4 min read

Understanding C1D1 Hazardous Environment Requirements and Meeting Them

Tsunami Team

:

Sep 3, 2025 8:00:00 AM

In your working environment, even a single spark or small leak could endanger lives.

Class 1 Division 1 (C1D1) refers to working environments in industrial settings where flammable gases, vapors, or liquids are present. The C1 designation classifies environments where volatile substances are present, and the D1 indicates these substances are present during regular operations. Therefore, there are specific C1D1 safety standards that companies with hazardous environments - such as oil and gas refineries, chemical plants, and paint facilities - must follow. These ensure that equipment and protocols meet certain safety standards to help prevent catastrophic events.

In this article, we’ll cover C1D1 standards, the agencies that mandate them, and why it’s important to understand these standards when working in a hazardous environment. We’ll also explore filtering and drying products available that prioritize safety.

C1D1 Requirements and Regulations

C1D1 environments have unique hazards that demand strict regulatory compliance. There are official groups in place that regulate these requirements. Manufacturers working in C1D1 environments must have equipment that meets key safety standards, as well as carry C1D1 certifications. These regulations typically involve:

C1D1 Safety Requirements for Equipment

C1D1 environments mandate equipment specifically designed to prevent ignition and contain any potential hazards. These safety standards keep organizations in compliance, but most importantly, keep your end user safe.

Key safety requirements for C1D1 products and equipment include:

- Explosion-proof equipment: This equipment is made to contain any blast, spark, or heat from escaping the device. They’re also resistant to dust and moisture. Any equipment used in C1D1 environments must undergo intense testing mandated by certified agencies.

- Ventilation and detection systems: These are a must in C1D1 areas due to the high risk of explosions. These systems work together to eliminate hazardous gases in working environments and alert workers to dangerous concentrations.

- Proper installation and maintenance: Installation of equipment, electrical devices, etc., must be done by a professional. All installations need to follow the strict guidelines set by the NEC. Regular maintenance and inspections are required, too, for the equipment to ensure the safest environment possible.

C1D1 Governing Agencies

Many agencies oversee the safety standards for C1D1 environments. They each play a critical role in mandating that the working conditions, equipment, and installations are all following each of their strict safety standards. Some of these organizations include:

- The National Electrical Code (NEC): C1D1 was born from NEC’s hazardous location classification system. NEC sets the standard for the safe installation of electrical wiring and equipment. It’s important to note that the NEC is not a U.S. law but is usually mandated by state or local law.

- Occupational Safety and Health Standards (OSHA): This agency covers the requirements for the electrical equipment and wiring in C1D1 locations.

- National Fire Protection Association (NFPA): A global, nonprofit organization that develops and enacts codes and standards related to fire, electrical, and building safety.

.webp?width=1200&height=200&name=OSHA%20(without%20saying%20OSHA).webp)

C1D1 Equipment Certifications

Equipment in C1D1 areas must be certified by certain agencies to prove it’s safe to run during such dangerous conditions. These certifications prove that the equipment has passed testing to verify it’s suitable for use in hazardous environments.

C1D1 certifications include:

- Underwriters Laboratories (UL) and Canadian Standards Association (CSA): Agencies that certify equipment and products for hazardous locations, including C1D1 environments.

- NFPA 70: A code enforced in all 50 states and regulated by the NFPA. This code ensures safe electrical design, installation, and inspection in hazardous work zones.

- ATEX: A European certification for equipment safe to use in areas with flammable gases, vapors, and dust.

Why is C1D1 Compliance Critical?

C1D1 compliance is critical to maintaining a safe workspace for employees. Following the guidelines for C1D1 safety helps you achieve the following goals:

- Protects employees: Following strict guidelines ensures a safer workplace for your employees. It’s already a dangerous work environment – your workforce should be guaranteed a workplace that’s doing everything possible to keep them safe.

- Protects assets: These rigorous guidelines help protect the equipment, facilities, and surrounding property, preventing any ignitions and sparks that could destroy expensive equipment.

- Meets regulatory requirements: Staying compliant helps you avoid any fines, shutdowns, and legal liabilities in the event of an accident. Penalty amounts can range significantly depending on the severity of the violation, the size of the business, and prior offenses. For example, OSHA penalties can range from $16,550 to $165,514 per violation.

- Increases efficiency: Using C1D1 certified equipment reduces downtime and breakdowns because of its durability.

C1D1 Compliant Solutions

So, what’s a maintenance manager to do in the face of all these threats and regulations?

In the world of C1D1, if you take care of the working environment, the environment will take care of your equipment. For example, the air supply itself is a critical factor in C1D1 workspaces. Compressed air is often used in these environments to power pneumatic tools, actuators, or instruments. If the air carries any debris - oil, water vapor, or particulate matter - it can compromise equipment. Or worst yet, lead to explosion risks.

