, this ability to rapidly attract water vapor can be impacted when faced with liquid water. When completely saturated, the bead will crack into small fragments. These smaller fragments will migrate downstream in your air system.

This media migration (small fragments and dust) can do significant damage downstream, damage to your equipment, or the performance of your applications that do not have pre-filtration.

Activated Alumina Desiccant Beads

Activated Alumina is a porous form of aluminum oxide. Activated Alumina provides high adsorption, dew points down to -40°, and resists the breakdown that silica gel experiences when faced with liquid water or high saturation levels of water vapor.

However, Activated Alumina does “dust” when subjected to pressure swings and pulsations within a compressed air system.

Typically, being a larger bead, a well-performing system utilizing activated alumina will require larger vessels (more space) to obtain the same results as its smaller competitors.

Molecular Sieve Desiccant Beads

A molecular sieve is a small, sodium aluminosilicate bead. When used in an air dryer, molecular sieve can reach dew points as low as -100°F.

This media does not fracture when submerged in water or exposed to high levels of water vapor. Being a smaller bead with a very high surface, much less storage capacity is needed to dry the same volume of compressed as its counterparts.The cost of Molecular Sieve is often higher than Silica Gel or Activated Alumina but this cost can be justified through increased longevity and higher performance.

Choosing the Best Desiccant Air Dryer for Your Application

When choosing a drying solution for your industrial application, the options can seem overwhelming. Working with a professional to talk through your options is one of the most effective ways to ensure you’re getting the clean dry air you need.