2 min read

How to Prevent Hydraulic Hose Failure on Wet Kits

Python Covers Team

:

Aug 3, 2021 12:00:00 AM

For owners, operators, and contractors, dealing with on-site equipment failures not only means costly repairs but also added downtime and less profit. When it comes to heavy-duty hydraulic hose assemblies, failure in the lines is inevitable without proper maintenance and preventative care.

Hydraulic hose assemblies that are exposed to regular cycles of heavy friction need to be closely monitored for abrasion damage to prevent equipment failure and protect the safety of your workers.

What is a Wet Kit?

A Wet Kit, also known as a wet line kit, is a hydraulic system that consists of hydraulic hoses and fittings, reservoirs, filters, control valves, pumps, and a power take-off (PTO).

Wet kits are put on:

- Dump trailers

- Dump trucks

- Lowboys

- Live bottom trailers

- Moving and walking floor trailers

Wet Kits are utilized in heavy-duty and semi-trucks that have PTO which transfers the power of the transmission to a hydraulic pump, but they can be damaged by high temperatures and continued vibrations.

The Need for Wet Suits in Hydraulic Systems

Wet kits are mounted under or on the back of heavy-duty trucks, commonly used in the construction and transportation industries.

These trucks often experience off-road movement, leading to their hydraulic hoses rubbing along the catwalk of the truck and getting tangled with the other hoses. Since the hydraulic hoses do not have any protection against the diamond-plate catwalk, the hoses start to fray and weaken. The continued stress on these hoses increases the likely hood of failure, equipment damage, and possible operator injury.

Consequences of Hydraulic Hose Failure

Frayed hydraulic hoses can quickly become a serious safety hazard.

Wet kits are capable of producing pressure up to 3000psi, and that pressure changes frequently, causing the hoses to jump on the catwalk. If a hydraulic hose has a pinhole or bursts, serious injury can incur to the operator and equipment at hand. Injuries could include severe burns, lacerations, or amputations.

Minimizing the Risk of Hydraulic Hose Failure with Wet Suits

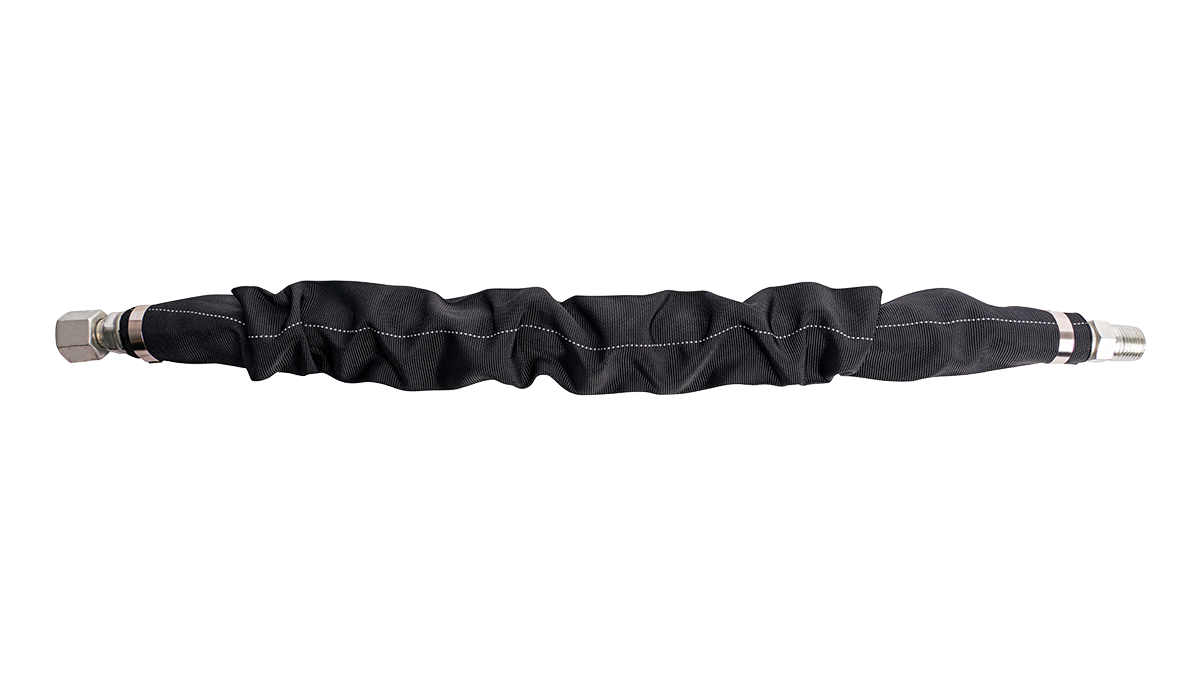

The answer to hose failure and abrasion on heavy-duty trucks is to put a protective sleeve over the hydraulic hoses.

Tightly woven constructed with proprietary fiber, the Diamondback Pro is designed to provide highly effective abrasion protection. Traditional abrasion sleeves have a looser weave made out of nylon, versus the Diamondback PRO, which uses polyester.

The Diamondback PRO not only is used for abrasion protection but also designed to protect operators and meets the EU Directive for Line of Sight and Burst Protection.

To compliment a protected hydraulic assembly, Python Protective Sleeve + Covers also offers a bundle straps and solutions. Utilizing the heavy-duty cinch straps your catwalk will be free and clear of hose failures.

Want to try it out before buying? No problem, request a FREE demo sleeve or speak to one of our experts at 1.800.782.5752.