3 min read

Checklist: Providing Clean Dry Air in a Machine Shop

Tsunami Team

:

Feb 20, 2023 11:15:22 AM

From choosing a compressor to remembering to set up a regular maintenance schedule, the process of providing dry air in a machine shop takes thought and planning.

Ignoring regular maintenance efforts leads to a hit to your wallet – sooner, rather than later. Setting up the system to provide access for that maintenance means less hassle in the long run.

To that end, we’ve developed a recommended maintenance checklist to keep your compressed air system in working order.

Maintenance Checklist for Providing Dry Air in a Machine Shop

Planning the layout and providing dry air in a machine shop effectively can be broken down into several steps.

The process involves careful consideration of the components, as well as the location of the air intake and exhaust.

Download the Compressor Maintenance Checklist:

- Compressor

-

-

Ventilation: Ventilation for the compressor room should include an intake that is low to the ground and a vent to the outside when possible.*

-

Intake Location: Air intakes should be located away from exhaust vents or other high-contaminant areas. Loading bays, for example, can cause an increase in particulate matter in the air due to constant opening and closing of overhead doors.

-

Storage Drain Maintenance: Make sure storage tanks have automatic drains. These need to be checked regularly to ensure they are operating correctly and effectively.

-

| *Note: There is an exception worth considering for those located in cold weather climates, dual vent controls. Venting the hot air into the facility helps save on heating costs during the winter months and vent to the outside in summer months to minimize shop temperatures. |

- System Components

-

-

Type of Dryer: Consider compressor compatibility, moisture tolerance, and pressure to determine the optimal air needed for specific applications. Learn the difference between regenerative and refrigerant dryers.

-

Number of dryers: A thorough investigation into your equipment and the specific air quality for each piece will determine not only the number of dryers you should install but also what technology is best for your specific needs. In some instances, having a single, large dryer may seem the most effective route, some applications may require more effective dryer technology to provide extremely low dew points. In these instances, rather than installing a large regenerative dryer, you may consider utilizing smaller, point of use dryers to these targeted areas for low dew points only; this will save on overall energy costs and possible lower up-front investments.

