Your Hydraulic Hose Protection Sleeve Choice

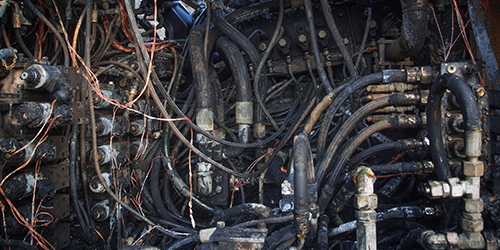

Hydraulic hoses are exposed to a lot of wear and tear, which can cause them to break faster than expected. Not only does this require costly repairs, but it can also be dangerous. Using the right protective sleeve is essential for maintaining the integrity of hydraulic hose systems.

Python’s Diamondback Abrasion Sleeves provide the perfect solution for extending the lifespan of hydraulic hoses by providing protection from wear and tear while also being easy to install. With these sleeves, you no longer need to worry about expensive repairs or dangerous breaks in your hydraulic hoses.

This resource will walk you through the causes of pinhole leaks, protection options, and the benefits of choosing Diamondback products.

Too Busy to Read Now? Take this Resource with you

3 COMMON CAUSES OF PINHOLE LEAKS, BURSTS & THEIR SOLUTIONS

While there are many situations that can cause a pinhole leak or hose burst, there are three common causes:

Abrasion occurs when a hydraulic hose rubs, expands and contracts against the machine during operation as the pressure changes within the hose.

Effect: This repeated contact causes the outer layers of the hose to slowly deteriorate, weakening it and eventually resulting in a leak or burst.

Solution: Make sure the hose is not in contact with any surfaces and equip it with a protective cover.

When hoses are exposed to high temperatures, they begin to lose their flexibility, stiffen, and crack.

Effect: As time goes by, hose cracks may eventually reach the outside of the hose, causing bursts or pinhole leaks.

Solution: Install a heat-resistant sleeve around the hose. In addition, inspect the hose for proper assembly and the appropriate amount of fluid.

When routed through a highly-abrasive area, such as next to the engine compartment, the hose is exposed to additional wear and tear.

Effect: Incorrectly routed hydraulic hose systems face a number of issues, including surface damage, bends, rubbing, and kinks.

Solution: Reroute hoses away from an abrasive area, pivot point, or high-temperature environment.

*The best hydraulic hose protection sleeves meet ISO 6945 and ASTM D6770 and are tested to provide next-level abrasion protection for more than 1 million cycles. Also, it is crucial to pay close attention and ensure the minimum bend radius is met to avoid failure.

3 LEVELS OF PROTECTION FOR OEMS

At a base level, understanding how hydraulic systems fail under pressure is important to select the correct level of protection. Typically, hydraulic hoses fail due to one of three main reasons:

0

Hydraulic fluid operating at unsafe temperatures or pressures.

0

The hydraulic lines are the wrong size or were installed or assembled incorrectly.

0

Extreme ambient conditions include vibration, abrasion, extreme temperatures, volatile/harsh chemicals, damaging UV rays, and more.

Depending on the use of the equipment in question, as well as the end-users budget, different levels of protection can be added on during the manufacturing phase and when routine maintenance is performed.

Let’s break down these levels in detail and discuss their benefits and optimal operating environments:

- Good: Diamondback LITE

- Better: Diamondback Line- of-Sight

- Best: Diamondback PRO

DIAMONDBACK LITE SLEEVES ARE GOOD:

The Diamondback Tubular Sleeve is a “good” option for basic hose protection, abrasion resistance and UV degradation. Often used in agriculture, construction, and mobile equipment applications, Diamondback Lite is made from a proprietary engineered fiber woven tightly and heat-treated, which shrinks the sleeve to the finished dimension.

