Hydraulic hose pinhole leaks are a serious safety concern and require immediate action. Hydraulic fluid is an essential factor in the operation of many machines, including power tools, vehicles, and industrial machinery. A pinhole leak in a hose or tubing can cause a rapid loss of pressure that can be dangerous to the operator. In some cases, this can lead to serious accidents.

In this article we will discuss:

External vs Internal Leaks

The term “pinhole leaks” is a blanket term. While a leak is a leak, with pinhole leaks in hydraulic hoses there are two to be aware of: external and internal. Each poses unique considerations for repair and safety.

External leaks occur at the surface of the hose and can be easily identified because they are visible. This type of leak often occurs from wear and tear or damage caused by abrasion.

Internal pinhole leaks, on the other hand, occur inside the walls of the hose. They are harder to detect, as they may not be visible from the outside. Internal pinhole leaks can be caused by damage to the internal lining of the hose.

Hydraulic Hose Pinhole Leak Injuries: Don’t Use Your Hand to Check for Leaks

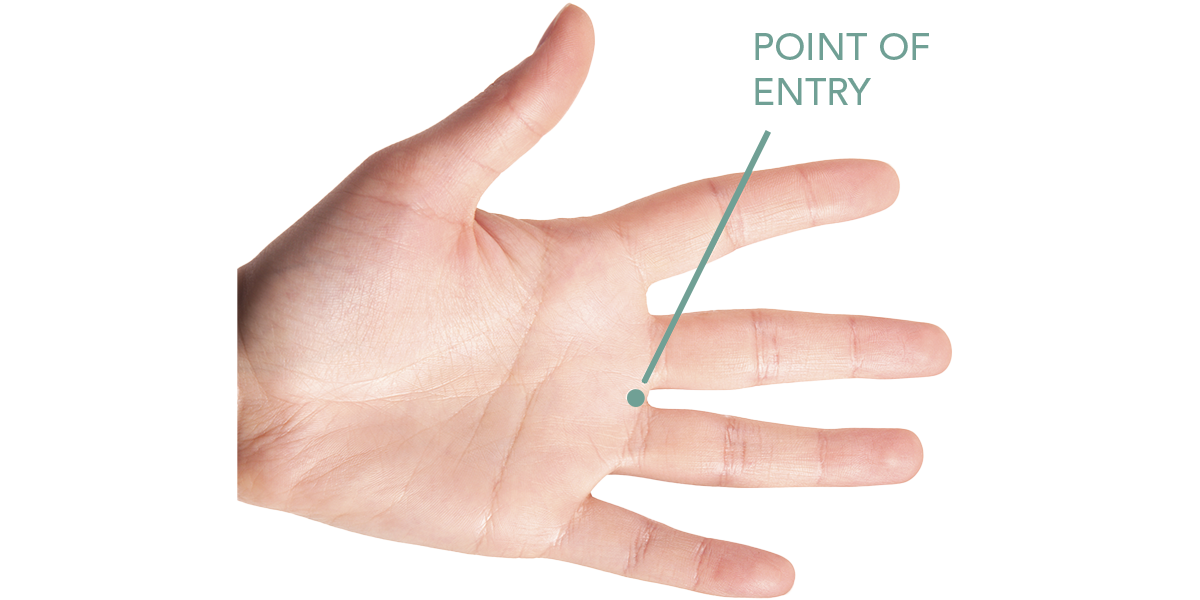

What’s one of the most dangerous ways to check for a pinhole leak? Using your hand.

Using your hand to check for pinhole leaks in hydraulic hoses can be a dangerous endeavor and should always be avoided. Though pinhole leaks are very small, they can still cause serious injury if the user is not careful.

Hydraulic fluid is highly pressurized, and when it’s released through a pinhole leak, it can spray out with great force. This can cause cuts, burns, and other injection type injuries.

how to Repair a Pinhole Leak: 6 Steps

A pinhole leak may not seem like a significant issue, but a single extra turn of the wrench can make an already problematic leak into a real concern. That could mean time and money lost.

When a leak is identified, it creates many headaches, including downtime on the job site. To fix a hydraulic hose pinhole leak efficiently and reduce possible downtime, follow these steps:

1. Depressurize the System

Hydraulic hose pinhole leaks put workers at risk and should be addressed immediately. When a pinhole leak is discovered, depressurize the system as quickly and safely as possible. Doing so can help prevent further pressure loss and potential injury.

