4 min read

Your Welding Cable Needs Protection Against These 6 Hazards

Python Covers Team

:

Aug 22, 2025 9:00:00 AM

In industrial and construction settings, damaged equipment and unexpected downtime can quickly halt operations and increase costs. Welding cables are vital in these settings for productivity but are especially vulnerable.

Using protection for your cables keeps your employees safe, makes production more efficient, and helps maintain a longer lifespan for equipment. In this article, we’ll cover the common risks that threaten welding cables, as well as solutions for your workplace.

Why Do Welding Cables Need Protectors?

Cables supply consistent power to welding equipment, which is often in environments that have extreme temperatures and hazards. It’s important to maintain the power to the welding equipment to avoid any disruptions in process efficiency.

Welding cables must be protected from these elements with heavy-duty cable protectors (which we’ll explain in better detail in a bit). Welding cable protectors helps prevent wear and tear, decreasing the amount of maintenance needed and boosting the longevity of operations.

6 Common Hazards of Welding Cables and Their Consequences

The welding industry serves many sectors, from aerospace to automotive to manufacturing. These industries all present different hazards to the connections that power these spaces. Without adequate planning and protective measures, like adding a welding torch cable cover to your setup, serious consequences could come your way.

These are the most common hazards to unprotected welding cables:

Use the Right Abrasion-Resistant Hose

There are industry standards for welding cable handling that outline best practices to prevent abrasion and physical damage. These include the best practices to store, coil, and elevate them, as well as the use of protective solutions like lead covers to shield cables from sparks and heat.

When these standards aren't met, cables could be dragged across rough surfaces, hit with heavy equipment, and brushed against sharp edges. These hazards can lead to exposed conductors, electrical shorts, and cable failure.

Extreme Temperatures

Welding operations may involve very high temperatures, ranging from 3,000 to 6,000 degrees Fahrenheit, causing sparks that can have a significant effect on welding cables.

Prolonged exposure to intense heat can deteriorate the cable insulation, exposing the internal wires to these intense conditions. The same thing can happen if the cables are exposed to extremely cold environments. The coldness can reduce the flexibility of the cables, which can lead to insulation cracking. Without the proper welding cable cover, these issues can compromise performance and increase the risk of safety hazards.

Chemical Exposure

Welding exposes cables to chemicals, oils, and other corrosive substances that are a part of many industrial settings. Welding creates fumes, which in turn release toxic gases from the metals and coatings, causing potential chemical reactions. These toxins and chemicals can wear down the insulation and compromise the integrity of the cable.

UV Radiation and Weathering

If you weld outdoors, this exposes the cables to the sun and precipitation. Prolonged exposure to sun can lead to damage from the UV rays, which break down the insulation of the cables. Rain and humidity can affect that welding cable, too, not only wearing down the insulation, but also allowing for moisture to get inside.

Electrical Overload and Mechanical Stress

Welding Cables can malfunction when power sources are overloaded or there is improper handling, tension, or kinking in the line. Electrical overloads are particularly dangerous because of the fire hazard they create. When welding cables overheat, it can also lead to insulation damage, exposing the internal wires. This will decrease performance and increase the risk of short-circuiting, equipment failure, and accidents.

Human Error and Improper Use

Employees are involved in the welding process must ensure everything is set up properly.

- Is the correct size cable being used?

- Are all the cables tucked away securely?

- Are any of the welding cables damaged?

Human error in these steps can lead to serious consequences. Using damaged cables or machines with improper connections can lead to equipment malfunctions, premature wear, and safety hazards. Further damage, accidents, and interruptions to productions could happen.

Solutions to Protect Your Welding Cables

Keeping a strict maintenance schedule and using protective accessories are key to protecting your welding cables. This makes for a safer and more efficient worksite.

Welding cable wraps are designed for quick and easy installation, specifically a hook-and-loop latch. Most can be tailored to your needs. You simply have to cut the sleeve to the desired length and wrap it around the cables.

