It's important to take care of compressed air systems, and one of the best ways is with air filters. There are three primary types of filters, each offering a specific way to filter out damaging air contaminants and particulates. The three most common compressed air filters are water separators, oil coalescing, and activated carbon. Let's go over all three, and talk about what each one can do to benefit the air going through your compressed air applications.

In this article, we'll be discussing what what each compressed air filter pulls out:

- What is an air filter?

- How do air filters work?

- Air filters and their functions

- The best air filter solution

What is an air filter?

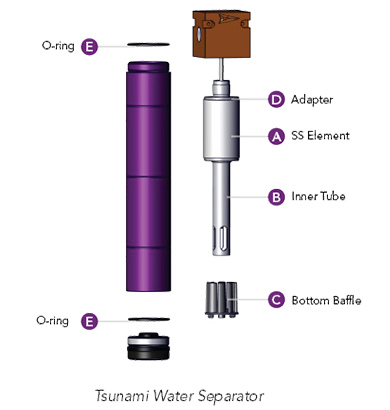

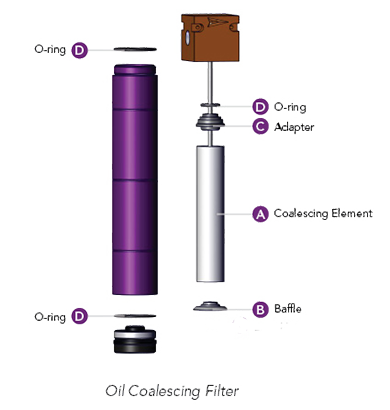

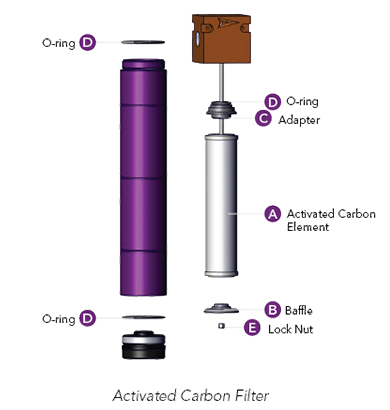

An air filter is a piece of technology used to filter out contaminants such as oils, dust, water, and any other particulates lingering in the air. Air filters are usually made up of a housing with an internal element that removes the above mentioned contaminants. Many elements have layers to catch and pull out these contaminants throughout the filter's specific process. This process varies depending on what the air filter is designed to clean out of the air.

How do air filters work?

An air filter, when attached downstream of an active air compressor, allows air to flow through it to the downstream application. As the air is flowing through the filter, it pulls out the contaminants and deposits them in the drain sump or physically traps them within the element itself. Almost all filters have a drain which allows the removal of these trapped deposits.

Air Filters and their Functions

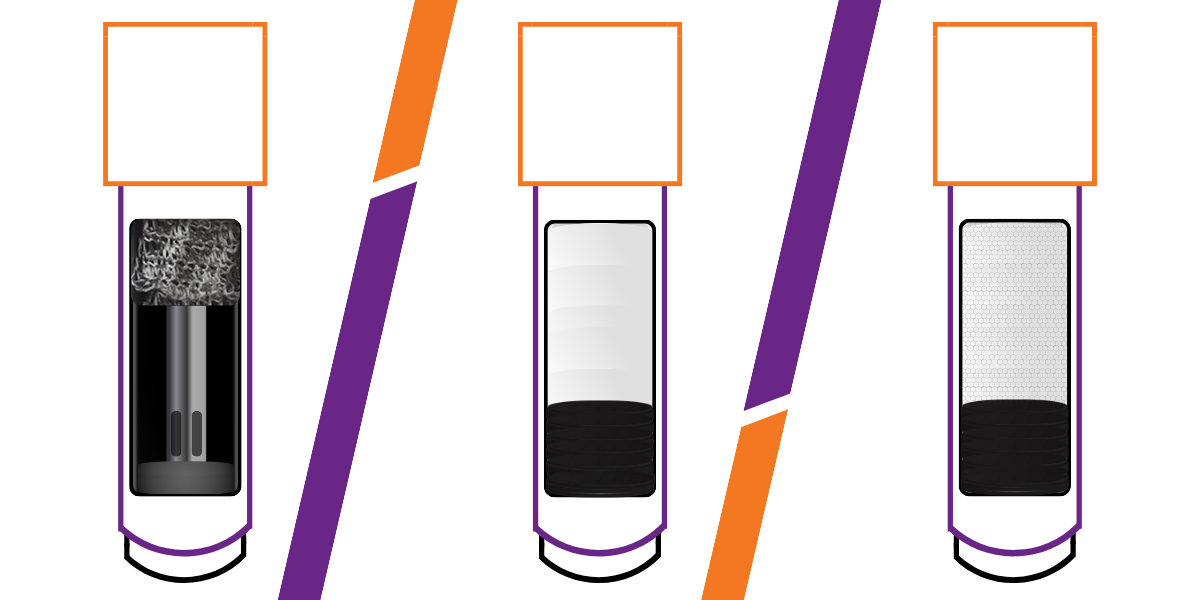

Three primary types of compressed air filters are shown below. Some work effectively for a specific application or requirement by themselves, many are designed to work together for maximum air cleanliness.

The three air filters are:

Water Separators

Maintenance: minimal

Removes: bulk liquids (water and oil) and particulates (dirt, dust, debris)

Filters particulate: down to 10 micron

Made out of: anodized aluminum

Wondering what makes Tsunami's water separator different? Download the comparison guide here!

The best air filter solution

The best air filter solution for your compressed air application is also the best air filter solution for you. Whether it's for painting, air drying, food and beverage or any other industrial application - air filters are built to improve efficiency, cost, and value - no matter the industry. If you are ready to get started on your air filter journey, we have you covered. Tsunami offers water separators, oil coalescing filters, and activated carbon filters to fit your application needs.

Don't know where to start? We're here to help. Contact a compressed air professional to learn the basics and feel confident with your Tsunami compressed air solution.