2 min read

Extend Hose Life with Diamondback Lite Sleeves

Python Covers Team

:

May 8, 2023 8:56:58 AM

Hydraulic hose performance has a direct impact on job success. A pinhole leak or other issues with a hydraulic hose can mean extensive downtime - not to mention the risk of injury or death for the workers on-site.

Extending the life of your hydraulic hoses by investing in a protective hose sleeve means smoother operation for the job at hand and reliability for the future as well. This in turn means less downtime and greater productivity.

Diamondback Lite Tubular Sleeves resist factors that interfere with hydraulic hose operation, leading to hose failure. These sleeves also ensure project continuity when it is most necessary.

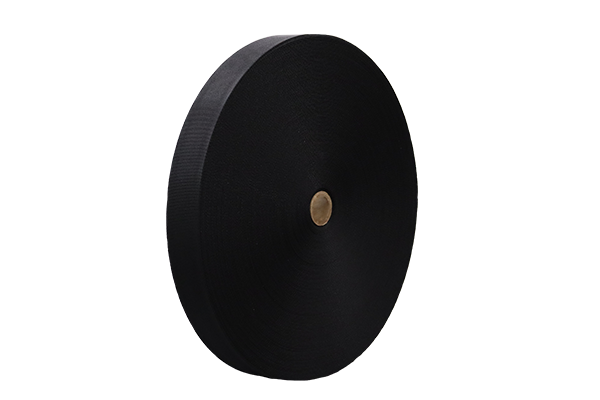

A Look at the Diamondback Lite Sleeve

This sleeve is commonly used in agriculture, construction, and mobile equipment applications. Woven tightly and heat-treated, this nylon sleeve is made from a proprietary engineered fiber to provide UV and abrasion resistance at an affordable price.

The Diamondback Lite sleeve meets conductivity standard ISO 8031. The product can be cut to length with scissors. When exposed to temperature, the Diamondback Lite can withstand up to 350°F intermittently and up to 200°F continuously. Tested to ISO 6945, the Diamondback Lite performs to and exceeds 40,000 abrasion cycles.

5 Reasons Diamondback Lite is the Protection Sleeve for Your Hydraulic Hose

Without protective sleeve, the life of hydraulic hoses can be shortened dramatically. However, it is important to remember that span decreases significantly with consistent exposure to weather, abrasive surfaces, and other external factors. Agriculture, construction sites, and mobile equipment are all areas where the Diamondback Lite provides reliable operation.

When outfitted with a protective sleeve, a hydraulic hose can last longer, as exposure to abrasion and various other impediments is reduced.

Like other members of the Diamondback hose sleeve family, Diamondback Lite is designed to help you get the most from your hydraulic hoses by providing hose protection:

- UV Protection: Continued exposure to the sun weakens hydraulic hoses, leaving them brittle and prone to leaks or bursts. Taking care to calculate exposure time for your hydraulic hose and also to the pressure within can make a difference in extending hose life.

- Abrasion Resistance: Abrasions are weaknesses caused by consistent pressure from rough surfaces. Diamondback Lite provides abrasion resistance to help reduce the effects of environmental conditions - allowing the job to continue to completion.

- Lightweight: Heavy hoses can significantly impact equipment performance by weighing down the machinery and causing pressure on connections. Likewise, the location of the hose and the weight it adds to the equipment can influence the operation of the machinery. Therefore, it is important to find a reliable hose that minimizes its contribution to the weight the equipment carries. Diamondback Lite sleeves are economical and lightweight.

- Flexible: When it comes to rigidity in hydraulic hoses, the correlation of strain and fatigue to hose tension is a direct one. The Diamondback Lite is flexible and moves with the hose, creating less strain on the line while providing protection. Remember: Flexibility and minimum bend radius are not the same things.

- Professional Look: The Diamondback Lite provides a cleaner look while protecting the hydraulic hose.

Think Ahead to Extend Hydraulic Hose Life

Hydraulic hoses provide reliability and safety throughout the entirety of a job - provided they are protected from external influences.

Proactive planning on the job site means a smoother operation and reduced risk of delays. Remember: a protective sleeve is one part of a multi-step approach to protect hydraulic hose:

- Make sure all employees are properly trained on how to handle hydraulic hoses safely, as well as to replace them when necessary.

- Keep a regular maintenance schedule for the hoses, inspecting them regularly for signs of wear or damage.

- Provide adequate protective gear for employees when handling hydraulic hoses, such as gloves, safety glasses, and protective clothing.

- Have an emergency plan in place in case of any sudden failure of a hose, so that the situation can be addressed quickly and safely.

Further Resources for Hydraulic Hose Protective Sleeves

Keeping your hydraulic hoses safe and secure with hose guards is an important part of any job. Our team is committed to finding the right hose protection solution for your application.