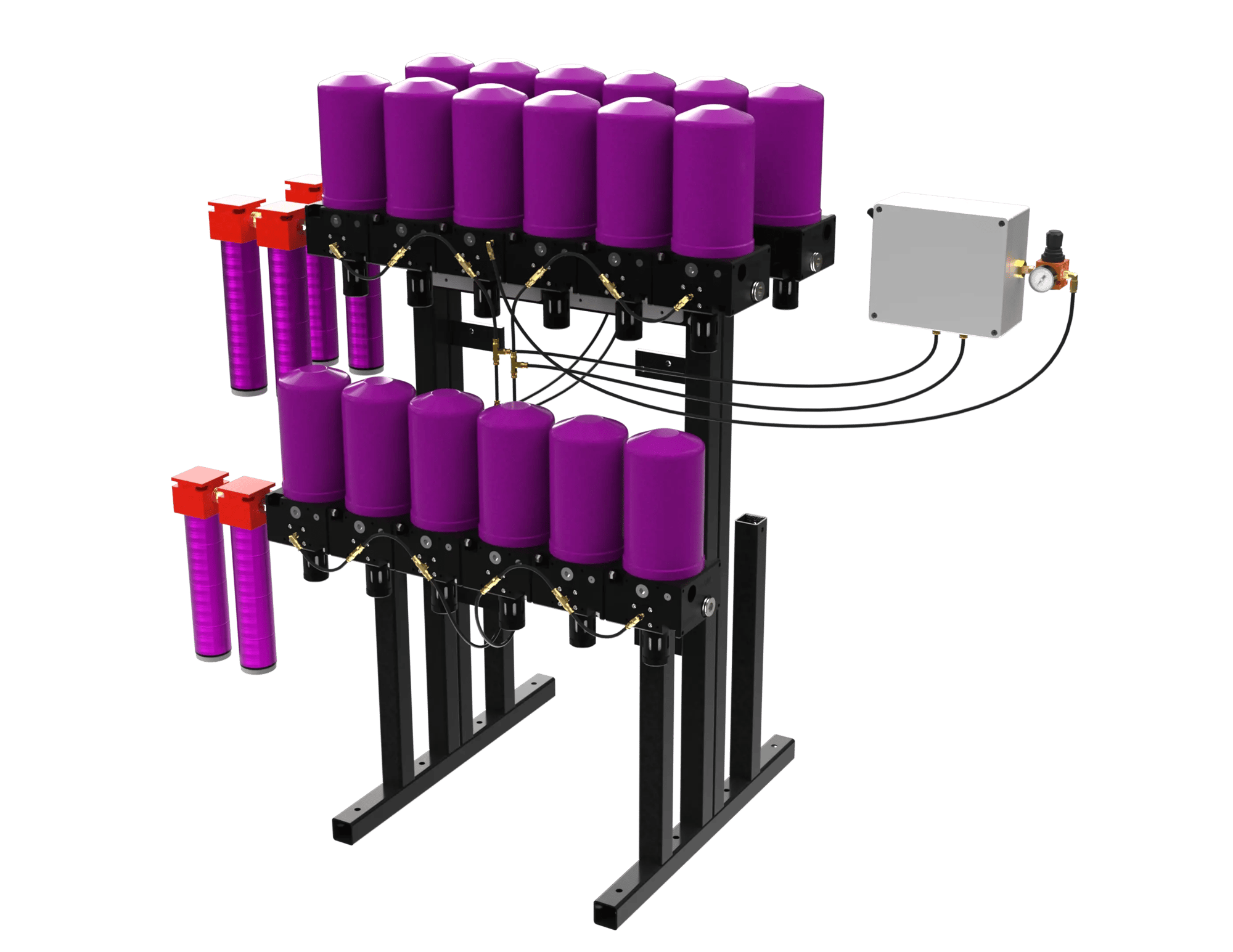

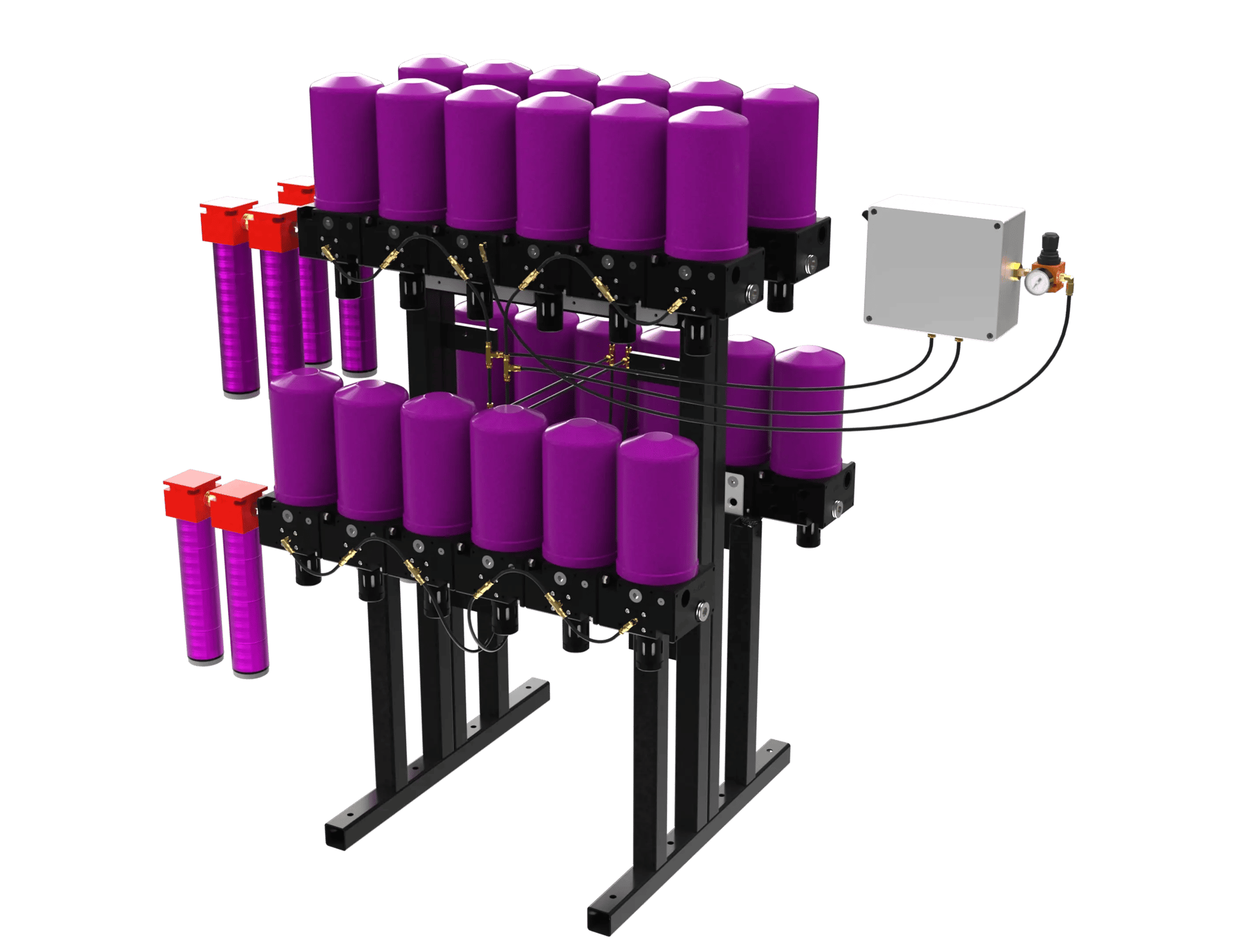

Pneumatic Air Dryers

Explosion-proof, gas-safe dryers

For C1D1 hazardous locations

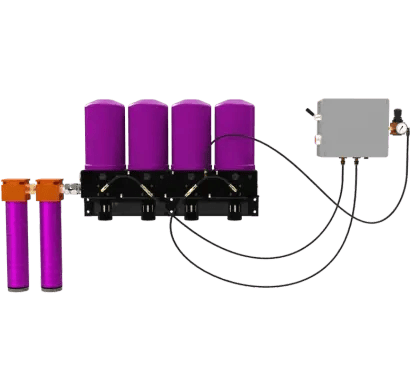

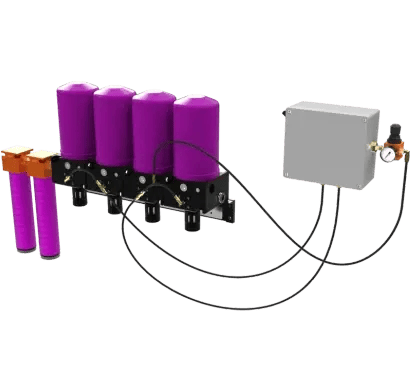

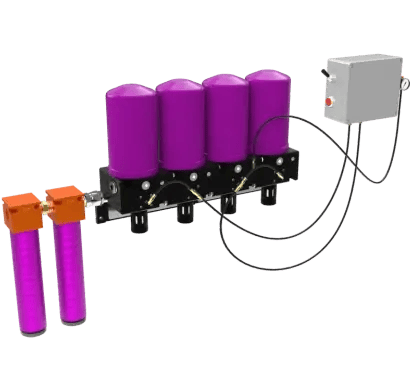

