2 min read

Diamondback vs Diamondback PRO: A Full Comparison

Python Covers Team

:

Aug 12, 2022 1:00:56 PM

The Diamondback and Diamondback PRO tubular sleeves are ideal for operator and equipment safety. Flexible and easy to install, Diamondback also features line-of-sight, pin hole, and burst protection.

INDUSTRY SAFETY LEADERS

Both Diamondback and Diamondback PRO meet industry regulated standards:

- “Line of Sight” operator protection specification EN982, EN414, EN ISO Regulation 3457:2008

- Conductivity standard ISO 8031

- Mine Safety and Health Administration (MSHA) approved IC-289/01

- EU Machinery Directive 2006/42/EC

- NSW “Guideline for Fluid Power System Safety at Mines”

PINHOLE AND BURST PROTECTION

Hydraulic hose pinhole leaks act much like a hypodermic needle, piercing the skin and injecting hydraulic fluid into nearby people. The Diamondback tubular sleeve prevents such injuries from ever taking place by stopping pinhole leaks and bursts at their source.

Ensuring protective sleeves are integrated onto your machine’s hydraulic hoses can prevent damage to the machine and injury to the operator. To test the Diamondback sleeve’s durability and strength against pinhole leaks, a series of tests were run that simulated different levels of protection, from a bare line with no protection, to the Diamondback PRO sleeve.

Tested for pinhole protection up to 4000 PSI and burst protection up to 12000 PSI, Diamondback is made from a proprietary engineered fiber woven tightly and heat-treated, which shrinks the sleeve to the finished dimension. The weave produces a very sleek finish allowing Diamondback to easily slide over hoses and hose ends without snagging.

BUILT TO LAST; BUILT FOR YOUR NEEDS

The Diamondback sleeve is convenient to use with its unmatched flexibility and UV and chemical resistance. The UV protection that Diamondback offers rivals that of automotive seat belt specs which are considered to be the best on the market.

Diamondback vs Competitor Sleeves

Both are high temperature resistant with rating of 200F continuous exposure and 350F intermittent exposure.

Diamondback and Diamondback PRO both boast excellent abrasion resistance and are tested to over 1.7 million abrasion cycles making the sleeves ideal for many applications and industries.

Often used in construction, agriculture, and concrete applications, Diamondback sleeve is manufactured in numerous sizes, ranging from 17mm to 146mm.

