3 min read

C1D1 Pneumatic Air Dryer for Hazardous Locations: Features & Benefits

Tsunami Team

:

Jul 1, 2025 8:00:00 AM

Tsunami Compressed Air Solutions Announces Pneumatic Air Dryer for C1D1 hazardous locations

In hazardous locations where flammable gases, vapors, and combustible dusts are prevalent, the need for safe and reliable air-drying solutions is paramount. Tsunami’s new C1D1 Pneumatic Air Dryer is engineered to meet this critical need, providing an innovative solution that functions without the requirement for electricity. This dryer is designed specifically for Class 1, Division 1 hazardous locations, ensuring that environments such as oil refineries, chemical plants, and grain elevators can operate safely and efficiently.

By eliminating the risk of electrical sparks, Tsunami's C1D1 Pneumatic Air Dryer substantially reduces the potential for explosions, making it a game-changer in environments where safety is the utmost priority.

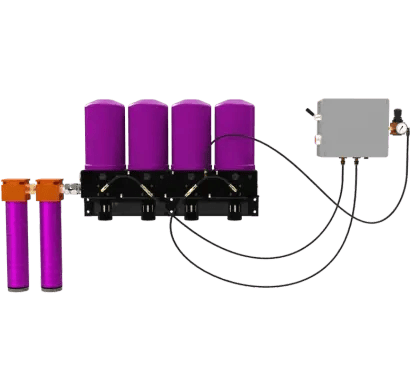

C1D1 Pneumatic Air Dryer

The C1D1 Pneumatic Air Dryer is the newest product to join the Air Dryers line, designed for industries in need of equipment that is ATEX compliant for hazardous locations, and any applications that do not have access to electricity.

- Pneumatic-Powered Controller: The controller allows the system to operate without electricity, greatly reducing the risk of ignition in volatile environments.

- Water Separator and Oil Coalescing Filter: This filter package ensure the compressed air is free from moisture and oil which can compromise the safety and efficiency of pneumatic tools and equipment.

- Regenerative Dryer: The dryer provides low dew points to prevent freezing in air pipes; this ensures consistent operation even in extreme conditions.

- Mounting Options: The dryer package includes wall brackets or a floor mount stand, allowing for flexible installation based on the specific needs of the facility.

- Float Drains or Pneumatic Drains for Filters: These options ensure proper dispersal of contaminants captured in the filters.

COMMON INDUSTRIES & APPLICATIONS

- Oil & Gas: Refineries, drilling rigs, and production sites benefit from the dryer's ability to provide clean, dry air without the risk of igniting flammable gases.

- Chemical Manufacturers: Ensuring safe and efficient operations in facilities where volatile chemicals are produced and stored.

- Grain Elevators & Flour Mills: Protecting against the ignition of combustible dust in agricultural processing facilities.

- Paint Facilities: Maintaining safe air quality in environments where flammable paint vapors are present.

- Woodworking & Textile Mills: Ensuring the safety and longevity of pneumatic tools and equipment in dusty environments.

No electricity, no problem

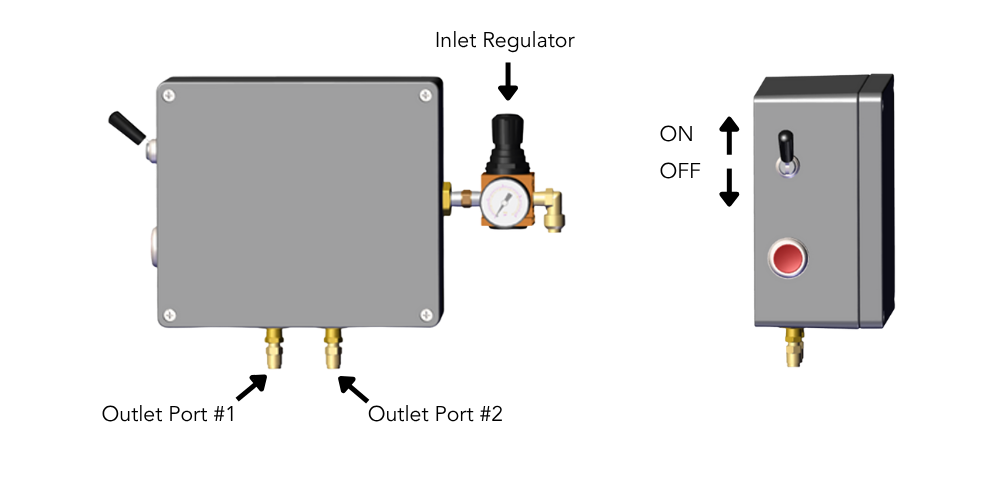

One of the standout benefits of the Tsunami C1D1 Pneumatic Air Dryer is its ability to operate without electricity. This feature is crucial for environments where electrical equipment poses a significant risk of ignition. By using a pneumatic timer controller, the dryer can be placed in any electricity-free facility or area, ensuring safe operation in even the most hazardous locations.

How it works

- Air supply in: compressed air enters the inlet port

- Control signal: sends pulse of air to trigger timer

- Timer delay begins: the timer restricts the airflow using an adjustable orifice. This slows down air pressure build-up, creating a delay

- Trigger or output action: pressure opens/closes another valve

Explosion-proof: Safety First

Engineered with ATEX certification and integrated explosion-proof components, the C1D1 Pneumatic Air Dryer demonstrates Tsunami’s commitment to uncompromising safety and operational reliability within hazardous environments where flammable substances are present.

“Tsunami’s new C1D1 Hazardous Location Desiccant Dryer is uniquely positioned to be the most versatile technology available. With our ability to solve dry air needs for compressor system entirely, as well as targeted point of use applications, this design will meet all requirements for gas and dust atmospheres. With the understanding that many systems are engineering to eliminate the need for C1D1 equipment, our technology eliminates that concern as our equipment does not have to meet the NFPA and NEC regulations surrounding electrical use in hazardous locations as all controls are pneumatically driven."

- Troy Robins, Tsunami Product Manager

How to Order

Part numbers associated with this new product:

- C1D1 Air Dryer - 40 CFM 21999-1310

- C1D1 Air Dryer - 80 CFM 21999-1320

- C1D1 Air Dryer - 120 CFM 21999-1330

- C1D1 Air Dryer - 160 CFM 21999-1340

- C1D1 Air Dryer - 200 CFM 21999-1350

- C1D1 Air Dryer - 300 CFM 21999-1355

- C1D1 Air Dryer - 400 CFM 21999-1360

- C1D1 Air Dryer - 40 CFM 21999-1310-MM

- C1D1 Air Dryer - 80 CFM 21999-1320-MM

- C1D1 Air Dryer - 120 CFM 21999-1330-MM

- C1D1 Air Dryer - 160 CFM 21999-1340-MM

- C1D1 Air Dryer - 200 CFM 21999-1350-MM

- C1D1 Air Dryer - 300 CFM 21999-1355-MM

- C1D1 Air Dryer - 400 CFM 21999-1360-MM

To learn more about the Tsunami C1D1 Pneumatic Air Dryer or place an order, contact your Tsunami sales representative.