How does an air lubricator work?

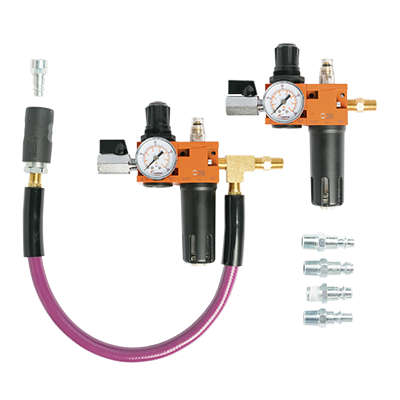

Drum pumps and agitators have moving parts within them that pull the chemical from the drum to be pushed downstream. These moving parts require a small amount of lubrication to prevent wear and tear on the system. By installing a Lubrication Kit at the point-of-use, the equipment will work better and last longer.

When air passes through the device, a needle valve drops small amounts of oil that becomes atomized. As the atomized oil hits the motor parts, it turns to liquid droplets, therefore lubricating the moving parts. drum pumps are air motors, piston, rapid cooling freezes from rapid expansion as air exists the piston.

- Avoid premature equipment failure from lack of lubrication

- Lubrication where it's needed, none where it's not

- Lube your pumps and mixer with one easy-to-install kit

- Regulator prevents over-pressurization

- Quick-connect fittings included

Sizing & Ordering Information

×

| Description | ITEM # | MSRP |

|---|---|---|

Air Lubrication Kit |

21999-1200 |

$511.00 |

Product Videos

2 min read

Tsunami Aftercooler - New Product Winter 2025

Mar 3, 2025 by Tsunami Team

Tsunami Compressed Air Solutions Announces New Aftercooler for Winter 2025 Has a faulty air dryer ever brought your...

3 min read

Benefits of Point-Of-Use For Compressed Air Dryers

Jan 20, 2025 by Tsunami Team

Compressed air systems play a vital role in countless industrial and commercial applications. However, moisture and...