4 min read

The Ultimate Hydraulic Hose Protective Sleeve for Extreme Conditions

Python Covers Team

:

Feb 14, 2022 12:00:00 AM

Hoses and assemblies take a beating on job sites where the environment shows no mercy.

Industries like mining, subsea oil service, geological exploration, and oil and gas drilling have demanding conditions surpassing traditional industrial applications.

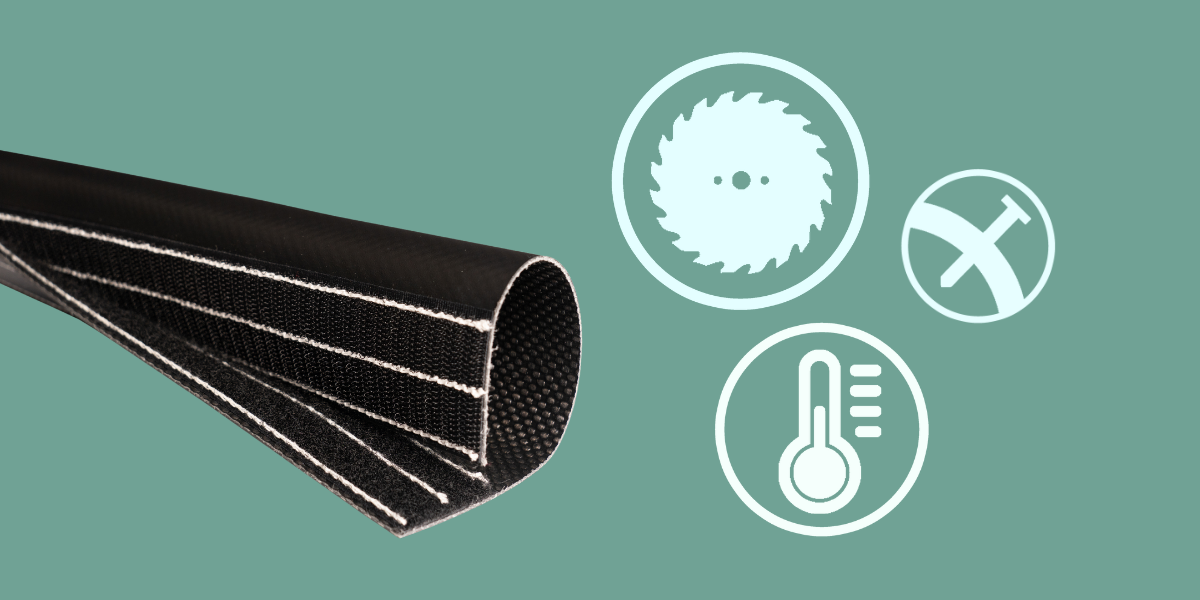

To combat these rigorous challenges, it's essential to employ abrasion protection sleeving that ensures both longevity and efficiency of equipment. The 40 HDA Heavy Duty Abrasion Sidewinder Sleeve is specifically designed to withstand these harsh conditions, providing unmatched durability and reliability.

Let’s explore the features and benefits of this innovative protective sleeve for hydraulic hoses, highlighting its role in enhancing the performance of hydraulic systems, focusing specifically on an example in the oil and gas industry.

The Hydraulic Hose Protective Sleeve for Abrasive Environments

When faced with these relentless environments, the 40 HDA wrap sleeve is the ultimate defense for your heavy-duty hoses. Crafted from a military-grade, 1500 denier fabric and reinforced with a proprietary polymer, it's twice as heavy and six times more abrasion-resistant than any other Sidewinder product. Unlike standard wear protection, this sleeve offers full hose coverage in the toughest conditions.

For more demanding applications, the 40 HDA Sidewinder Sleeve can be equipped with additional reinforcement for maximum wear resistance.

Equipped with a cutting-edge, military-spec hook and loop closure, the 40 HDA can be easily applied after hose assembly. This unique design significantly reduces installation and maintenance expenses by as much as 70%.

Want to See Our Extreme Hook and Loop Closure in Action?Our Sidewinder Protective Sleeves are designed for use in greasy, dirty, and grimy situations. Our proprietary fastener works even in the toughest situations. See it in action: |

The 40 HDA Sidewinder Sleeve is exceptionally durable, meeting stringent ISO 6945 standards with an impressive abrasion resistance of over 500,000 cycles. It is engineered to withstand harsh environments, exhibiting excellent resistance to petroleum, saltwater, gasoline, and other chemicals. Designed for safety, it is MSHA-approved for use in mining applications. Additionally, it offers superior UV protection that surpasses EN13758-1 standards and features static dissipative properties.