Key Features of DBK LTE includes:

- Tested over 40,000 abrasion cycles (ISO 6945)

- Temperature tested to 200°F continuous, 350°F intermittent

- Easy install; Cut to length with a scissors

- Mine Safety and Health Administration (MSHA) approved

- Meets conductivity standard ISO 8031

- Unmatched UV Protection

DIAMONDBACK LINE-OF-SIGHT SLEEVES ARE BETTER:

The Diamondback Tubular Sleeve offers dual uses by providing line-of-sight operator protection from hydraulic hose failure and abrasion resistance. Often used in construction applications, Diamondback is made from a proprietary engineered fiber woven tightly and heat-treated, which shrinks the sleeve to the finished dimension. The Diamondback Sleeve meets the EU Machinery Directive 2006/42/EC as well as the NSW "Guideline for Fluid Power System Safety at Mines."

Key Features of DBK LOS Sleeves include:

- Highly abrasion-resistant material tested over 1.7 million abrasion cycles (ISO 6945)

- Meets “Line of Sight” operator protection specification EN982, ISO Norm 833, EN414, ISO Regulation 3457:2003(9.1)

- Pinhole protection tested to 4,000 PSI

- Burst protection Tested to 12,000 PSI

- Mine Safety and Health Administration (MSHA) approved IC-289/01

- Meets conductivity standard ISO 8031

DIAMONDBACK PRO SLEEVES ARE BEST FOR OEM APPLICATIONS:

For easy installation, burst protection, pinhole leaks, and more, the Python Diamondback PRO Tubular sleeve offers the best level of operator protection from hydraulic hose failure. Often used in construction applications, Diamondback is made from a proprietary engineered fiber woven tightly and heat-treated.

The Diamondback PRO hydraulic hose protective sleeve offers unmatched pin-hole and burst protection, and top-of-the-line models. It meets the “line-of-site” operator protection specifications, while also featuring easy installation.

Key Features of the Diamondback PRO Sleeve includes:

- Highly abrasion-resistant material tested over 1.7 million abrasion cycles (ISO 6945)

- Meets “Line of Sight” operator protection specification EN982, ISO Norm 833, EN414, ISO Regulation 3457:2003(9.1)

- Pinhole protection tested to 4,000 PSI

- Burst protection Tested to 12,000 PSI

- Mine Safety and Health Administration (MSHA) approved IC-289/01

- Meets conductivity standard ISO 8031

- Proprietary weave reduces installation time by up to 80%

It’s evident that no matter what environment the machine will operate in, or the budget of the end-user, integrating HH protective sheaths is a surefire way to not only maximize the lifespan of the equipment but also to ensure operator safety.

DIAMONDBACK AND DIAMONDBACK PRO | INDUSTRY SAFETY LEADERS

Both Diamondback and Diamondback PRO meet industry regulated standards:

“Line of Sight” operator protection specification EN982, EN414, EN ISO Regulation 3457:2008

Conductivity standard ISO 8031

Mine Safety and Health Administration (MSHA) approved IC-289/01

EU Machinery Directive 2006/42/EC

NSW “Guideline for Fluid Power System Safety at Mines”

.jpg)

PINHOLE AND BURST PROTECTION

Hydraulic hose pinhole leaks act much like a hypodermic needle, piercing the skin and injecting hydraulic fluid into nearby people. The Diamondback tubular sleeve prevents such injuries from ever taking place by stopping pinhole leaks and bursts at their source.

Ensuring protective sleeves are integrated onto your machine’s hydraulic hoses can prevent damage to the machine and injury to the operator. To test the Diamondback sleeve’s durability and strength against pinhole leaks, a series of tests were run that simulated different levels of protection, from a bare line with no protection, to the Diamondback PRO sleeve.

BUILT TO LAST; BUILT FOR YOUR NEEDS

The Diamondback sleeve is convenient to use with its unmatched flexibility and UV and chemical resistance. The UV protection that Diamondback offers rivals that of automotive seat belt specs which are considered to be the best on the market.

Woven from the same raw material, the sleeves are heat treated to hold their integrity during harsh working environments. The difference however, is the Diamondback PRO sleeve has a proprietary weave to hold an open diamond shape; putting the diamondback in “Diamondback PRO”. This feature greatly reduces the install time by up to 80%.

