3 min read

Industrial Textile Types: Comprehensive Selection Guide

Python Covers Team

:

Nov 18, 2025 9:19:02 AM

Have you ever searched for a specific solution to improve durability and functionality on your job site, but come up with dead ends? Maybe it's a specific size of protective wrap for a cable, or a unique catcher on hay merger. Industrial textiles may be the unsung heroes of high-performance manufacturing that you're looking for.

Industrial textiles are fabrics engineered for function and performance. These advanced fabric technologies can be custom designed to fit your exact needs for each job site, creating opportunities for everything from building straps to heated covers to protective sleeving.

In this article, we'll explore the various industrial textile types to choose from and provide application-specific design guidelines.

What are Industrial Textiles?

Industrial textiles are a custom manufactured type of technical textile designed to meet requirements in durability, flexibility, and functionality for extreme work environments. In other words, technical textiles are a broader, all-encompassing category of fabrics made for high-performance, non-decorative intentions, while industrial textiles are a specific type - commonly used in manufacturing and industrial applications.

The properties of industrial textiles vary depending on the specific application they're designed to meet. The most common properties of industrial textiles include:

- Abrasion resistance

- Chemical resistance

- Flexibility

- Spark protection

- Puncture resistance

- Non-wicking ability

- Temperature rating

- UV protection

Type of Industrial Textiles

A wide range of fabric options is available for developing a custom industrial textile design. As fabric choices continue to evolve, they're reshaping the way manufacturers approach industrial textile design.

Industrial applications increasingly depend on custom textile manufacturing, driven by ongoing innovations in the field. Popular enhancements include specialized coatings that boost resistance to hear, moisture, and chemicals; antimicrobial treatments for healthcare settings; and reflective materials for increased safety.

Some of the commonly used industrial textiles include:

- Woven

- Nonwoven

- Knitted

- Coated and laminated

- Advanced composites

Woven

Woven fabrics are created by interlacing threads together, creating a tight-knit grid. They offer durability and value with their affordability and long-lasting performance. Woven fabrics are best known for their stability, strength, and resistance to abrasion, which limits the stretchiness.

Common applications include industrial belts, conveyor systems, and protective gear for outdoor and safety use.

Nonwoven

Nonwoven textiles are made of fibers bonded by mechanical, thermal, or chemical processes. They are very lightweight and cost-effective, but are less durable than other textiles, like woven ones.

Examples of applications include HVAC filters, heat shields in cars, and cable insulation.

Knitted

Because knitted fabrics are made of interwoven yarns, they are best known for their stretch, breathability, and flexibility. However, they have lower durability and often snag and lose their shape.

Common applications include automotive interiors and sportswear.

Coated and Laminated

Coated fabrics can be made by adding a liquid polymer to the surface of a woven, nonwoven, or knit textile. This makes the textile waterproof, chemical-resistant, or UV-resistant. Examples include parachutes and escape slides for aircraft.

Laminated fabrics are created when two or more materials are bonded using an adhesive or heat. The materials often include a fabric adhered to a film or foam. Common products with laminated fabrics include industrial curtains and tarps.

Advanced Composites

Advanced textile composites weave together fibrous textiles (like cotton or nylon) with a matrix material (often a polymer) that binds the fibers together. This creates a stronger, but lighter material. The multiple layers enhance resistance to moisture, UV rays, and flames.

Manufacturing costs for advanced composites can be higher compared to other textiles. These sturdy textiles are commonly used for military equipment, in the aerospace industry, and as ship covers.

How to Choose the Right Industrial Textile for Your Application

Once you finalize your design, determine which textile suits your specific application. Key factors to consider while reviewing potential fabrics include:

Performance requirements: What does the textile have to withstand? Consider whether it will be exposed to immense force, moisture, or flames.

Environmental exposure: Is your worksite indoors or outdoors? Consider factors like temperature, weather exposure, and UV light. These can all contribute to significant wear and tear over time.

Regulatory standards: Know the regulations that apply in your industry. Is the fabric required to hold a specific certification to ensure safety and quality standards?

Cost and longevity: While lower-cost textiles may be appealing, also consider the return on investment. Paying more up front could result in long-term savings.

Industry-Specific Applications

Textile manufacturers can engineer them to meet specific demands in many different environments, including protecting marine equipment.