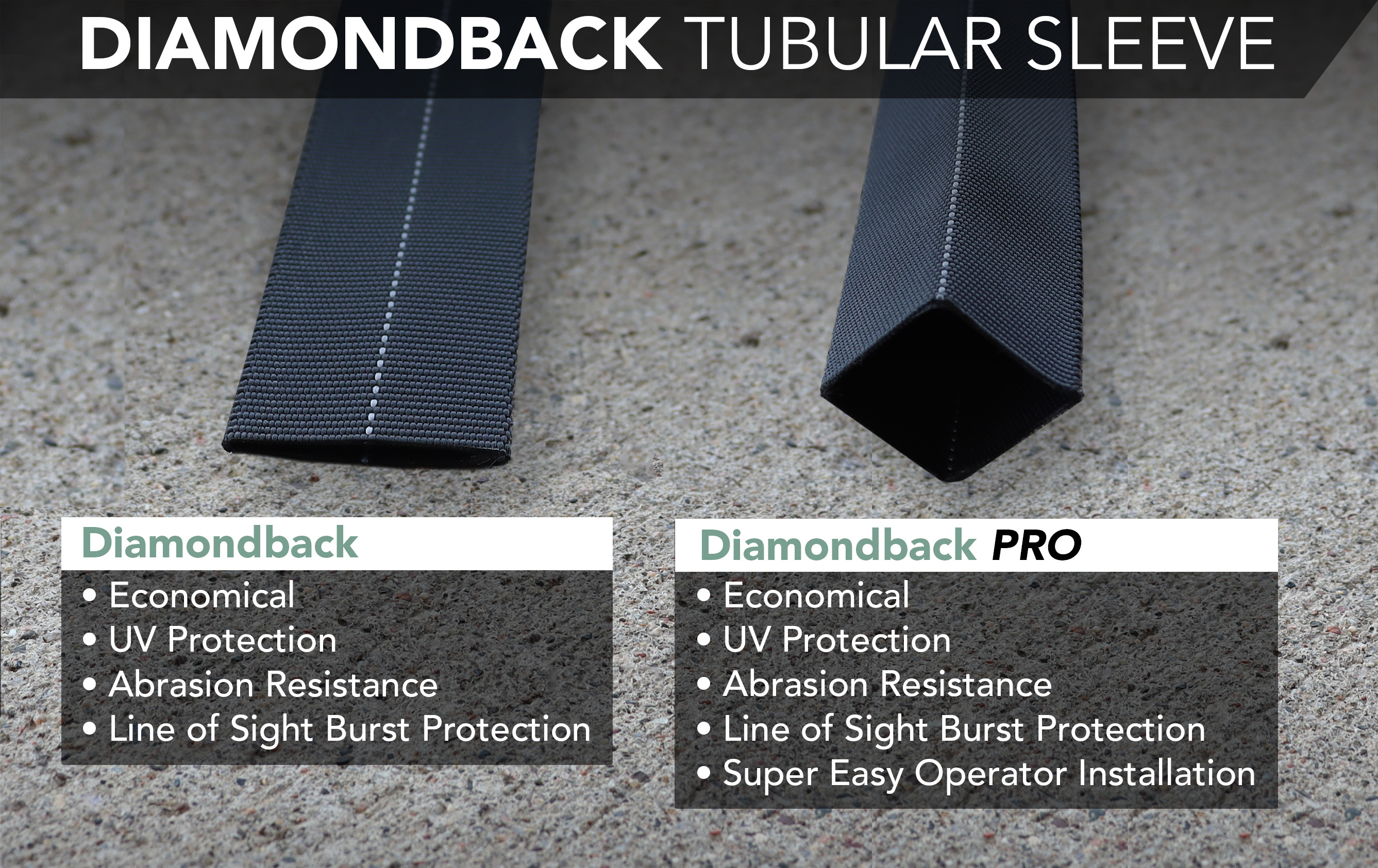

THE DIFFERENCE BETWEEN DIAMONDBACK AND DIAMONDBACK PRO

Woven from the same raw material, the sleeves are heat treated to hold their integrity during harsh working environments. The difference however, is the Diamondback PRO sleeve has a proprietary weave to hold an open diamond shape; putting the diamondback in “Diamondback PRO”. This feature greatly reduces the install time by up to 80%.

| Diamondback | Diamondback PRO |

| Line-of-sight operator protection | Line-of-sight operator protection |

| Abrasion resistant | Abrasion resistant |

| High temperature tested | High temperature tested |

| Contains pinhole leaks | Contains pinhole leaks |

| UV & chemical protection | UV & chemical protection |

| Unmatched flexibility | Unmatched flexibility |

| Exceeds industry standard regulations | Exceeds industry standard regulations |

| Economical | Economical |

| Pinhole protection tested to 4000 PSI | Pinhole protection tested to 4000 PSI |

| Burst protection tested to 12000 PSI | Burst protection tested to 12000 PSI |

| Saves up to 80% on sleeve installation |

EASY INSTALLATION

The Diamondback PRO unique diamond sleeve shape aids in installation and can reduce installation costs by 80%. Diamondback PRO allows a single assembler to easily install long lengths of sleeve in a fraction of the time it currently takes, greatly reducing or eliminating the fatigue that assemblers experience and allowing for far more consistent production throughout an eight-hour shift.

The PRO series not only increases production, but also increases the profitability of the assembly operation by reducing the labor involved in sleeve assembly. Don’t just take our word for it! Request a sample sleeve to try it for yourself.