2. Inspect the Hose

Once the system has been depressurized, check the entire length of the hydraulic hose for signs of leakage or damage. Look for any:

- Cracks

- Tears

- Bubbles

- Wet patches

Pay careful attention to connections and the ends of the hose.

3. Replace the Hose

If a pinhole leak is identified, check the specification of the system to make sure you’re replacing it with an appropriately sized hose. Make sure to check for compatibility with fluid type and pressure rating as well. Once you have selected the correct replacement, install it in accordance with all safety protocols.

4. Fittings: Clean and Replace as Needed

When a pinhole leak is discovered in a hydraulic hose, it’s important to also check the fittings for signs of damage or potential leakage. The fittings are responsible for providing a secure connection between the hose and other components, and any damage or corrosion should be addressed immediately.

5. Check Pressures – and Check Again

Once the repair is complete, check the pressure of the system to ensure it is back up to spec. It’s also important to check for any further signs of leaks or damage in the coming days and weeks after installation, as these can often go unnoticed until they become larger problems.

6. Preventative Maintenance

Regular checkups and preventative maintenance of hydraulic hoses can help identify and address potential pinhole leaks before they become serious safety issues. Check the system regularly for signs of wear, tear, or corrosion, as these can all cause pinhole leakage over time.

In addition, check the fluid levels regularly to ensure that there are no leaks or other issues. If any sign of leakage is present, take immediate action.

Prepare Now, Skip Hydraulic Hose Pinhole Leaks Later

Employee safety and avoiding downtime are both priorities on the job site. They’re also top priorities when pinhole leaks occur.

Knowing the difference between external and internal leaks and following the right steps to deal with pinhole leaks can improve safety and get the job back on track quickly.

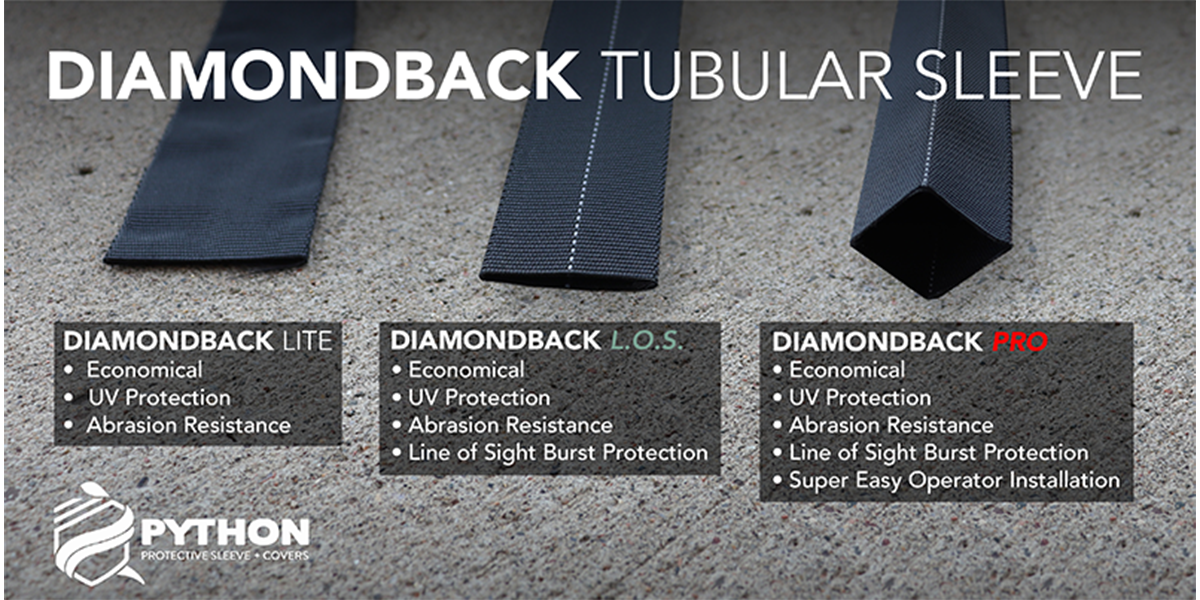

Don’t Skimp on Safety: Python Values Line of Sight

Be sure to avoid searching for the hydraulic hose pinhole leak by hand and protect your employees with Python's line of pinhole and burst protection tubular sleeves.

Learn More: Line of Sight testing can keep operators safe on the job - even when they are working in tight spaces.