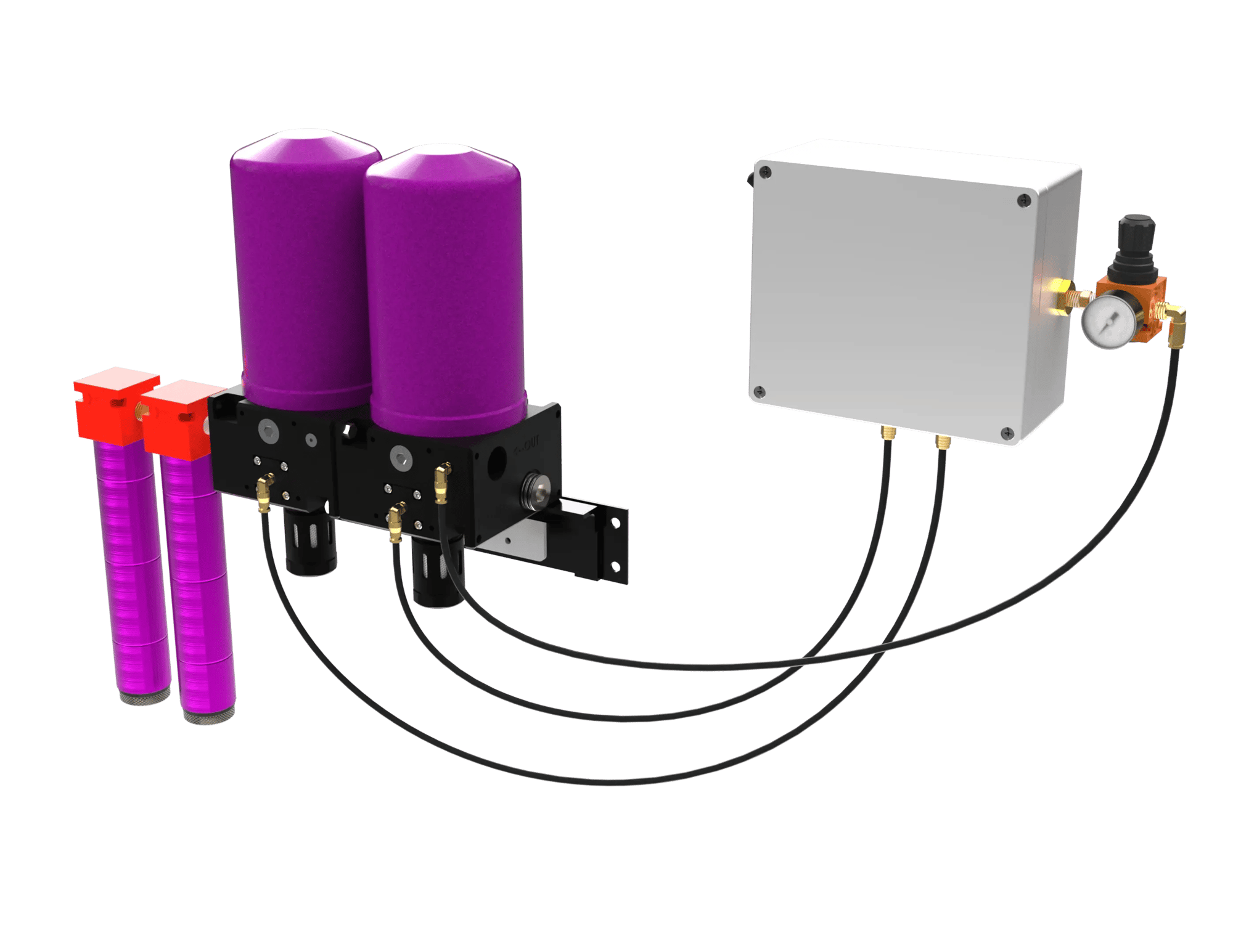

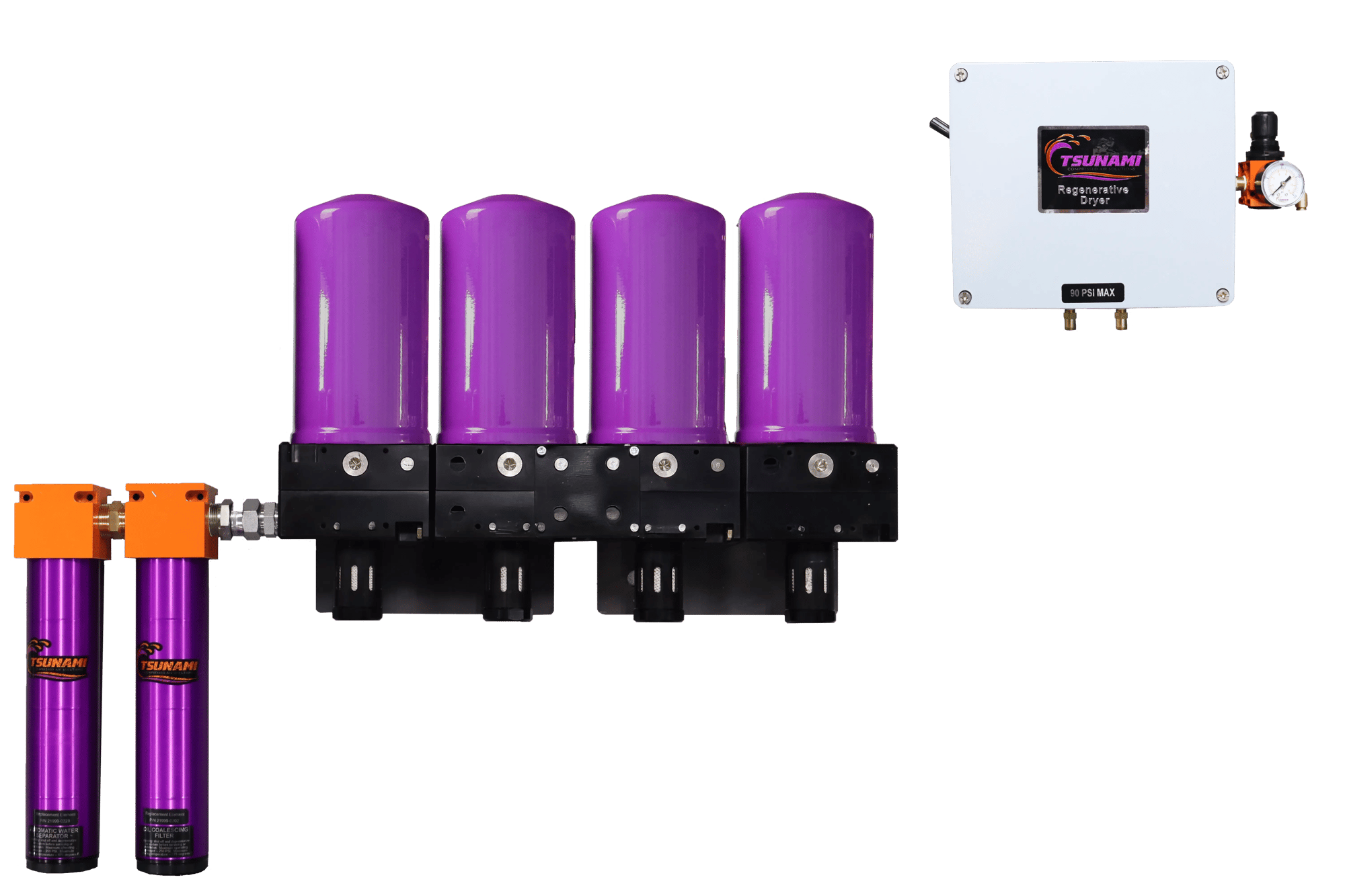

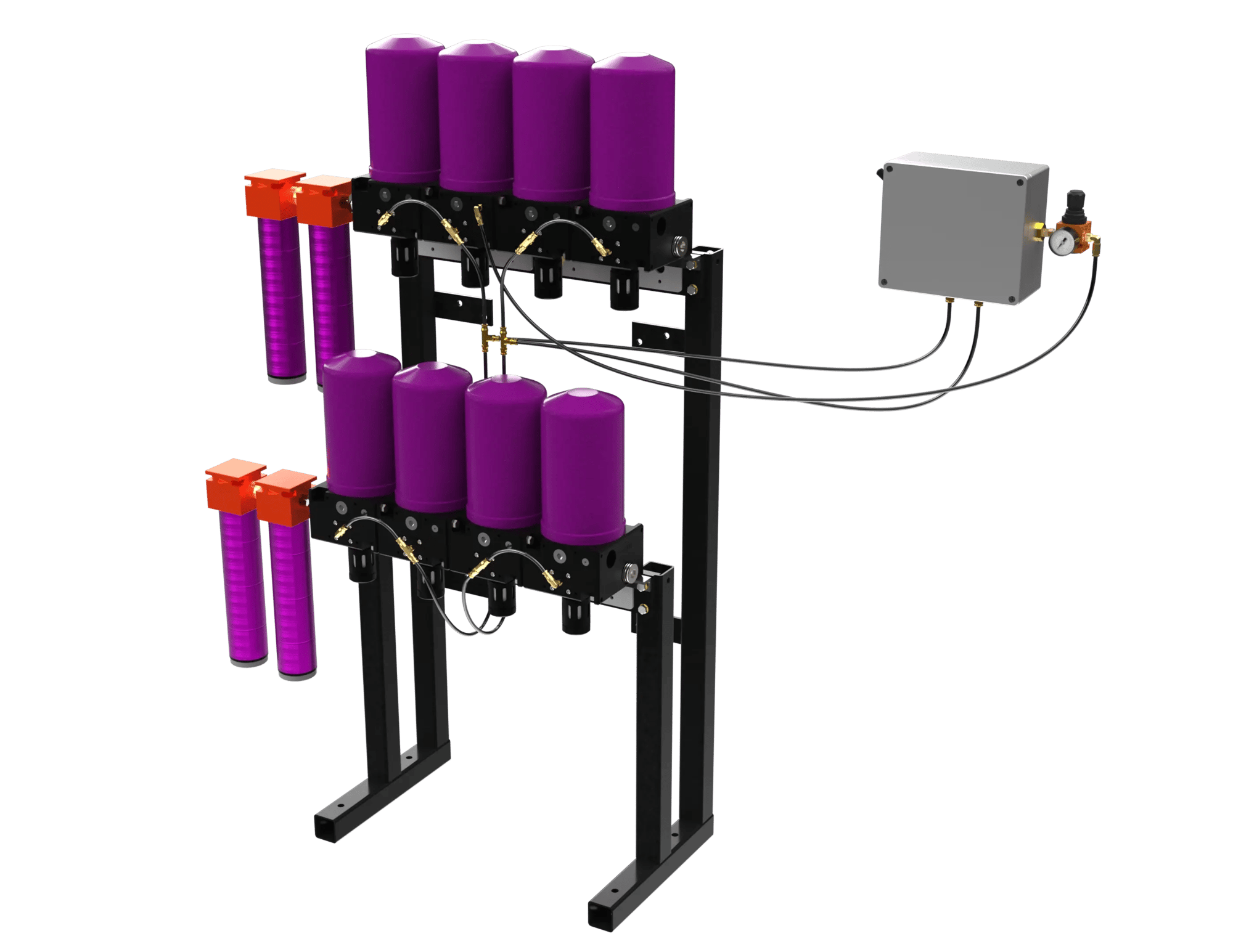

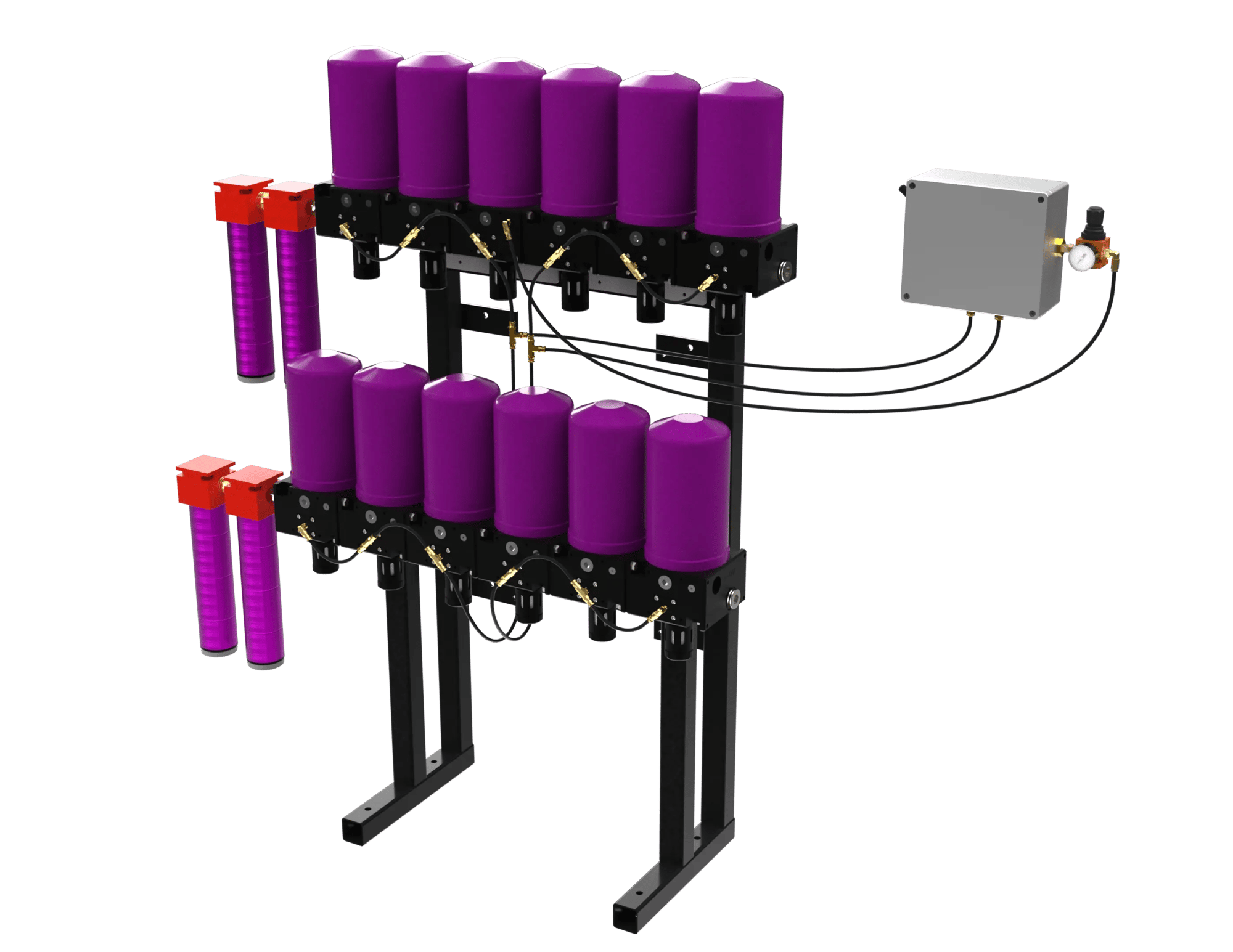

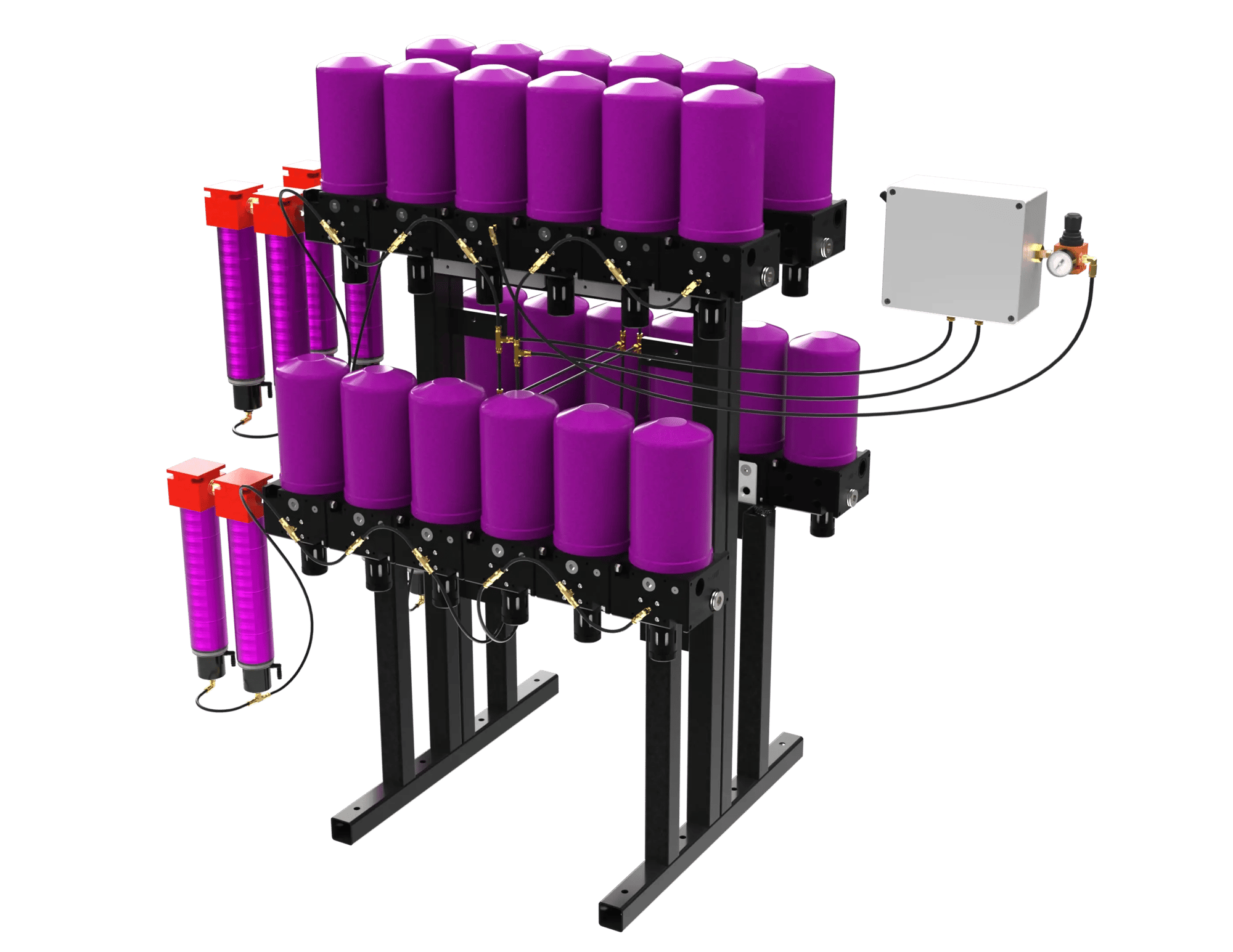

Engineered for Class 1, Division 1 hazardous locations, this regenerative pneumatic air dryer provides safe and reliable compressed air drying without the use of electricity. Designed for environments where flammable gases or vapors are present, it eliminates ignition risks while delivering clean, dry air to protect tools, equipment, and processes. Commonly used in oil and gas, chemical manufacturing, petrochemical plants, grain processing facilities, paint booths, fuel storage areas, and distilleries, this dryer is ideal for maintaining safety and performance in explosive or volatile conditions.

