In the oil and gas industry, pneumatic timer controllers play an important role in environments where having a secure electrical connection is hard to come by, and where electricity may pose a danger to workers and operations alike.

The number one goal in any industry is to protect employees and have the safest working conditions possible. This is best achieved with the help of a pneumatic timer controller. By installing a pneumatic timer onto your equipment, operations are able to improve for the better.

In this article, we'll discuss the function of a pneumatic timer control and the importance of adding one to your air dryer:

- What is a Pneumatic Timer Controller?

- How does a Pneumatic Timer Controller Work?

- Benefits of adding a Pneumatic Timer to Your Dryer

- Pneumatic Timers: Upgrade Your Compressed Air Dryer

What is a Pneumatic Timer Controller

A pneumatic timer controller is a piece of equipment designed to control the precise actuation of air output pilot signals. They utilize two pneumatic timers within the internal circuit to control which outlet pilot signal to turn on and which to turn off and vent the pilot air.

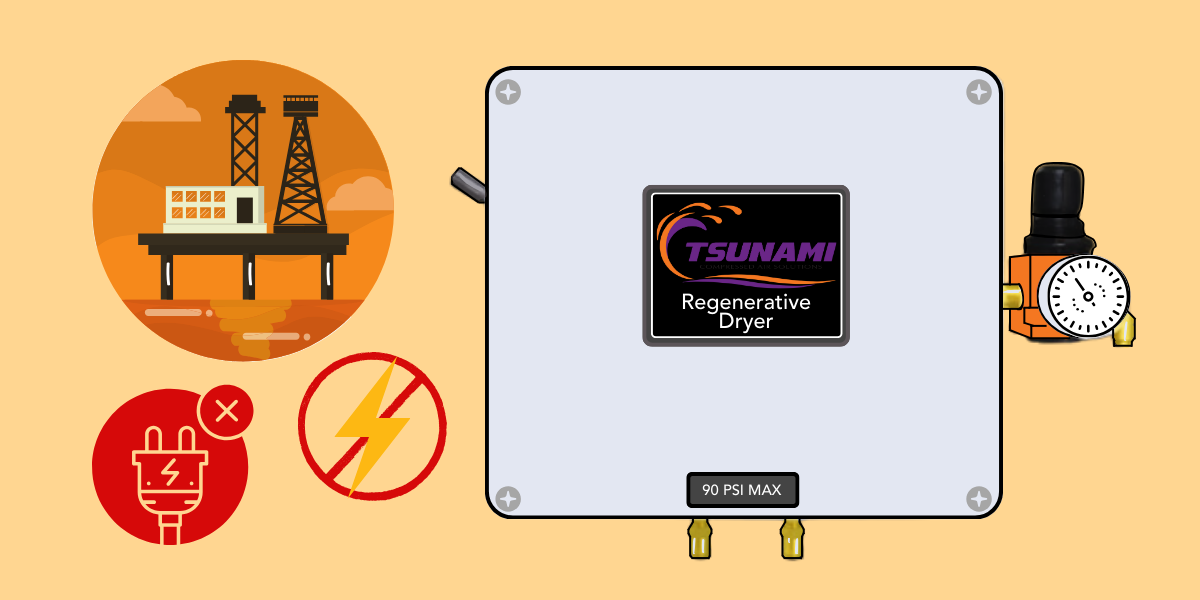

Pneumatic timers are an alternative to electronic timers because they can be installed in spots where there is no accessible electricity, or where it may be dangerous to use electrical timers - such as in C1D1 hazardous zones.

Due to the pneumatic timer's ability to operate without electric, it's ideal for the oil and gas industry and mining, but can be used in a variety of industries where electricity is inaccessible, hard to get to, or dangerous as mentioned above.

A pneumatic timer works differently than an electronic timer; let's dive into how it runs without electric power.

How does a Pneumatic Timer Controller Work?

The pneumatic timer is unique because it can run without an electrical current. Due to the lack of electricity, its internal components function differently; the basic parts of a pneumatic timer controller are a solenoid core, timing disk, filter, diaphragm solenoid coil, and operating spring.

This is how a pneumatic timer works when in operation:

- The solenoid core enters the solenoid coil

- Pressure is applied to the diaphragm solenoid coil from the core

- Once pressurized, the diaphragm moves to the top of the chamber to entrap the air there

- The air trapped in the chamber exits the needle in the timing valve disk

Controlling the Pneumatic Timer

To control the timing, adjust the valves until the desired delay is reached. It's important to keep in mind that pistons control the speed of the air entering into the system, whereas the valves control the speed and timing of which the air leaves. The timer makes it possible to choose the timing between the opening and closing of a valves, which allows precision in timing and smoother operations.

Benefits of Upgrading to a Pneumatic Timer Controller

There are many benefits of installing a timer controller to your pneumatic system. Its easy operation, simple installation, and reliable results are just a few of the advantages a pneumatic timer controller offers. A timer controller has its advantages in industrial settings for a few reasons:

- Precision Every Time:

with precision, it can offer consistent air pressure to your equipment and systems for consistent results - C1D1 Hazardous Location Ready Solution:

due to the timer operating on pneumatic air, it can be situated in high-risk locations; this allows operations to continue smoothly, while ensuring the safety and well-being of workers - No Electricity Required:

this pneumatic timer operates and functions on air; not needing an outlet means flexibility on where it's placed, and extra safety if in highly flammable environments - Increases Workplace Safety:

when used as an electric timer replacement, a pneumatic timer lowers the risk of electrical-based incidents - Reliable:

you can set-and-forget a pneumatic timer due to its reliable, dynamic technology - Versatile:

a pneumatic timer controller is a small, light device, allowing for it to be installed wherever it may be needed in a workplace - Easy to Install:

part of the reason a timer controller is so versatile, is because it's easy to install on any application you need it for

Pneumatic Timers: Upgrade Your Compressed Air System

Pneumatic timers are an innovative technology that allows for precise pilot air signals to power equipment. Without having to worry about electrical wiring, cords, or hazardous fires, pneumatic timer controllers offer a stress-free operating experience. This is especially true in C1D1 locations where the possibility of a fire is high; the use of a pneumatic timer decreases the risk of operator injury and equipment damage.

The oil and gas industry, mining, and more greatly benefit from the reliability and safety a pneumatic timer brings to a job site. If you are looking for a solution with low-maintenance, lasts, and increases safety a pneumatic timer checks all of the boxes.

If you are looking to learn more, contact our compressed air experts to see if a pneumatic timer controller will benefit your system. Ready to purchase one of your own? Check out our distributor locator to find a pneumatic timer controller near you.