-

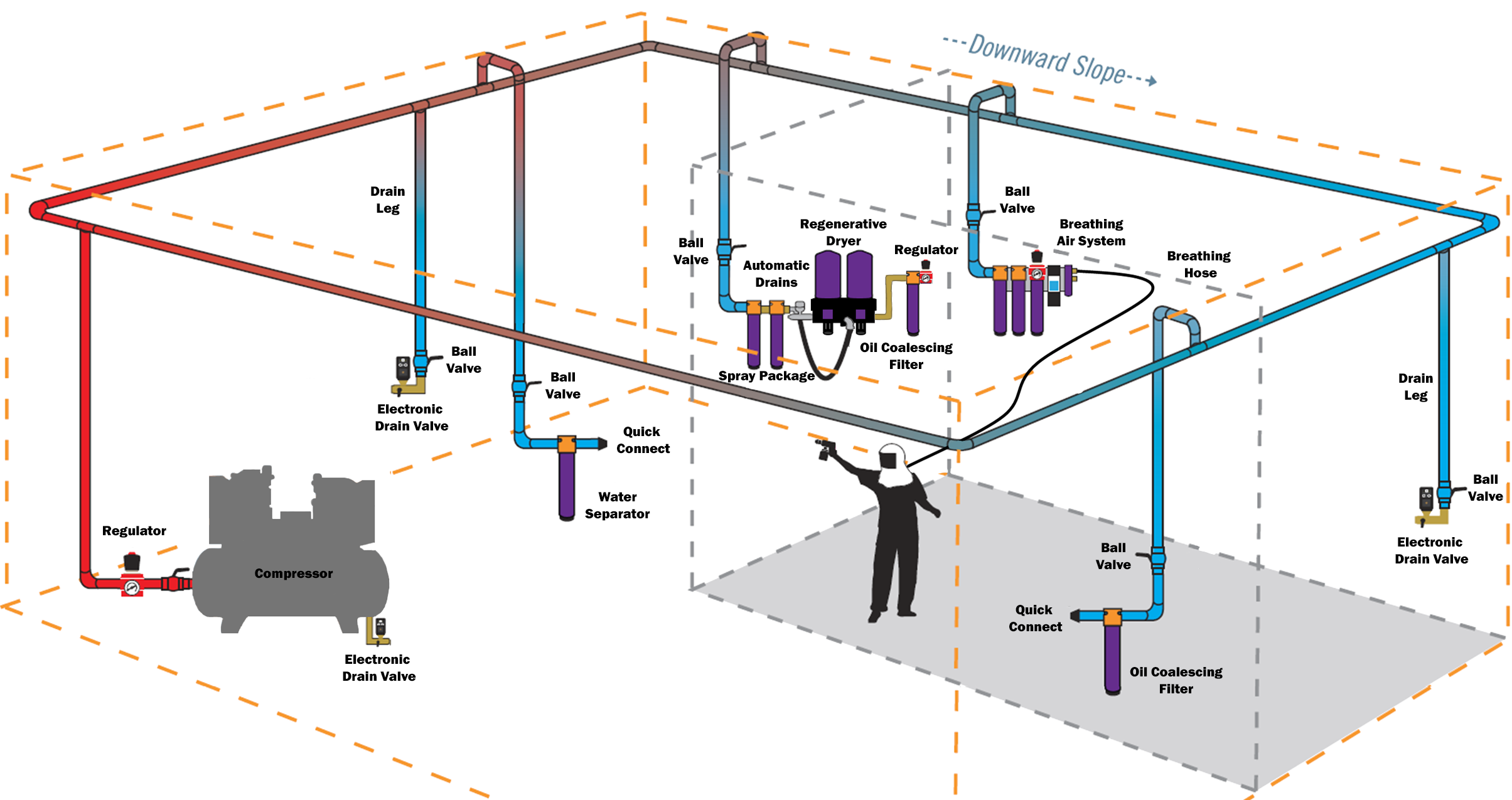

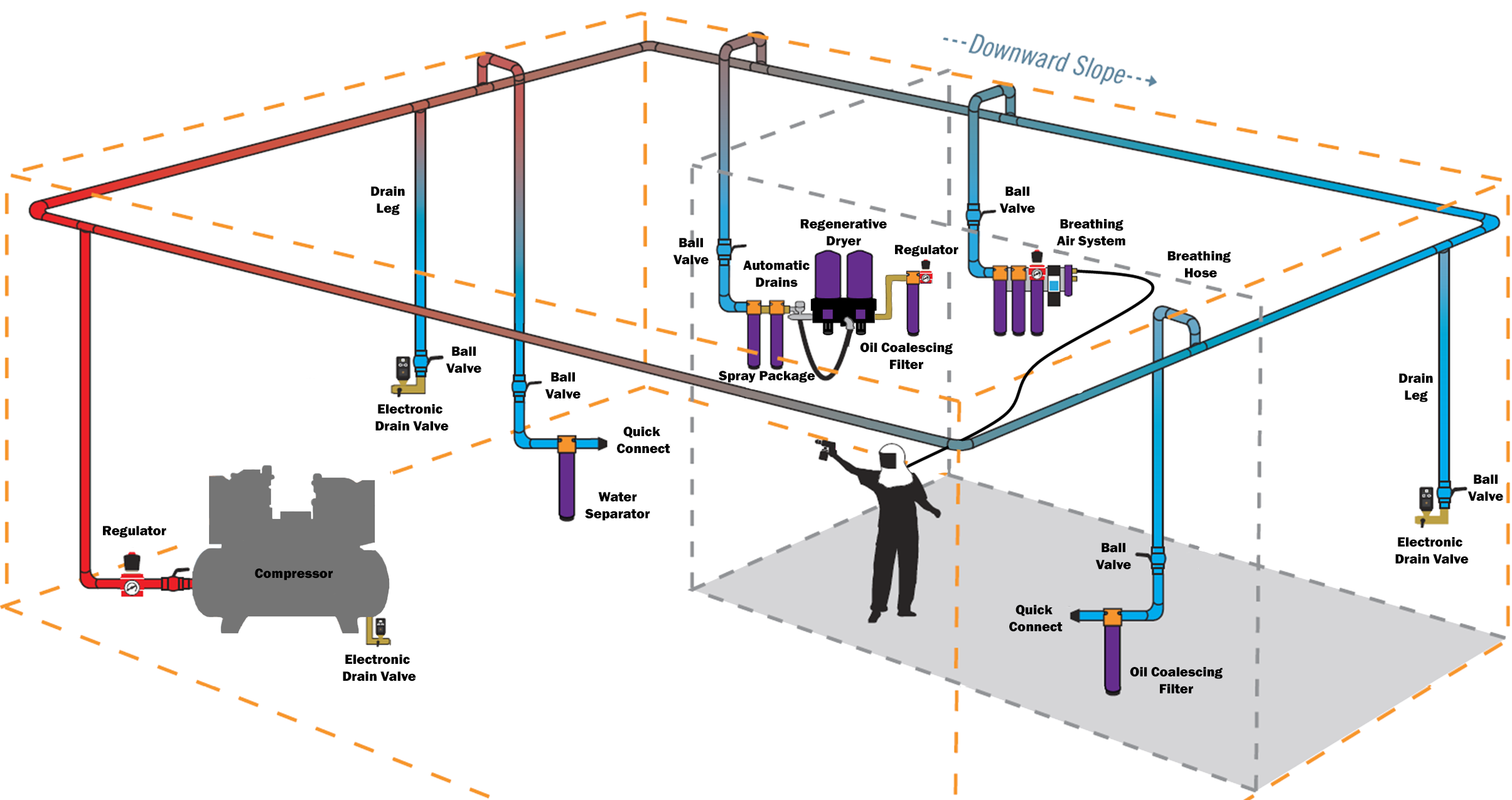

Filtration: Filters should be placed within 3 to 10 feet of the machine utilizing the compressed air. This maximizes the filtering impact and provides the cleanest air quality where it is needed. Learn how to to install a water separator filter and oil coalescing filter.

-

Storage tanks: Providing dry air in a machine shop means having sufficient volume to supply the applications requiring clean, dry air. Larger tanks provide the benefits of cutting down on both electricity usage and heat generation.

-

Regulator: Store air at a higher pressure rather than operate the entire system at that pressure. This reduces wear and tear on the system as it constantly turns on and off to maintain higher pressure throughout.

-

Piping: Large-diameter piping enhances efforts to maintain consistent volume and pressure in the system, minimizing pressure drop.

-

- Layout

-

-

Distribution: Your piping layout is crucial to effective and efficient compressed air distribution; be sure to use larger pipe diameters for main line and always design your piping in a looped system. Avoid “dead ends”.

-

Slope: When installing your pipe, be certain to slope your pipe away from your compressor; a good rule of thumb, 1” down slope for every 10 - 15ft of pipe.

-

Drip legs: be sure to factor in drip legs throughout your system. Effective placement of drip legs will capture moisture and debris; drain them automatically or set up routine inspections.

-

Riser pipe: For all your air drops, utilizing effective “riser” piping can help eliminate contamination from reaching your point of use connection. Effective risers extend upwards from main pipe 5-6” before you jog over and then downward.

-

Tank Drain - An automatic tank drain helps reduce corrosion and improve system efficiency by maximizing your tank storage volume.

-

- Maintenance

-

-

Schedule - Plan on weekly maintenance for heat exchangers and assign someone to regularly check filters and automatic tank drains.

-

Pressure Control - Consider dropping your system’s pressure from 120 psi to 100 psi. You could save over $10,000 in a year’s time.

-

Fix leaks - This is where the most money is saved and can make the difference in the size of compressor needed. The Department of Energy estimates that over 30% of all compressed air generated is lost through air leaks.

-

Make a Plan and Don’t Forget the Maintenance

Providing clean dry air in a machine shop can eliminate downtime and provide a high quality finished product.To maintain a system that provides compressed air to meet your specific needs, the system must include the proper components, be laid out effectively, and be maintained. The right planning now can mean smoother sailing down the road.

Discuss your Options with an Expert

Tsunami’s compressed air experts are available to discuss how to provide clean dry air in your application. Reach out to your compressor manufacturer for detailed maintenance recommendations for your specific compressor. When it comes to methods for drying compressed air, the process requires attention well beyond the installation. You can also check out our preventative maintenance checklist to think proactively.

Download the Compressor maintenance Checklist now!