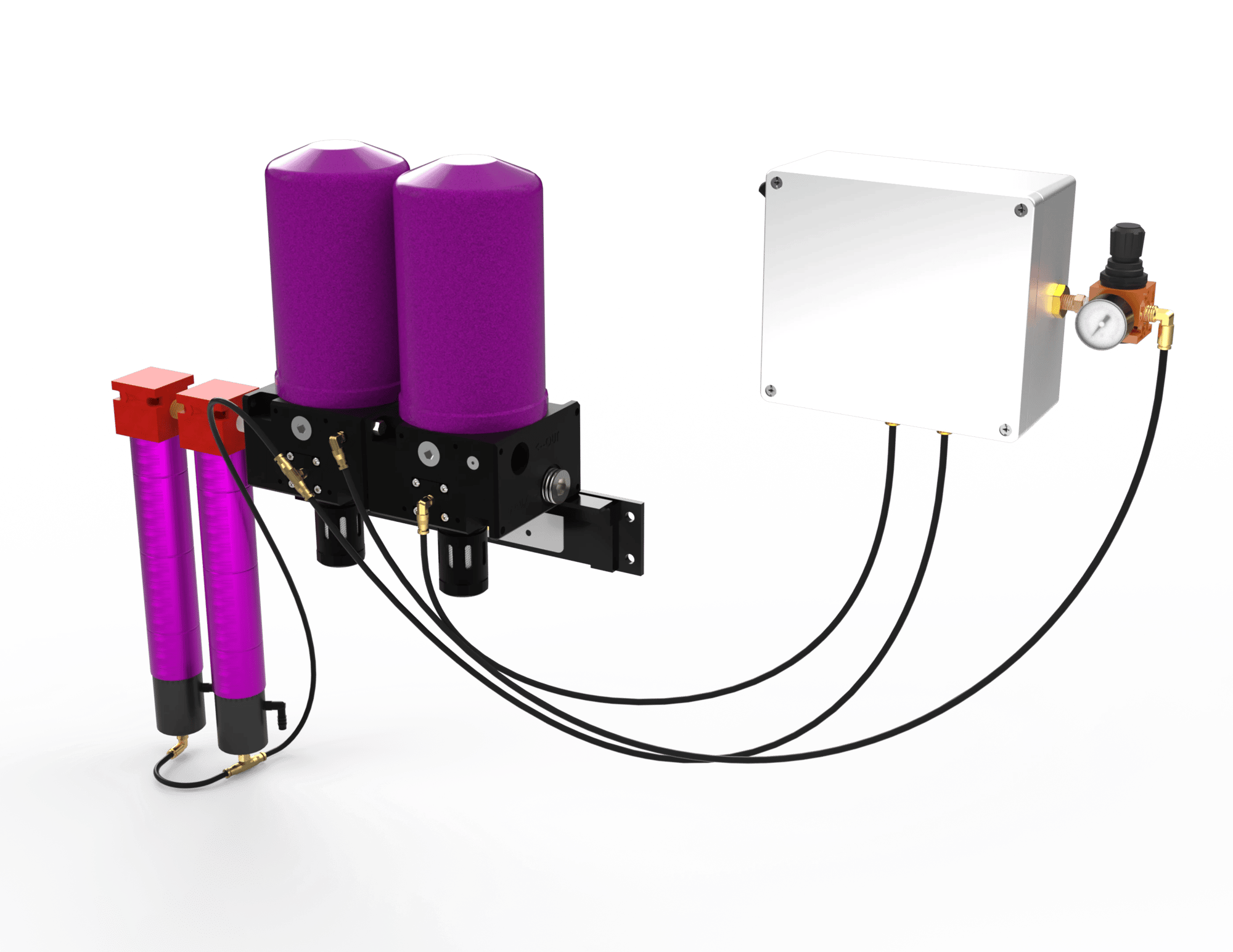

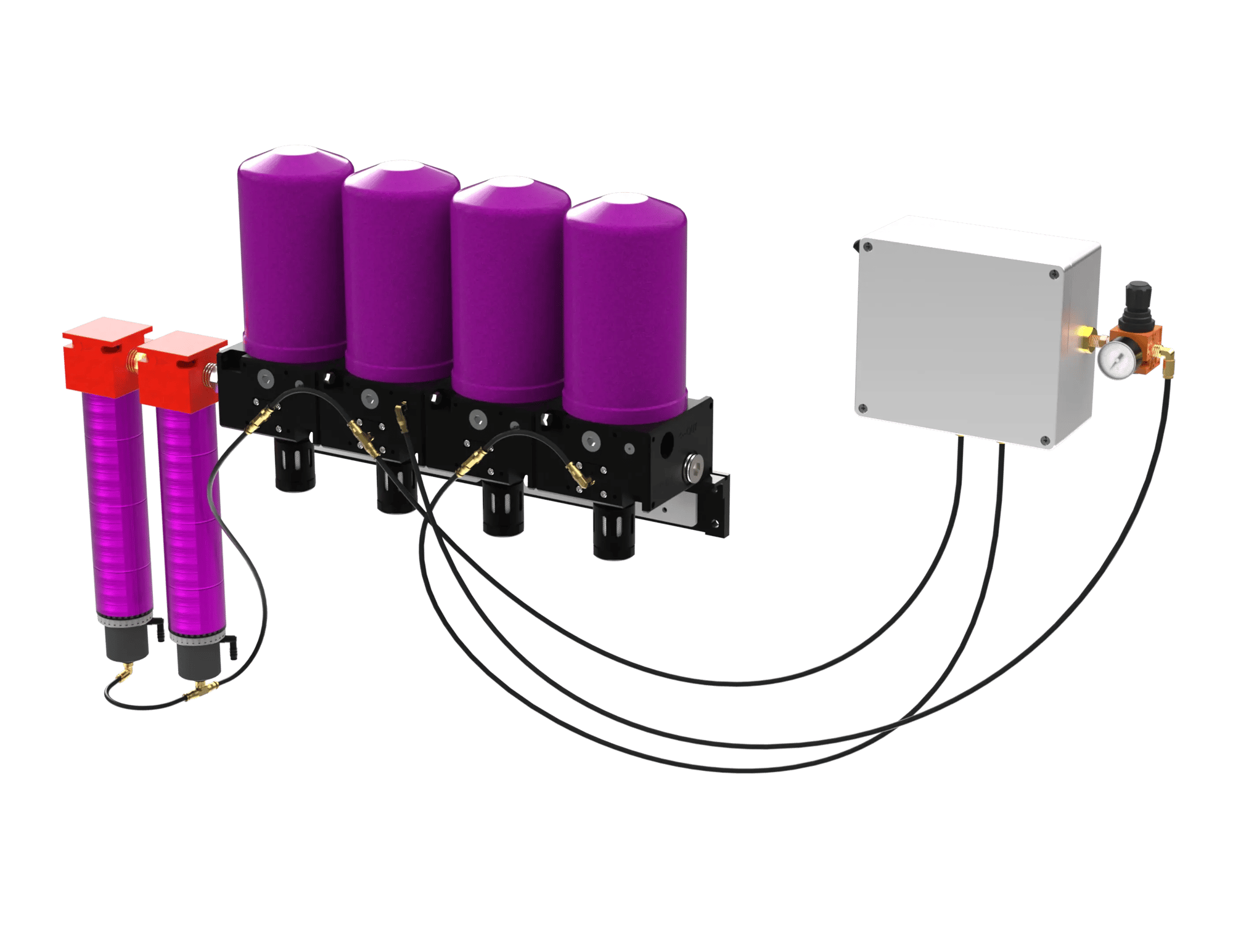

Tsunami Pre Filtration

Tsunami pre-filtration includes the water separator and oil coalescing filter to remove liquid water, bulk oils and particulate.