A Look at the 40 HDA Wrap Sleeve |

|

|

Material |

Proprietary Polymer Coated 1500 Denier Substrate 40oz. sq. yd |

|

Temperature Range |

Ambient -35°F (-37°C) to + 225°F (107°C) |

|

Abrasion Resistance |

Outstanding, tough, heavy weight. Meets ISO 6945 Specifications, 500,000+ cycles |

|

Puncture/Tear |

Excellent |

|

UV Protection |

Excellent; meets EN13758-1, top rating of 80 New |

|

Chemicals |

Very good resistance to water, petroleum products, and detergents |

|

Wicking |

Non-Wicking |

|

Certifications |

MSHA approved, MSHA - IC289 |

|

Typical Applications |

Mining, sub-sea oil service, frac and mud pumping hose, rotary drill hose, forestry skidders, knuckle boom loaders, drill jetters |

Severe Conditions Will Reduce Hose Life

Given the immense forces and heavy equipment involved in the oil and gas industry, hoses are going to take an immense beating. Coupled with the crippling costs of downtime, implementing high-performance, abrasion-resistant hydraulic hose sleeves as a mandatory component for your extreme operations will not only keep your hoses functioning longer but save your company money.

Let’s examine several factors that can dramatically reduce hose life:

- High winds

- Chemical Exposure

- Weight

- Vibrations

- Abrasive Environments

High Winds

The immense weight of a 4-inch, 6000 psi rotary drill hose (approximately 5000 pounds) makes it vulnerable to high winds. Persistent gusts of 50-70 mph can violently propel the hose into the rig frame, causing critical damage to its protective covering.

Chemical Exposure

Beyond physical challenges like abrasion and impact, oilfield operations often demand exceptional chemical resistance. Exposure to harsh substances such as drilling fluids and corrosion inhibitors can severely degrade the elastomers in rubber and plastic hoses and their protective coverings, reducing their lifespan by up to 50%.

Weight

Weight exacerbates the abrasive conditions faced in these applications. As the hose operates, it dips and rests on large machinery whose protrusions and edges create concentrated wear points. The hose's vibrations induce an ultrasonic-like motion, which, compounded with the weight, rapidly accelerates wear.

Vibrations

In the volatile environment of the oil and gas industry, vibrations are an inevitable factor that contributes to hose wear and tear. As machinery operates, the constant movement creates oscillations that can lead to fatigue in hoses over time. These vibrations can cause hoses to rub against each other and adjacent materials, which ultimately compromises their integrity and shortens their lifespan.

Heavy-duty protective hose sleeves like the 40 HDA Sidewinder serve as a crucial barrier against these harmful effects by minimizing friction and providing an additional layer of protection that mitigates the impact of vibrations. This enhancement is essential not only for maintaining operational reliability but also for ensuring safety on the job site.

Abrasive Environments

The 40 HDA underwent rigorous real-world testing on drilling rigs and service provider applications. The accompanying image showcases drag test results from jet dredge operations, where the 40 HDA was evaluated as a protective covering for umbilicals. Subsea environments present the most demanding challenges, especially during inspection and storage preparation when the massive 600-foot umbilical hose bundle, exerting a ground pressure of 40 psi, is dragged across rough concrete docks.

Challenges with Traditional Hose ProtectionTraditional hose wrap protection methods often present significant hurdles. Sleeves designed for individual hoses can be incredibly time-consuming to install, especially for longer lengths. Moreover, bundled hose sleeves create their own set of problems. When a single hose within the bundle requires maintenance, accessing it without contaminating the system becomes a complex and time-consuming task. Replacing a damaged sleeve in a bundled configuration often necessitates removing all hoses, a process that is both inefficient and costly. The Sidewinder Hydraulic Hose Protective Sleeve SolutionPython Sidewinder Sleeves offers a superior alternative to traditional hose protection. This innovative product is produced in a flat roll format, making it easy to handle and cut to the desired length. Its unique coating ensures smooth application over sharp edges, while a special adhesive prevents unraveling in case of damage. Sidewinder’s robust construction, featuring redundant threads and a strong hook and loop closure, guarantees durability and secure installation. Perhaps most importantly, Sidewinder is designed for easy replacement. If a hose or sleeve is damaged, it can be quickly and efficiently repaired without disrupting the entire system. Available in standard sizes from 1 to 8 inches, with custom options for specific needs, Sidewinder provides a versatile and effective solution for protecting hydraulic hoses. Watch the video below to learn more: |

The Solution For Abrasion and More: How Python Can Help

If extreme environments are taking a toll on your equipment and causing delays in your operations, Python offers the hydraulic hose protective sleeve you need.

Python specializes in manufacturing revolutionary products that protect both operators and equipment. With expertise in fluid power, proprietary technology, and top-tier customer service, we deliver innovative, reliable, and user-friendly solutions. Python provides military-grade products for the agriculture, defense, mining, and construction industries.

Our skilled engineering team is ready to assist with your custom solutions. Discover the power of the 40 HDA Wrap Sleeve and request a sample today:

(Editor’s note: This article was originally published in February 2022 and was updated in August 2025.)