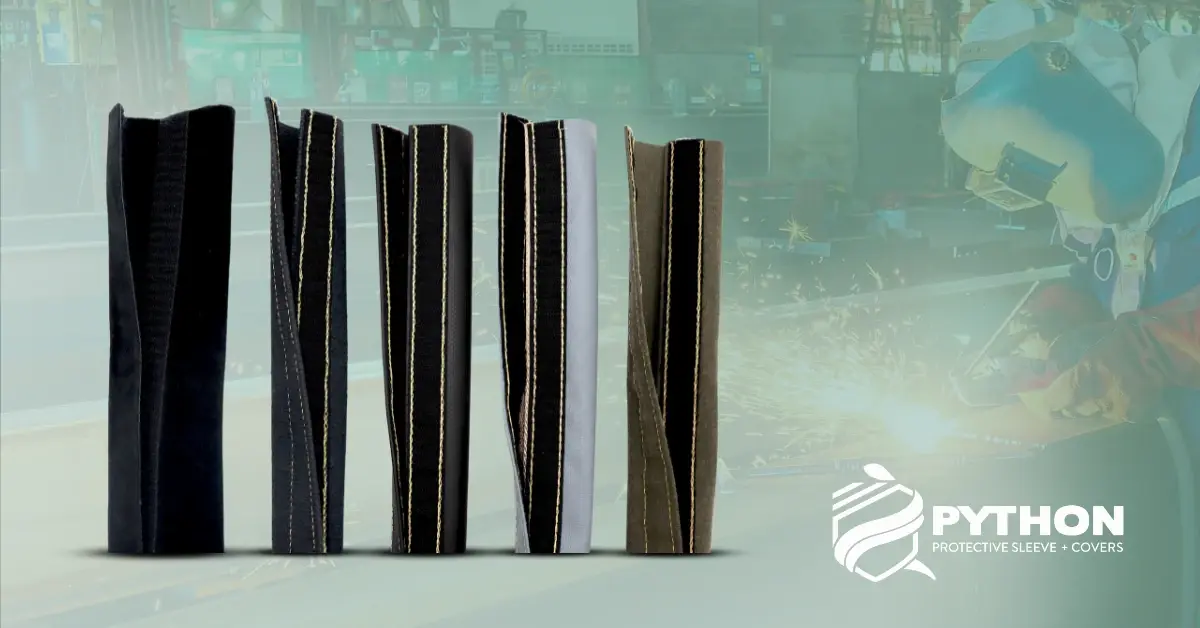

Welding cable covers come in a variety of materials that are suitable for many different applications, offering welding cable protection and a clean and organized setup. Wrap covers are used for welding cables that will be exposed to sparks, heat, abrasion, and sharp objects.

There are several types of welding cable wraps available, all designed specifically to extend the life of your cables. Covers from our Weld Armor series include:

- Leather: This material is best overall for high-abrasion and high-heat environments. The innovative hook-and-loop fastener is welded to the sleeve, this replaces the common weakness of sewn seams, ensuring durability in extreme conditions.

- Neoprene: Neoprene is best for high-abrasion environments when there is low to medium spark in the welding process.

- Canvas: Canvas is ideal for medium abrasion environments and when the welder's leads are suspended and can drag on the floor, table, or equipment.

- Acrylic: This is most suitable for high-heat environments, low to no-abrasion projects, and can handle continuous temperatures of up to 1000 degrees Fahrenheit.

- Teflon: Teflon is best for high-heat environments, in applications with light to medium grinding and torches with a flame. This wrap is lightweight, flexible, and can withstand continuous temperatures up to 600 degrees Fahrenheit.

Consider Python for Your Welding Cable Protector Needs

Welding worksites are filled with hazards, ranging from extreme temperatures to corrosive chemicals. A vital part of maintaining both efficiency and safety on the job is to protect the welding cables from these various hazards.

There are many options available to protect your welding cables and to keep them organized. Budget and application are the two primary factors that should guide your choice. Your welding products supplier should offer a variety of wraps, sleeves, and straps to match your exact use case.

Explore our product catalog to find out how to best safeguard your welding cables and equipment. Want to discover more? Contact us today to learn about our hose protection solutions and accessories.