Regenerative Towers

Tsunami’s Regenerative Drying Technology uses sweep air to regenerate the towers during operation. It's like changing the desiccant every two minutes.

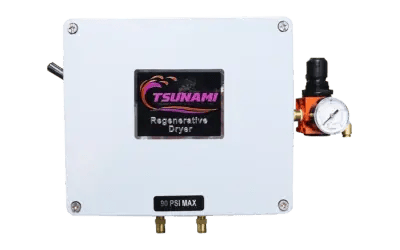

Explosion-Proof Components

The Pneumatic Timer Dryer Controller uses pneumatic timers to control dryer pilot sequencing. This means it doesn't need electricity, making it ideal for hazardous areas with flammable dust, vapors, and liquids, or locations where no electricity is available.

Features:

-

Pneumatic-powered Controller

-

Water Separator

-

Oil Coalescing Filter

-

Regenerative Dryer

-

Wall Brackets or Floor Stand Mount

-

Float Drains or Pneumatic Drains for Filters (NOTE: -MM models come with pneumatic drains that cycle every time the dryer cycles)

Benefits:

Dryer Performance:

-

No electricity required

-

Atex compliant components

-

Explosion-proof components

-

Low dew points to prevent freezing in air pipes

Filter Performance:

1st Stage Water Separator:

-

Removes liquid water

-

Filters particulate down to 10 micron

2nd Stage Oil Coalescing Filter:

-

Removes bulk oils and aerosols

-

Filters particulate down to .01 micron

Max Air Inlet Temperature: 150°F

Max Operating Pressure: 125 psi

Compressor Size Rating: 10-100 Hp

Flow Rates: 40-400 CFM

Water Separator: #21999-0082

-

Replacement Element: #21999-0228

Oil Coalescing Filter: #21999-0082-Z-FD

-

Replacement Element: #21999-0202

Air Consumption Averages and Cycle Time

| ITEM # | # of Towers | Orifice | CFM Consumption | Cycle Time | Tower Drying Time | # of Towers Drying | # of Towers Regenerating |