With this very risky environment, reliable equipment and pneumatic supply are non-negotiable. Contaminated air could lead to malfunctions. Proper drying and filtering not only extend the life of your machines but also provides a safe workplace.

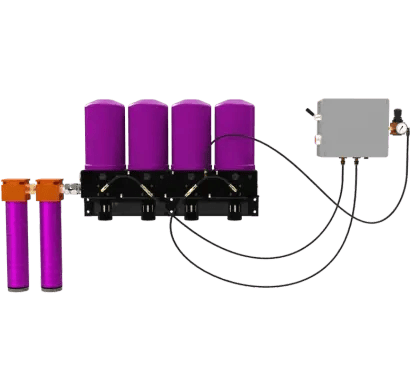

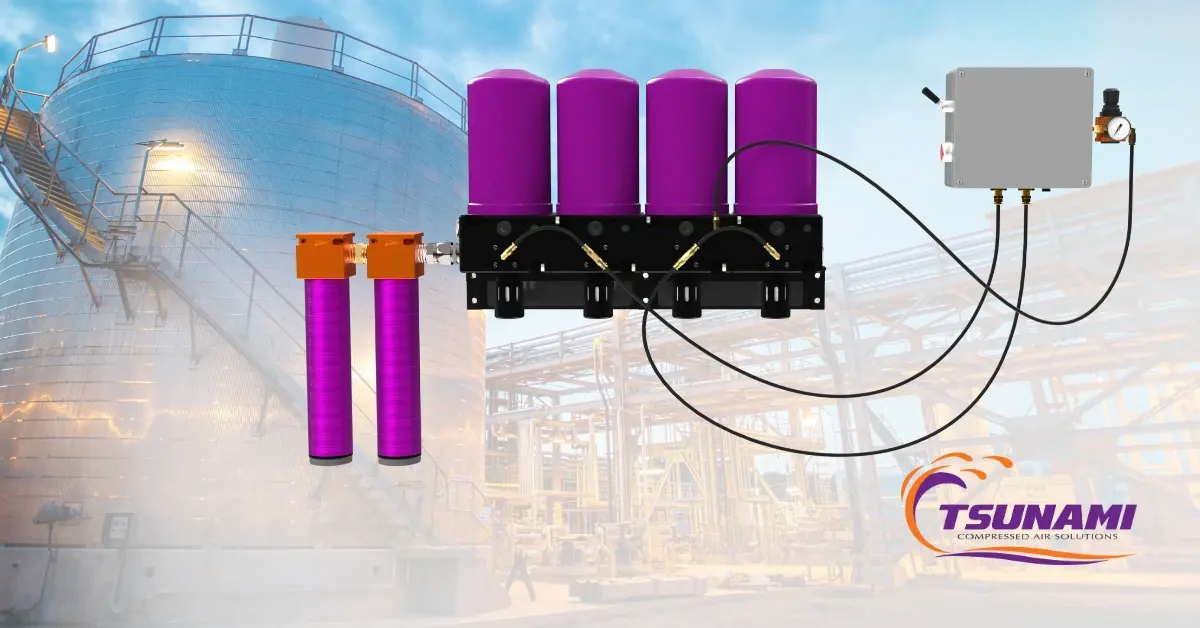

One emerging solution is using a pneumatic air dryer to meet C1D1 hazardous environment requirements. The right one can provide safe and reliable compressed air drying without the use of electricity.

Advanced pneumatic air dryers come armed with several key features that enhance C1D1 safety. Look for these ones in particular:

- Pneumatic-powered controller: The system runs without electricity, decreasing the risk of ignition in hazardous environments.

- Water separator and oil coalescing filter: These filters work together to make sure the air is free of moisture and oil.

- Regenerative dryer: Removes moisture from compressed air, lowering the dew point so that condensation and freezing can’t occur in the pipes.

- Mounting options: The air dryer can be mounted on the wall or the floor, making it easy to fit into the existing layout of your facility.

- Float drains or pneumatic drains for filters: Once the contaminants are caught, they’re disposed of properly by these drains.

A wide range of industries rely on the pneumatic air dryer to minimize risks by ensuring clean, dry air in hazardous environments.

Engineering Safety for C1D1 Operations

It’s critical to maintain safety in any work environment with a C1D1 classification. Innovative engineering and adherence to these standards will demonstrate your commitment to delivering reliable, safety-focused solutions.

Tsunami products are designed to perform under the most demanding conditions. Our innovative engineering solutions combine with the strict C1D1 guidelines to meet the rigorous standards. Learn how our Pneumatic Air Dryers can help deliver the safest work environment and provide peace of mind in these high-risk industries.

To learn more about the Tsunami C1D1 Pneumatic Air Dryer or safety tips, contact your Tsunami sales representative.