WHAT'S THE DIFFERENCE?

Diamondback Lite offers hose abrasion and UV resistance. Diamondback Line-of-Sight and Diamondback PRO provide operator protection in addition to unmatched UV and abrasion resistance.

| Diamondback LTE | Diamondback LOS | Diamondback PRO |

|---|---|---|

Economical Abrasion Sleeve |

Line-of-Sight operator protection |

Line-of-Sight operator protection |

Abrasion Resistant 40,000+ abrasion cycles |

Abrasion Resistant 1.7 million abrasion cycles |

Abrasion Resistant 1.7 million abrasion cycles |

High temperature tested (200°F) |

High temperature tested (200°F) |

High temperature tested (200°F) |

Does NOT contain pinhole leaks |

Pinhole leak containment |

Pinhole leak containment |

UV & chemical protection |

UV & chemical protection |

UV & chemical protection |

Unmatched flexibility |

Unmatched flexibility |

Unmatched flexibility |

Meets “Line of Sight” industry standard regulations |

Meets “Line of Sight” industry standard regulations |

|

Pinhole protection tested to 4000 PSI |

Pinhole protection tested to 4000 PSI |

|

Burst protection tested to 12000 PSI |

Burst protection tested to 12000 PSI |

|

Saves up to 80% on sleeve installation |

EASY INSTALLATION

The Diamondback PRO unique diamond sleeve shape aids in installation and can reduce installation costs by 80%. Diamondback PRO allows a single assembler to easily install long lengths of sleeve in a fraction of the time it currently takes, greatly reducing or eliminating the fatigue that assemblers experience and allowing for far more consistent production throughout an eight-hour shift.

5 REASONS DIAMONDBACK IS THE PROTECTION SLEEVE FOR YOUR HYDRAULIC HOSE

Without a protective sleeve, the life of hydraulic hoses can be shortened dramatically. However, it is important to remember that span decreases significantly with consistent exposure to weather, abrasive surfaces, and other external factors. Agriculture, construction sites, and mobile equipment are all areas where the Diamondback Sleeve provides reliable operation.

When outfitted with a protective sleeve, a hydraulic hose can last longer, as exposure to abrasion and various other impediments is reduced.

Diamondback Sleeves are designed to help you get the most from your hydraulic hoses by providing hose protection:

UV Protection

Continued exposure to the sun weakens hydraulic hoses, leaving them brittle and prone to leaks or bursts.

Abrasion Resistance

Diamondback Sleeves provide abrasion resistance to help reduce the effects of environmental conditions.

Lightweight

Heavy hoses can significantly impact equipment performance by weighing down the machinery and causing pressure on connections.

Flexible

Diamondback Sleeves are flexible and move with the hose, creating less strain on the line while providing protection.

Professional Look

The Diamondback Sleeves provide a cleaner look while protecting the hydraulic hose.

LINE OF SIGHT TESTING OF HYDRAULIC HOSES WITH PINHOLE FAILURES

Whether the equipment is operating on a farm, in a mine, or at a construction site, ensuring operator and passerby safety is of paramount importance when hydraulic equipment is present and in operation.

Pinhole leaks, or failure of a pressurized hose in any way, may cause severe injury, or potentially even death if left untreated.

To test the Diamondback sleeve’s durability and strength against pinhole leaks, a series of tests were run that simulated different levels of protection, from a bare line with no protection, to the ultimate Diamondback Pro sleeve.

The tests, shown in the video below, were completed using a series of highly-pressurized hydraulic lines (tested above 4,000 PSI), some of which had no sleeves, some had competitive sleeves, and some had the Diamondback Pro. The test was completed using an uncooked bratwurst to simulate the impact a pinhole leak can have on an operator’s hand or limb.

get started with diamondback today

Diamondback and Diamondback Pro provide the ideal solution for improving the hydraulic hose lifespan. These sleeves remove the need to worry about expensive repairs or dangerous breaks in your hydraulic hoses, thereby improving safety for operators and bystanders alike.

Contact Us