|---|---|---|---|---|---|---|---|

21999-1310 |

2 |

.03" |

1.6 |

2 min |

120 sec |

1 |

1 |

21999-1320 |

4 |

.03" |

3.2 |

2 min |

120 sec |

2 |

2 |

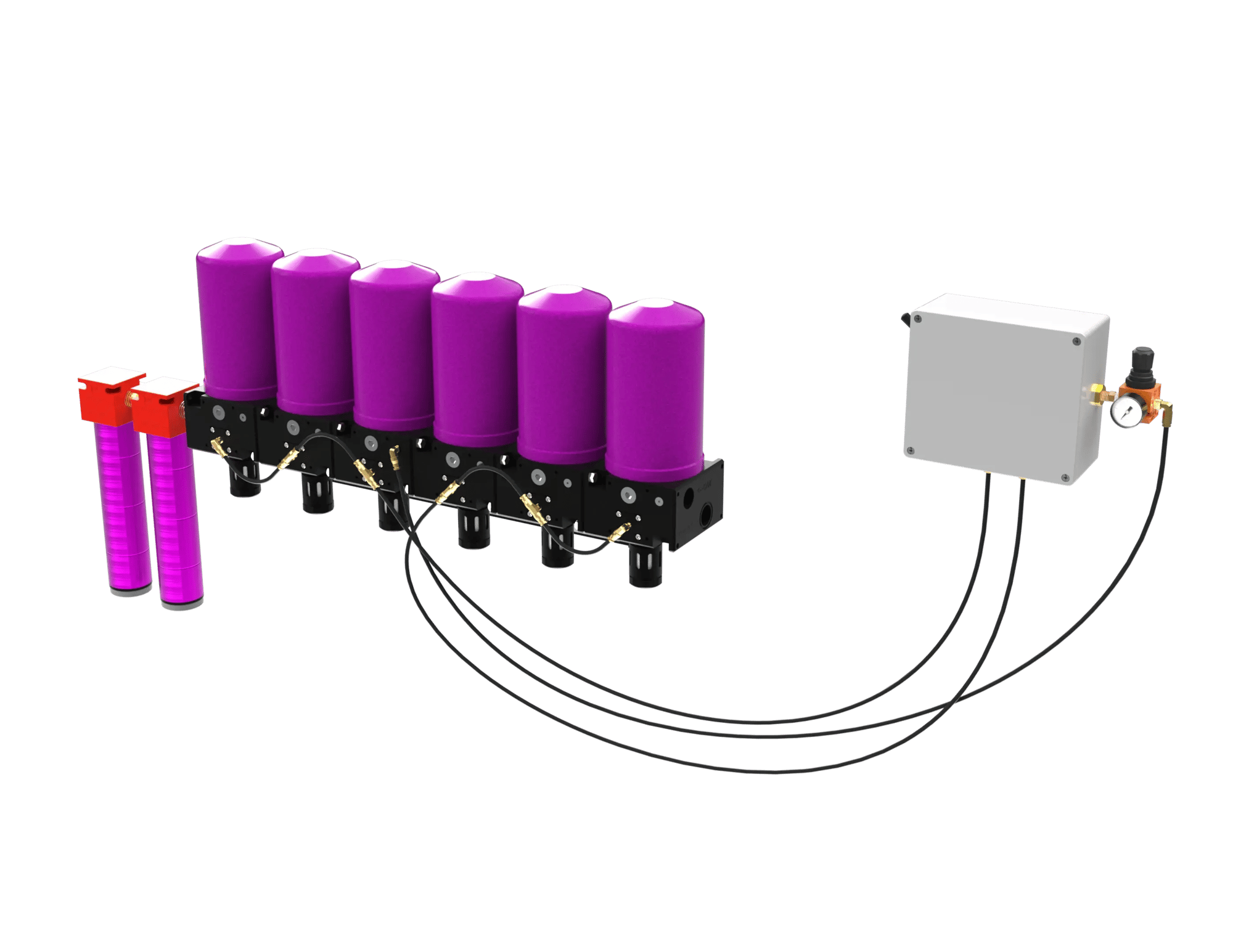

21999-1330 |

6 |

.03" |

4.8 |

2 min |

120 sec |

3 |

3 |

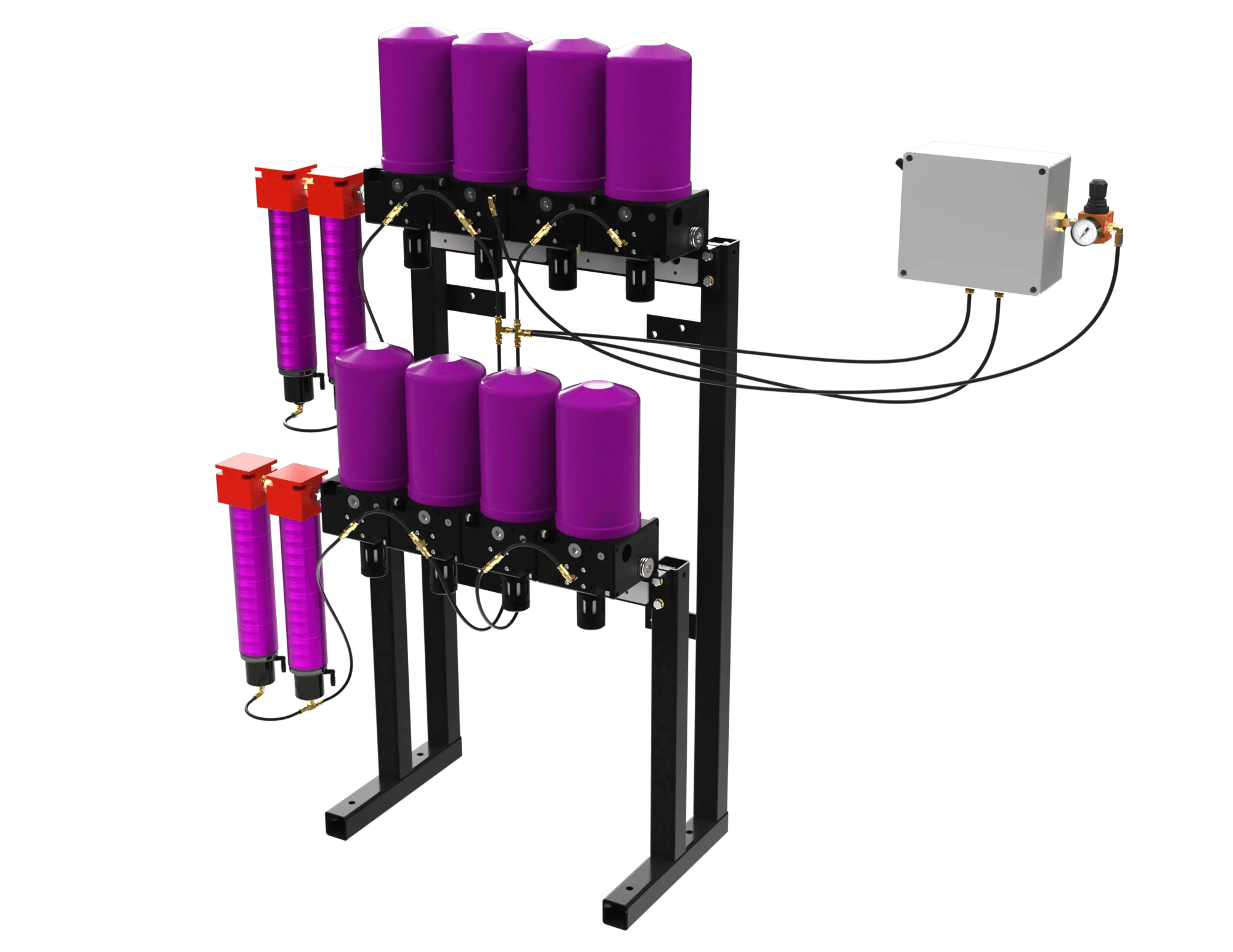

21999-1340 |

8 |

.03" |

6.4 |

2 min |

120 sec |

4 |

4 |

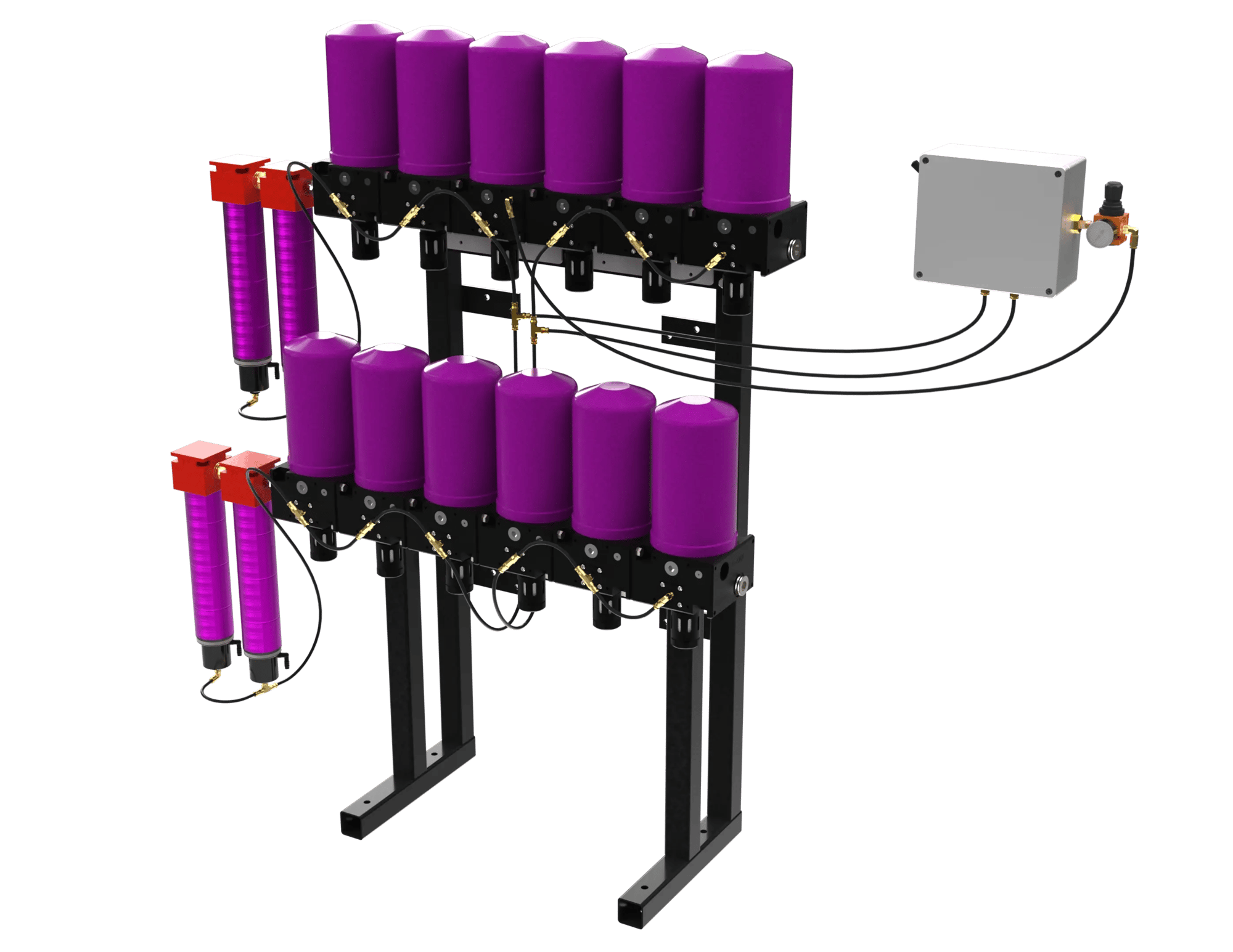

21999-1350 |

12 |

.03" |

9.6 |

2 min |

120 sec |

6 |

6 |

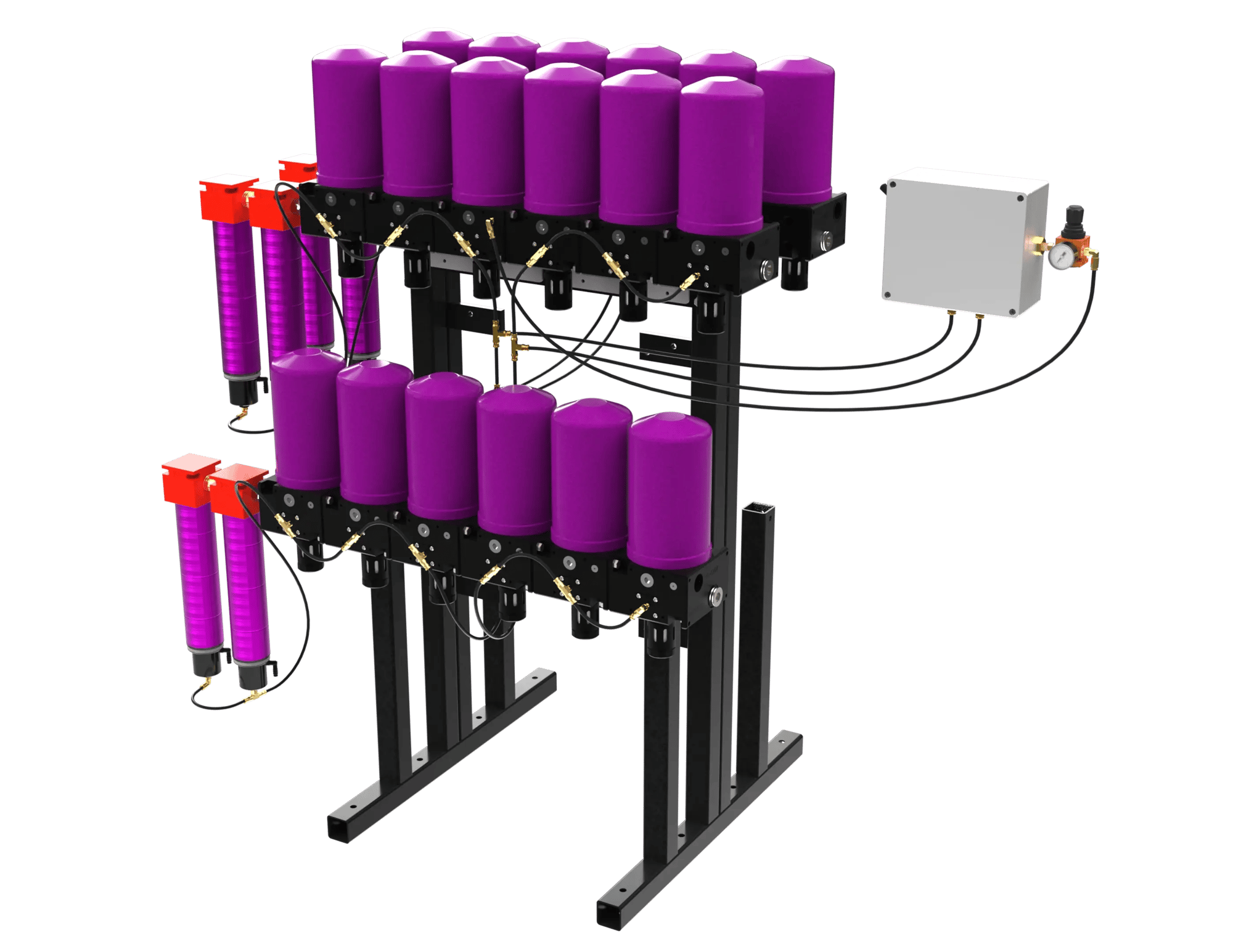

21999-1355 |

18 |

.03" |

14.4 |

2 min |

120 sec |

9 |

9 |

21999-1360 |

24 |

.03" |

19.2 |

2 min |

120 sec |

12 |

12 |

*Dryer flow rates based on 100°F at maximum 125 PSI. (Minimum inlet pressure 80 PSI Lower inlet pressure and higher temperatures affect the performance and quality of the downstream air)

Sizing & Ordering Information

| MODEL | ITEM # | # OF TOWERS | DRAINS | WATER SEPARATOR | OIL COALESCING FILTER | MOUNT | MSRP |

|---|---|---|---|---|---|---|---|

40 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1310 |

2 |

Float |

1 x 50 Series |

1 x 50 Series |

Wall |

$10,862.00 |

80 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1320 |

4 |

Float |

1 x 120 Series |

1 x 120 Series |

Wall |

$13,995.00 |

120 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1330 |

6 |

Float |

1 x 120 Series |

1 x 120 Series |

Wall |

$14,707.00 |

160 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1340 |

8 |

Float |

2 x 120 Series |

2 x 120 Series |

Rail |

$21,248.00 |

200 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1350 |

12 |

Float |

2 x 120 Series |

2 x 120 Series |

Rail |

$28,019.00 |

