How does an air lubricator work?

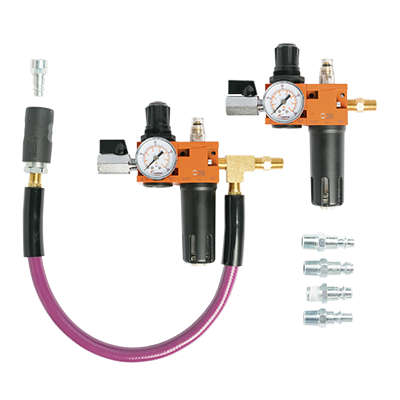

Drum pumps and agitators have moving parts within them that pull the chemical from the drum to be pushed downstream. These moving parts require a small amount of lubrication to prevent wear and tear on the system. By installing a Lubrication Kit at the point-of-use, the equipment will work better and last longer.

When air passes through the device, a needle valve drops small amounts of oil that becomes atomized. As the atomized oil hits the motor parts, it turns to liquid droplets, therefore lubricating the moving parts. drum pumps are air motors, piston, rapid cooling freezes from rapid expansion as air exists the piston.

- Avoid premature equipment failure from lack of lubrication

- Lubrication where it's needed, none where it's not

- Lube your pumps and mixer with one easy-to-install kit

- Regulator prevents over-pressurization

- Quick-connect fittings included

Sizing & Ordering Information

×

| Description | ITEM # | MSRP |

|---|---|---|

Air Lubrication Kit |

21999-1200 |

$538.00 |

Product Videos

3 min read

What is an Effective CFM for Your Air Compressor System?

Tsunami Team: Jan 5, 2026

Inefficient or under-calculated airflow can quickly become your production’s worst nightmare. When your system doesn’t...

4 min read

Cost per CFM of Compressed Air: Is Your System Efficient?

Tsunami Team: Dec 15, 2025

The cost of producing compressed air could be costing your business a lot of money. Even worse, you may not even know...

Contact

NEWSLETTER SIGN-UP

© 2026 Suburban Manufacturing