The table below highlights the range of industries that rely on customized industrial textiles, featuring examples of fabric types from the Python catalog. We’ve also included real-world examples and key benefits that demonstrate why each textile is an ideal fit for that environment.

| Industry | Textile | Use Case | Benefits |

|---|---|---|---|

|

Agriculture & Farming

|

5601 sleeve, 1050B sleeve, and PVC-coated sleeve

|

Hay & forage netting, crop sprayers, planters

|

Resistant to abrasion and harsh outdoor conditions, including sunlight, moisture, and fluctuating temperatures

|

|

Industrial Equipment & Manufacturing

|

Signal sleeve, Black Poly sleeve, Weld Armor sleeves

|

Robotics, automation, CNC machining, welding

|

Resistant to abrasion, chemicals, and extreme temperatures; shield from dust, debris, and moisture

|

|

Recreational Sports

|

PVC-coated fabric

|

Ice fishing |

Resistant to UV, water, and abrasion

|

|

Military & Tactical Gear

|

1050B fabric, 18411 sleeve

|

U-joint cover for aircraft elevator system on Naval ships, welding

|

Resistant to extreme conditions, abrasions, and impact, easy to remove for maintenance

|

|

Safety & Thermal

|

Fire sleeve, Radiant liner, Diamondback sleeve

|

Muffler covers, spray foam, VAC, natural gas

|

Resistant to fire, thermal retention, and operator safety

|

Custom Sewing and Design Solutions

If you can’t find your desired solution for your specific needs, it may be time to consider custom sewing with high-performance textiles. Custom textile manufacturing creates the solution you need for your job sites, all while enhancing strength and protection.

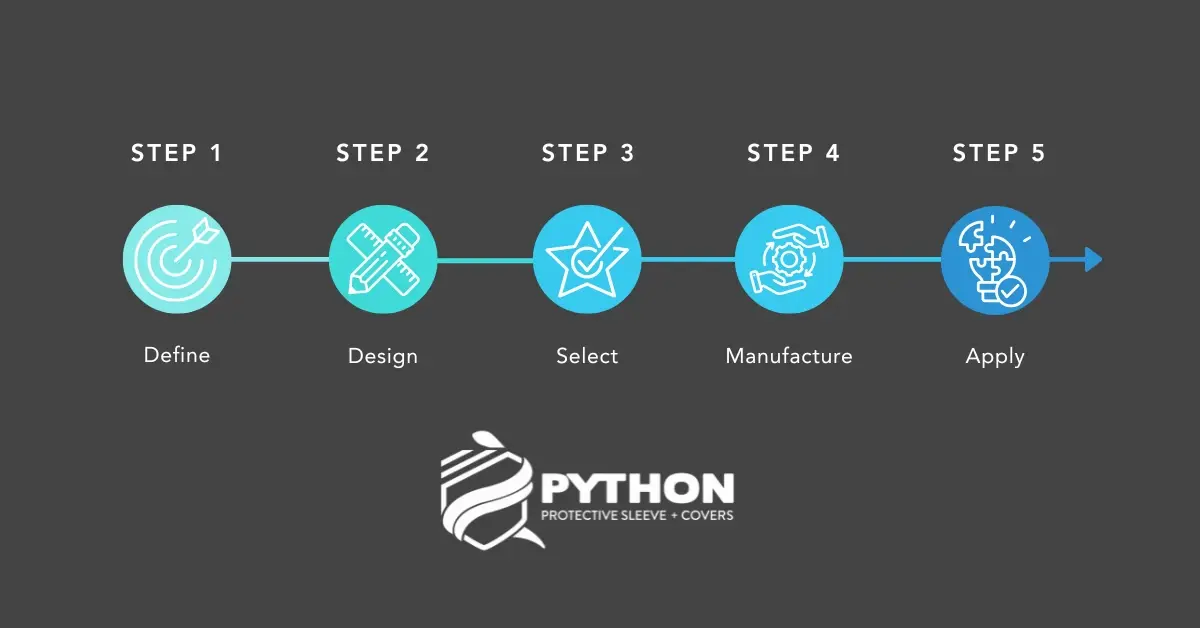

Partnering with a trusted custom manufacturer ensures the textiles are made from high-quality materials while meeting performance expectations, as well as industry standards. Download Python’s FREE e-book and discover the possibilities of custom textile manufacturing.

Let's chat so we can make a custom solution perfectly fit for you.