300 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1355 |

18 |

Float |

3 x 120 Series |

3 x 120 Series |

Rail |

$37,863.00 |

400 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Float Drains |

21999-1360 |

24 |

Float |

4 x 120 Series |

4 x 120 Series |

Rail |

$47,706.00 |

| MODEL | ITEM # | # OF TOWERS | DRAINS | WATER SEPARATOR | OIL COALESCING FILTER | MOUNT | MSRP |

|---|---|---|---|---|---|---|---|

40 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1310-MM |

2 |

Pneumatic |

1 x 50 Series |

1 x 50 Series |

Wall |

$11,396.00 |

80 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1320-MM |

4 |

Pneumatic |

1 x 120 Series |

1 x 120 Series |

Wall |

$14,529.00 |

120 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1330-MM |

6 |

Pneumatic |

2 x 120 Series |

2 x 120 Series |

Wall |

$15,241.00 |

160 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1340-MM |

8 |

Pneumatic |

2 x 120 Series |

2 x 120 Series |

Rail |

$22,313.00 |

200 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1350-MM |

12 |

Pneumatic |

2 x 120 Series |

2 x 120 Series |

Rail |

$29,085.00 |

300 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1355-MM |

18 |

Pneumatic |

3 x 120 Series |

3 x 120 Series |

Rail |

$39,463.00 |

400 CFM Class I Division 1 Hazardous Location Regenerative Drying System with Pneumatic Drains |

21999-1360-MM |

24 |

Pneumatic |

4 x 120 Series |

4 x 120 Series |

Rail |

$49,839.00 |

Product Video

Related Articles

5 min read

Air Purity in the Food and Beverage Industry

Tsunami Team: Dec 1, 2025

3 min read

Cycling vs Non-Cycling Refrigerated Air Dryers: What's the Difference?

Tsunami Team: Nov 7, 2025

© 2026 Suburban Manufacturing